Automatic frame pressing device, automatic frame centering and pressing device and automatic frame centering and pressing system

A pressing device and automatic centering technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as difficulty in ensuring product quality, failure to meet market demand, waste of human resources, etc., to improve customer satisfaction, The effect of saving manpower and saving investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

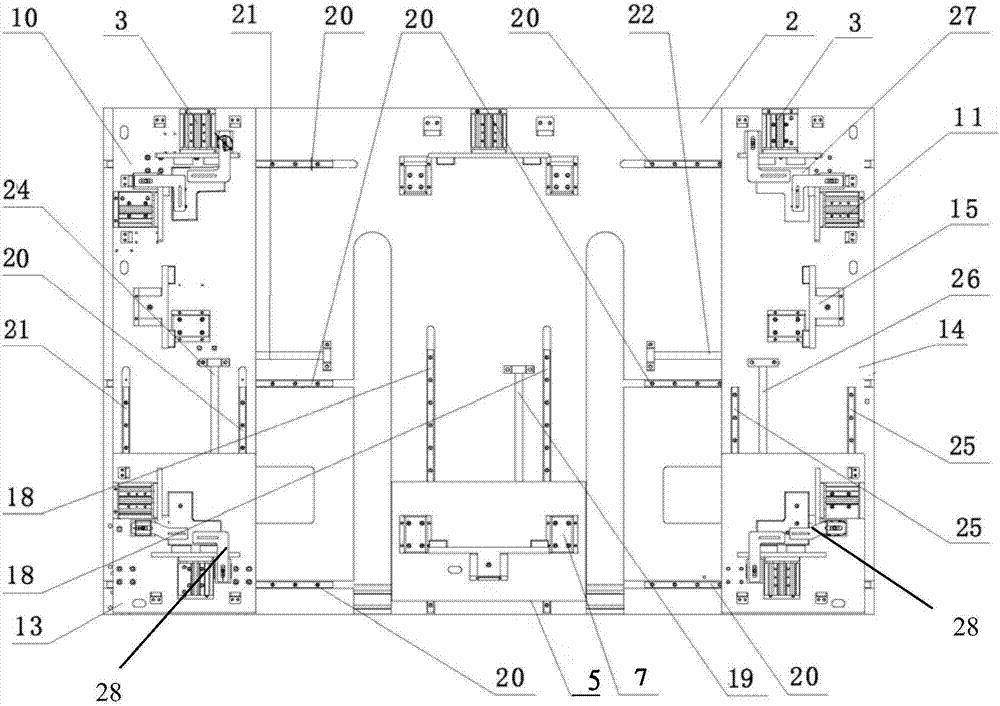

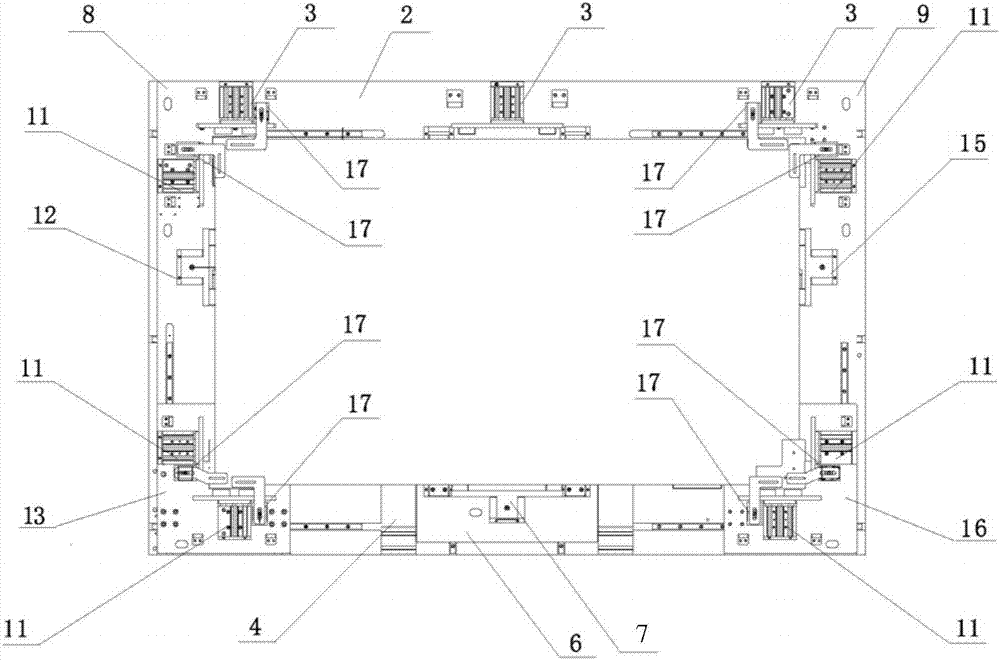

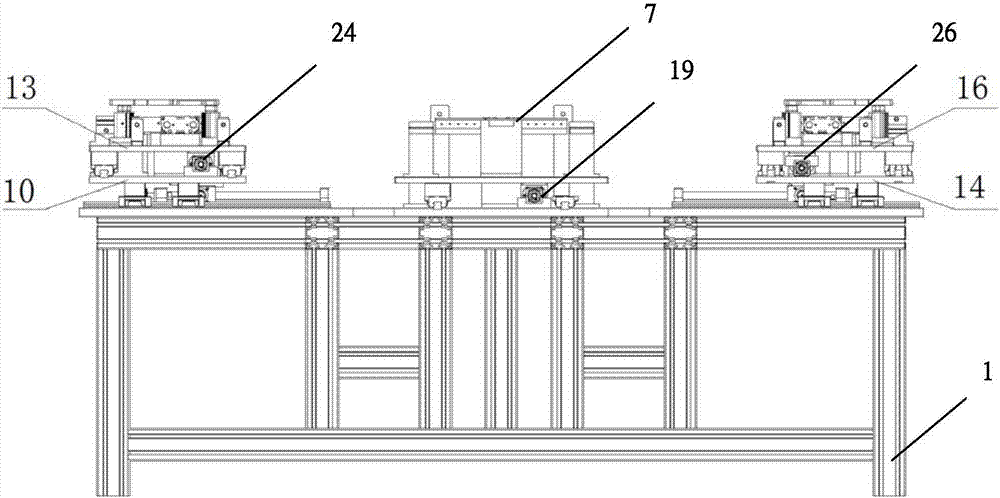

[0049] Such as Figure 1-4 , an automatic frame pressing device, characterized in that the device includes a table 2 supported by a bracket 1, and a plurality of ball screws driven by servo motors,

[0050] The rear edge of the table 2 is provided with a rear positioning cylinder 3, and the rear positioning cylinder 3 is located on the central axis of the table 2;

[0051] A pair of slots 4 are arranged symmetrically on both sides of the central axis on the table 2, and the slots 4 lead to the front edge of the table 2;

[0052] On the front side of the table and between the two slots 4, there is a Y-direction propulsion device 5 that slides back and forth along the central axis, that is, the Y direction, and the Y-direction propulsion device 5 includes a The Y-direction slide plate 6 and the Y-direction push block 7 above it;

[0053] A centering device is also provided on the table top 2, and the automatic centering device includes an X-direction left propulsion device 8 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com