A kind of preparation method of layered double metal hydroxide and its prepared product

A layered bimetal and hydroxide technology, which is applied in the direction of oxide/hydroxide preparation, chemical instruments and methods, aluminum compounds, etc., can solve the problems of limited application and disordered arrangement, and achieve regular arrangement, neat edges, The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The present invention provides a kind of preparation method of layered double metal hydroxide, comprising:

[0023] mixing a trivalent metal hydroxide and a divalent metal salt with a buffer solution having a pH value between 9-10 to obtain a reaction mixture;

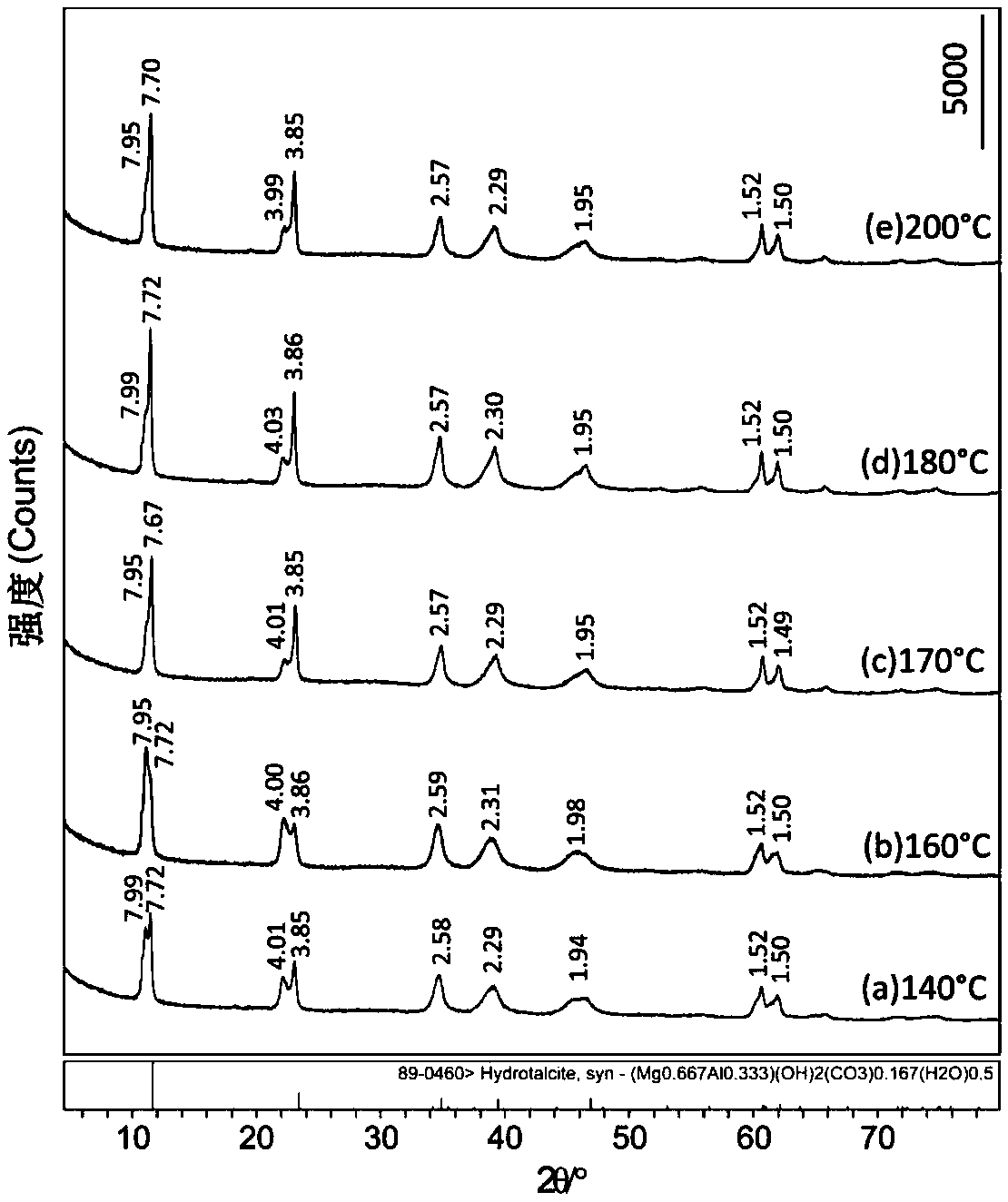

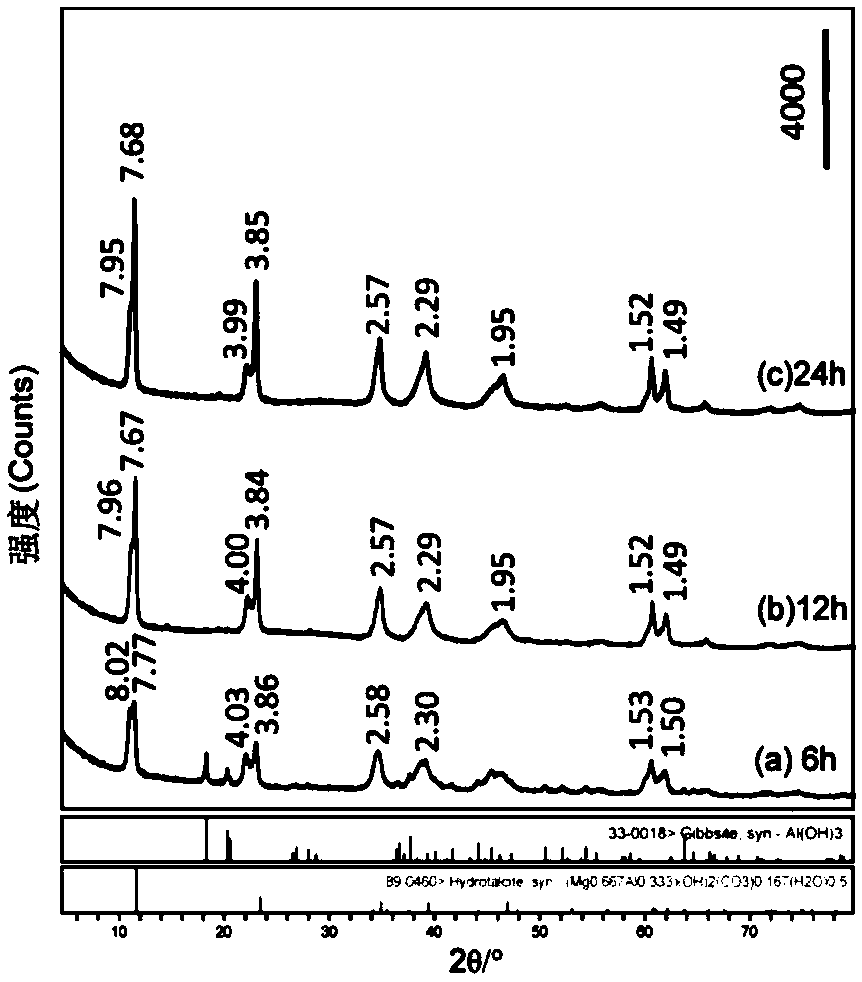

[0024] React the obtained reaction mixture at a temperature of 100-300° C. for more than 10 hours. After the reaction is completed, separate and wash to obtain a layered double metal hydroxide.

[0025] In a specific embodiment, the trivalent metal hydroxide is selected from Al(OH) 3 , Cr(OH) 3 , Fe(OH) 3 , V(OH) 3 、Co(OH) 3 、La(OH) 3 and Ti(OH) 3 At least one of them, preferably one or two, more preferably one. In a specific