Refined processing method of green tea

A processing method and green tea technology are applied in the field of refined green tea processing, which can solve the problems of low quality and unstable quality of refined tea, and achieve the effects of low moisture content, ornamental value, and promotion of tea aroma and ripening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

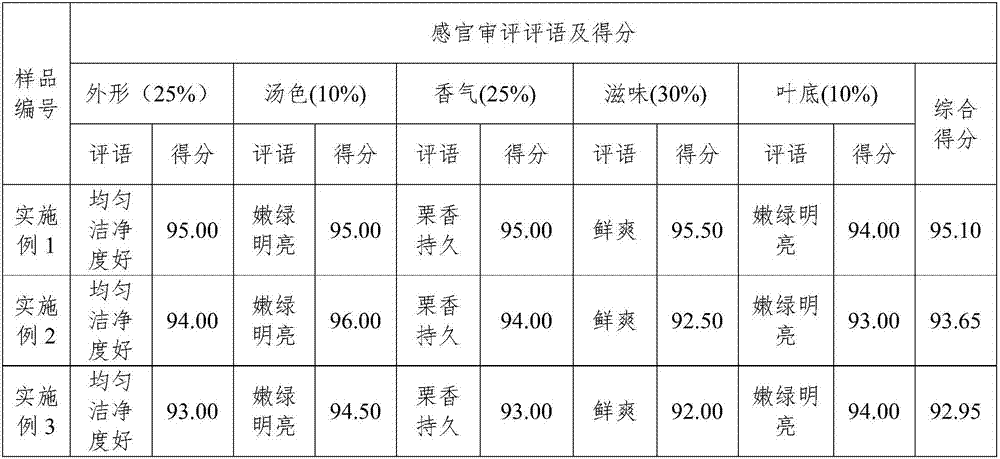

Embodiment 1

[0031] The refined processing method of green tea of the present invention comprises the following steps:

[0032] (1) Picking of fresh leaves: select and pick the tender green fresh leaves with one bud and one leaf or one bud and two leaves of the tea tree varieties picked before the Qingming Festival, and sort and pick according to the variety and batch;

[0033] (2) Withering: In an indoor air-conditioned room, spread the picked fresh leaves evenly and thinly in the withering tank, set the temperature at 20-25°C, spread the thickness of 2-5cm, spread the time for 8 hours, turn it once every 0.5, and use Knead once by hand, so that the water content of the tea leaves is 70-85%, and the fresh leaves are wilted;

[0034] (3) Roller fixation: Use a roller fixer to fix the withered tea greens. The fixation temperature is 240-260°C, and the time is 0.5min. Then reduce the finish temperature to 120-130°C, and the time is 2min. Turn from green to dark green, the leaves are soft ...

Embodiment 2

[0045] The refined processing method of green tea of the present invention comprises the following steps:

[0046] (1) Picking of fresh leaves: select and pick the tender green fresh leaves with one bud and one leaf or one bud and two leaves of the tea tree varieties picked before the Qingming Festival, and sort and pick according to the variety and batch;

[0047] (2) Withering: In an indoor air-conditioned room, spread the picked fresh leaves evenly and thinly in the withering tank, set the temperature at 18-20°C, spread the thickness of 3-5cm, spread the time for 5 hours, turn it once every 1 hour, and use Knead once by hand, so that the water content of the green tea is 80-85%, and the fresh leaves are wilted;

[0048] (3) Roller fixation: Use a roller fixer to fix the withered tea greens. The fixation temperature is 250-260°C and the time is 0.5min. Turn from green to dark green, the leaves are soft and sticky, the green grass disappears, and when the tea fragrance is ...

Embodiment 3

[0059] The refined processing method of green tea of the present invention comprises the following steps:

[0060] (1) Picking of fresh leaves: select and pick the tender green fresh leaves with one bud and one leaf or one bud and two leaves of the tea tree varieties picked before the Qingming Festival, and sort and pick according to the variety and batch;

[0061] (2) Withering: In an indoor air-conditioned room, spread the picked fresh leaves evenly and thinly in the withering tank, set the temperature at 22-25°C, spread the thickness of 2-5cm, spread it for 5 hours, and turn it once every 0.8 hours. And knead once by hand, so that the water content of the green tea is 70-85%, and the fresh leaves are wilting;

[0062] (3) Roller fixation: Use a roller fixer to fix the withered tea greens, the fixation temperature is 240-250°C, and the time is 1min, then reduce the finish temperature to 130-140°C, the time is 3min, until the leaf color changes from The green color turns d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com