Brake built-in type rotating table and braking control method thereof

A technology of rotary table and brake, which is applied to brake actuators, manufacturing tools, metal processing equipment, etc., can solve the problem that the structural rationality of rotating parts needs to be improved, and the braking reliability and stability of the braking mechanism need to be improved. and other problems, to achieve the effect of large hydraulic braking torque, high braking reliability and strong stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

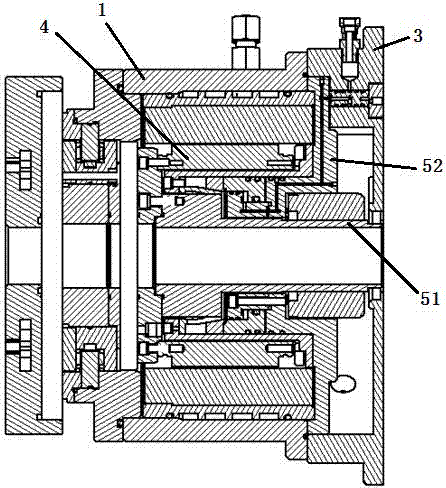

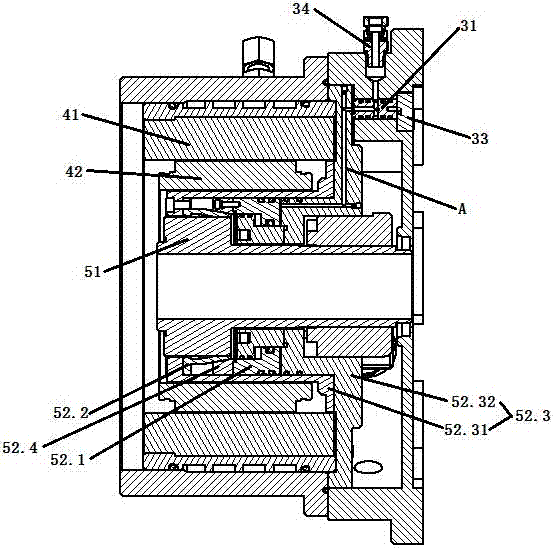

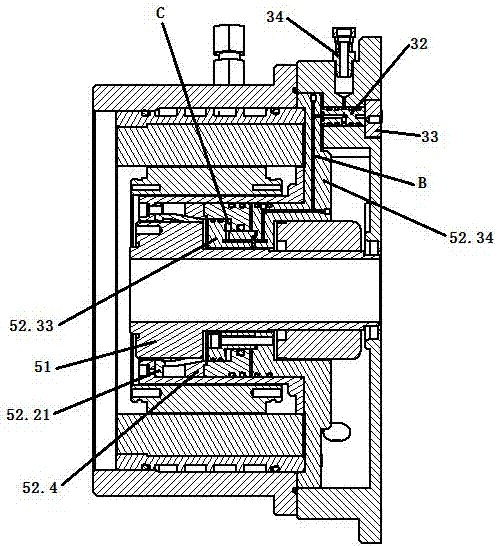

[0035] Combine below Figure 1 to Figure 4 Embodiments of the present invention are described in detail.

[0036]The built-in brake rotary table includes a housing 1, which is equipped with a rotatable rotating part 4 and a hydraulic brake assembly 52. The hydraulic brake assembly 52 is fixed to the right side of the housing 1. The rotating part 4 includes a torque motor stator The rotor 42 in 41 is characterized in that the brake shaft 51 is coaxially fixed in the rotor 42, and the hydraulic brake assembly 52 is sleeved on the outer circumference of the brake shaft 51, including the piston 52.1, the piston 52.1 on the left side The internal expansion brake sleeve 52.2 and the hydraulic cylinder 52.3 fixed to the housing 1, the piston 52.1 is arranged in the hydraulic cylinder 52.3 and is hydraulically sealed with the hydraulic cylinder 52.3 by a sealing ring, and the internal expansion brake sleeve 52.2 It is fixed with the hydraulic cylinder block 52.3 and arranged betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com