embodiment, the divalent metal salt is dissolved in a buffer solution and is selected from Mg 2+ , Ca 2+ 、Sr 2+ 、Ba 2+ , Zn 2+ 、Ni 2+ , Fe 2+ 、Cu 2+ 、Co 2+ , Mn 2+ At least one of sulfate, nitrate, carbonate or chloride, preferably one or two, more preferably one. In a spe...

Embodiment 1

[0036] Prepare buffer solution

[0037] Weigh 14.0g NH 4 Cl, add 9.6mL NH 3 ·H 2 O, diluted to 200mL with deionized water, stirred evenly by magnetic force to obtain NH 3 ·H 2 O-NH 4 Cl buffer solution, the pH of the solution was measured with a pH meter=9.30.

Embodiment 2

[0039] Preparation of MgAl-LDH

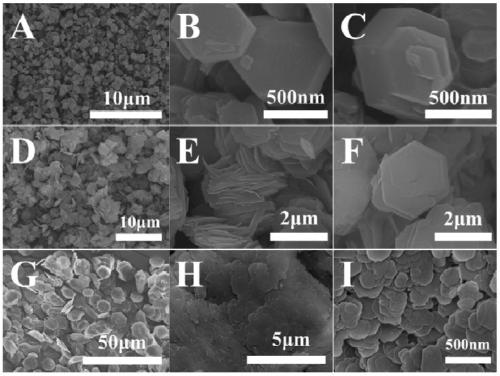

[0040] Add 0.1950g (2.5mmol) Al(OH) to 50mL buffer solution 3 and 1.9232g (7.5mmol) Mg (NO 3 ) 2 ·6H 2 O, fully stirred evenly, added 0.4500g (11.25mmol) NaOH, stirred evenly, poured into a 100mL hydrothermal kettle, and the mixed solution was hydrothermally reacted at 140°C for 24h. After the reaction was completed, it was cooled at room temperature, the product was centrifuged, washed 5 times with deionized water, and then dried in an oven at 70° C. for 24 hours to obtain a white solid powder MgAl-LDH.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com