Impeller

A technology of impellers and blades, applied in the field of turbochargers, which can solve the problems of not being able to achieve large flow and high boosting ratio, not being able to increase engine power, and increasing the weight of the vehicle body, and achieve improved power performance, strong power performance, and environmental protection performance Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

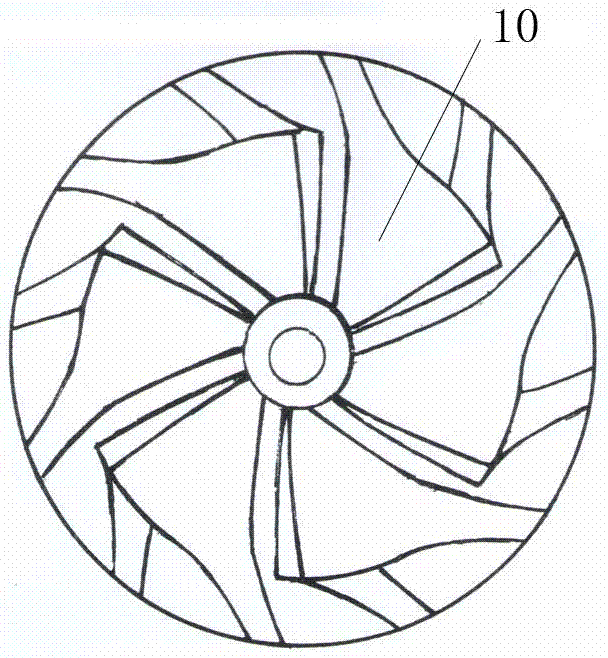

Image

Examples

Embodiment 1

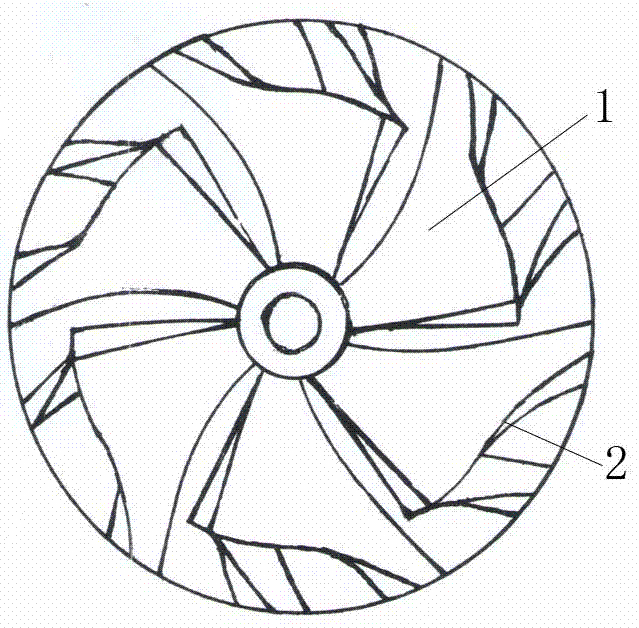

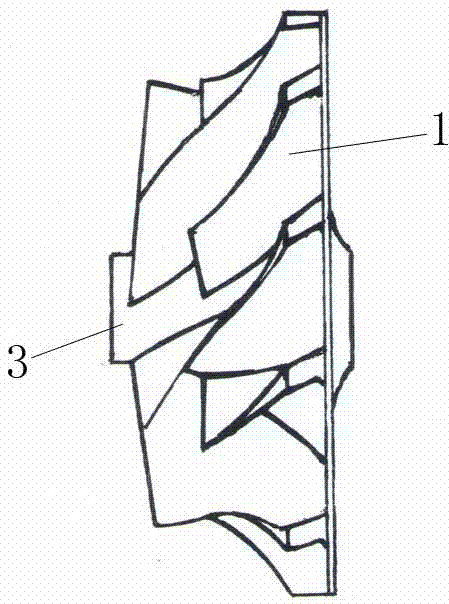

[0017] Such as figure 2 As shown, an impeller of the present invention includes a circular impeller surface, a blade 1 , a runner inlet 2 and a hub 3 . Such as image 3 As shown, the blades are composed of long blades and short blades, and the long blades and short blades are arranged at intervals and twisted in the same direction. The head end of the blade is installed on the hub, and the thickness of the blade 1 gradually increases from the head end to the end. The thickness ratio between the head end and the end of the blade 1 is 1:1.2.

Embodiment 2

[0019] In this embodiment, the thickness ratio between the head end and the end of the blade 1 is 1:1.5, and the rest are the same as in Embodiment 1.

Embodiment 3

[0021] The thickness ratio between the head end and the end of the blade 1 described in this embodiment is 1:1.3, and the rest are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com