A joint control method of sintering desulfurization and main exhaust fan

A main exhaust fan and combined control technology, applied in furnace control devices, lighting and heating equipment, furnaces, etc., can solve the problems of positive pressure in the desulfurization tower, affecting the sintering process, and fluctuation of negative pressure in the desulfurization system, avoiding positive pressure, Improve the effect and ensure the effect of negative pressure value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the above features and advantages of the present invention more obvious and understandable, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific examples:

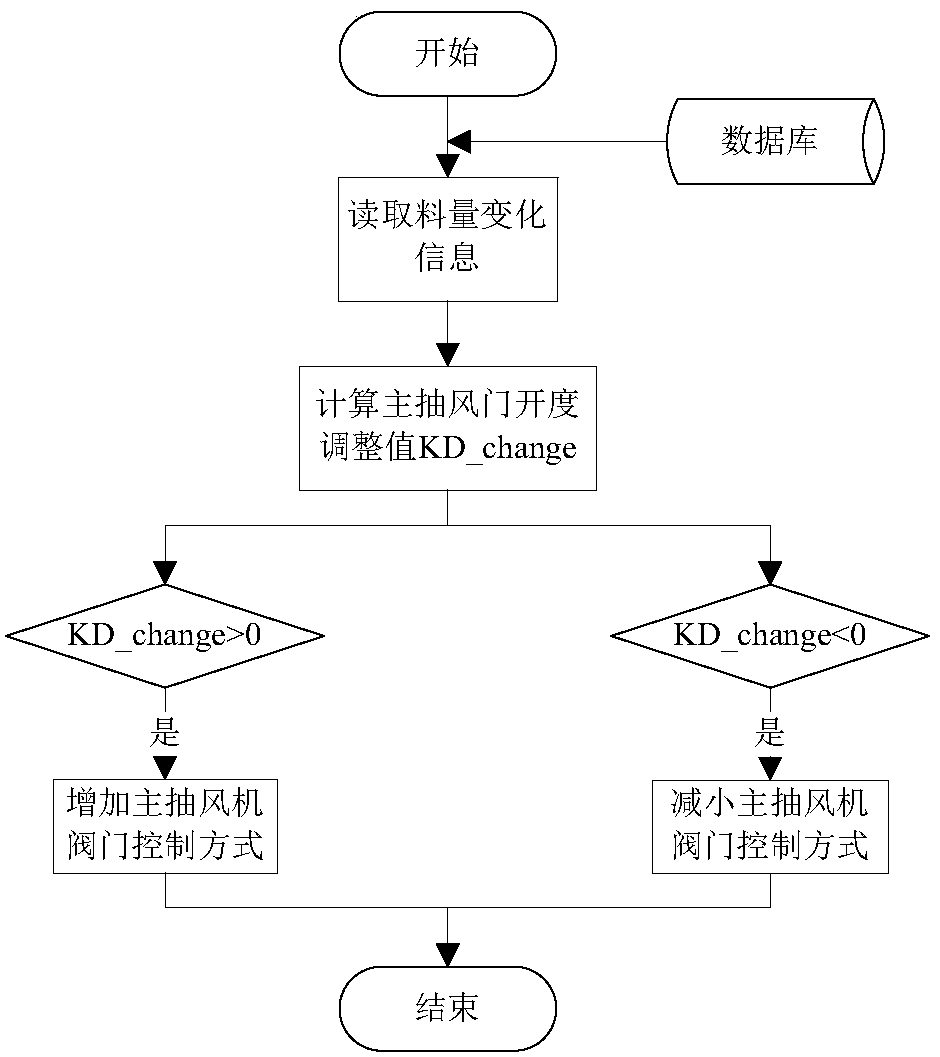

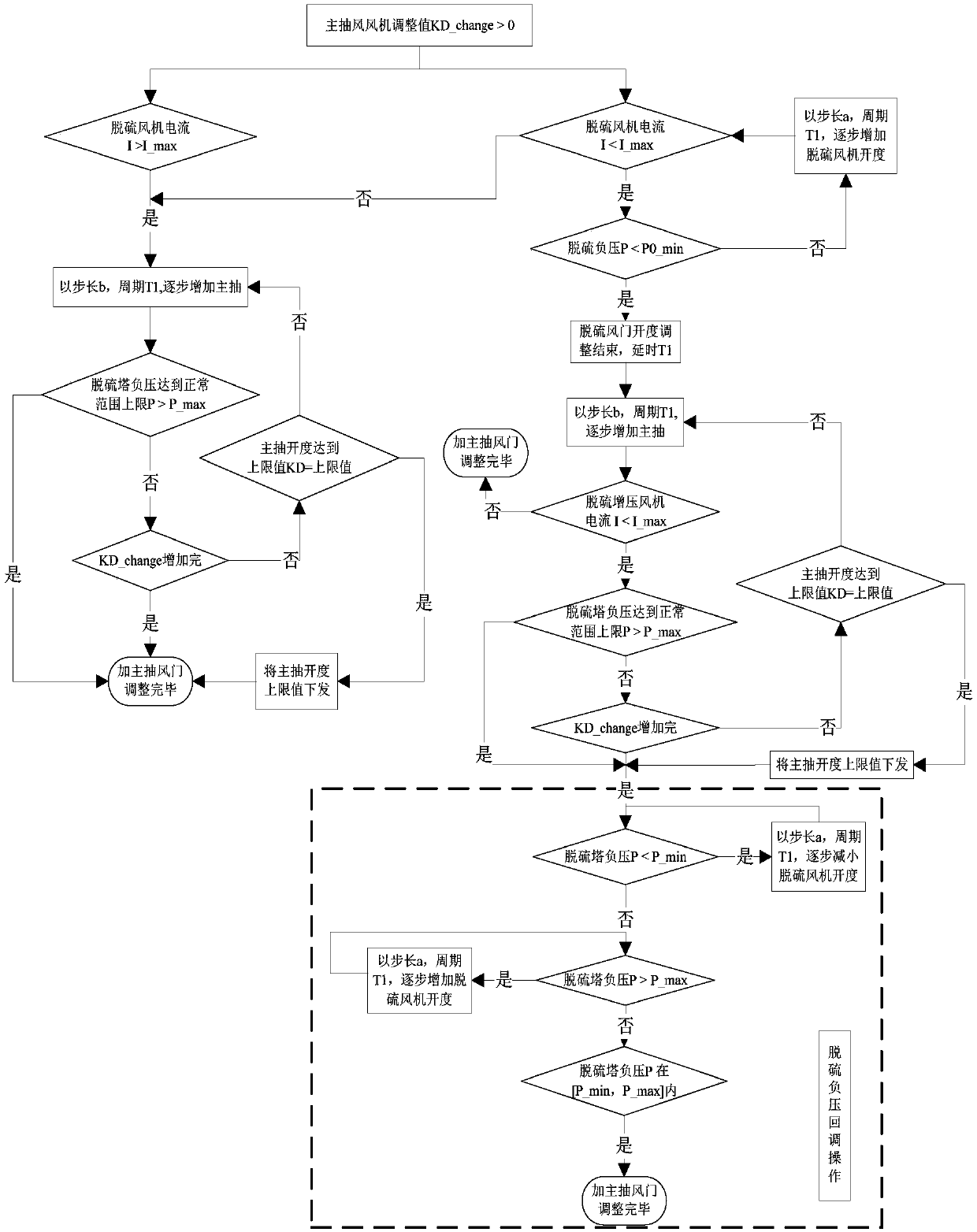

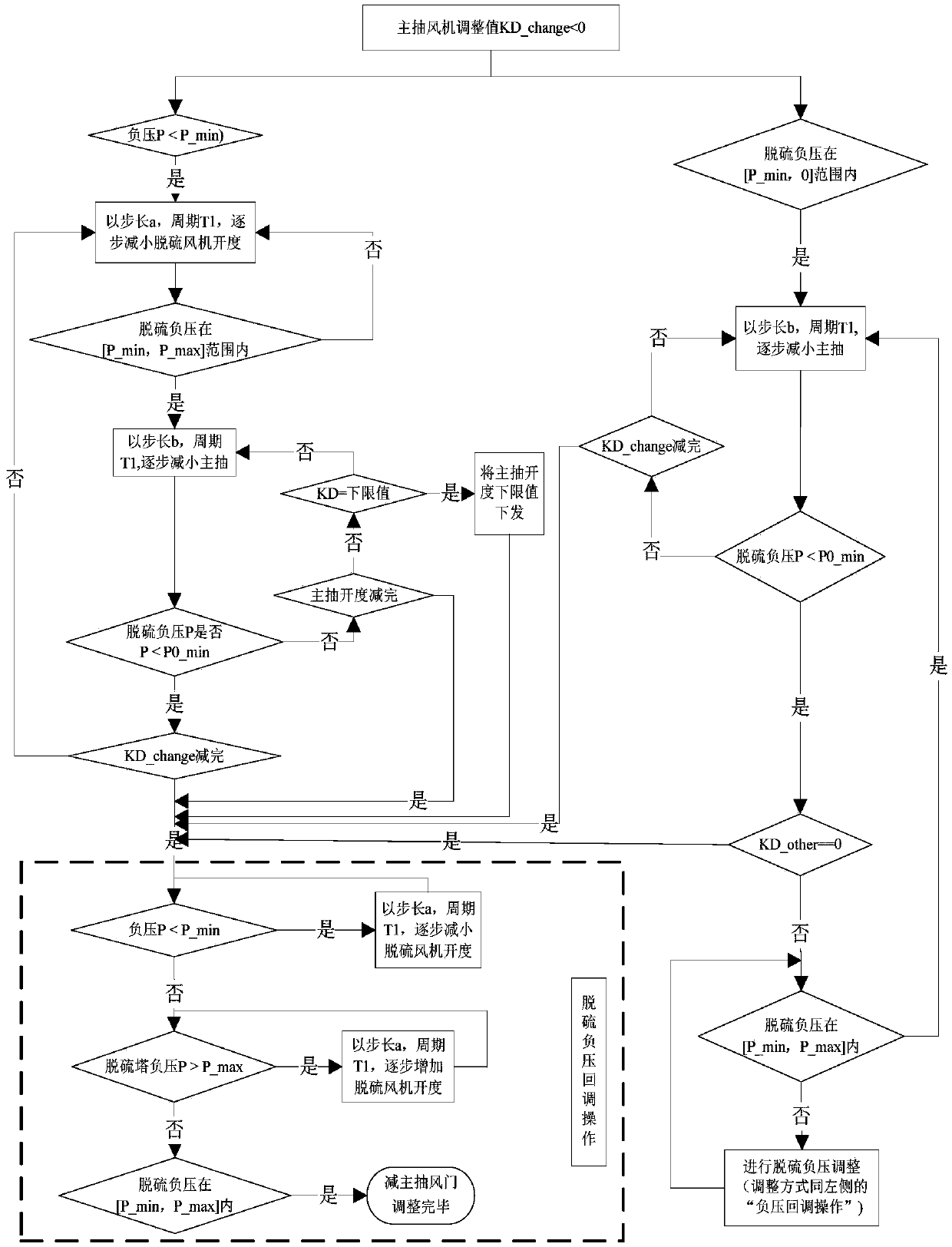

[0035] The combined control method of a sintering desulfurization and the main exhaust fan, the operation steps are as follows:

[0036] Step 1: Control parameter setting, calculate the adjustment value of the valve opening of the main exhaust fan according to the change of the total material volume of the sintering machine:

[0037] The control parameters mainly include: the allowable maximum current value I_max of the desulfurization fan, 155A; the adjustment step size of the desulfurization fan valve a, 3%; the adjustment step size b of the main exhaust fan valve, 3%; the allowable minimum negative pressure value P0_min of the desulfurization tower, -1000Pa; the lower limit value of the normal range of desulfurization tower neg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com