Rotatable water-cooling type electrode device for evaporator

A technology of electrode device and rotating device, which is applied in the direction of vacuum evaporation plating, ion implantation plating, metal material coating technology, etc., can solve the problems of inability to perform automatic cooling, etc., so as to improve the range of use, improve the heat dissipation effect, reduce the The effect of the loss of current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

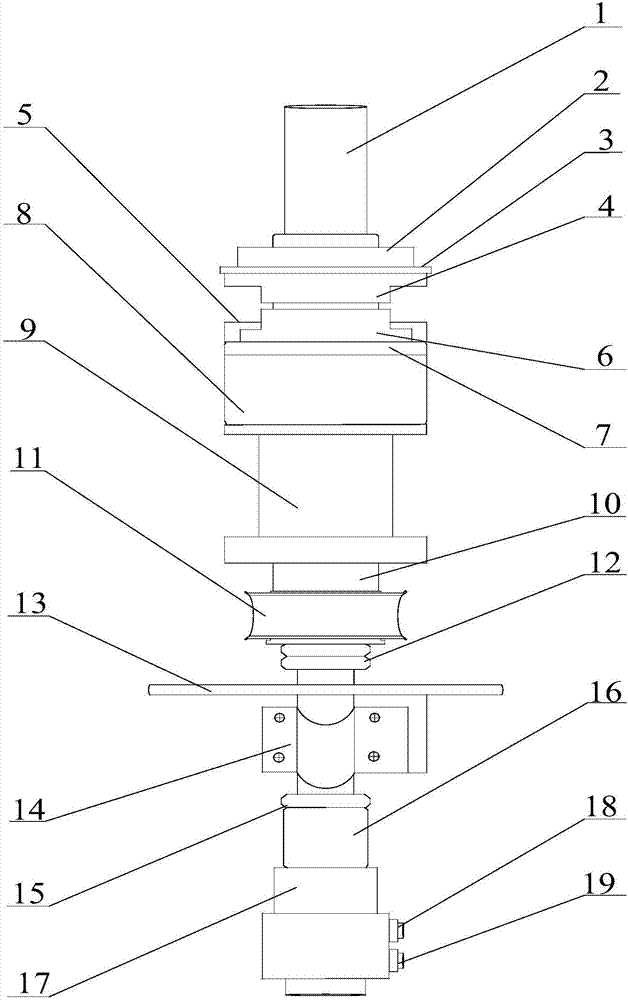

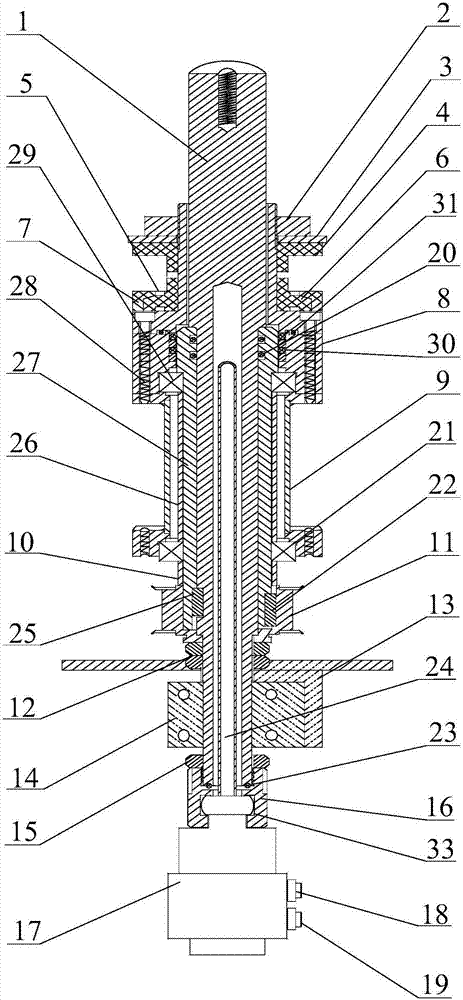

[0025] Such as figure 1 , 2 As shown, the present invention discloses a rotatable water-cooled electrode device for an evaporator, which mainly consists of a support cylinder 9, an electrode rod 1 arranged in the support cylinder 9, a power connection device arranged on the electrode rod 1, and a The mounting assembly on the support cylinder 9 is formed. Wherein, a water-cooling device is provided on the electrode rod 1, and the water-cooling device is as figure 2 Said 2 includes a water inlet pipe 24 , a transition seat 16 , and a rotary water joint 17 . A rotating device matched with the electrode rod 1 is also arranged in the supporting cylinder 9, such as figure 2 As shown, it includes a rotating vacuum-sealed outer casing 8 , a rotating inner shaft 27 , and a timing pulley 11 . The electrical connection device such as figure 2 As shown, it includes an electrode hoop 14 and an annular electrode disc 13 .

[0026] Such as figure 2 As shown, the electrode rod 1 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com