Low-temperature methanol washing technology capable of efficiently recycling pressure energy and cold energy

A low-temperature methanol washing, pressure energy technology, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve problems such as pressure loss, and achieve high yield, safe and reliable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

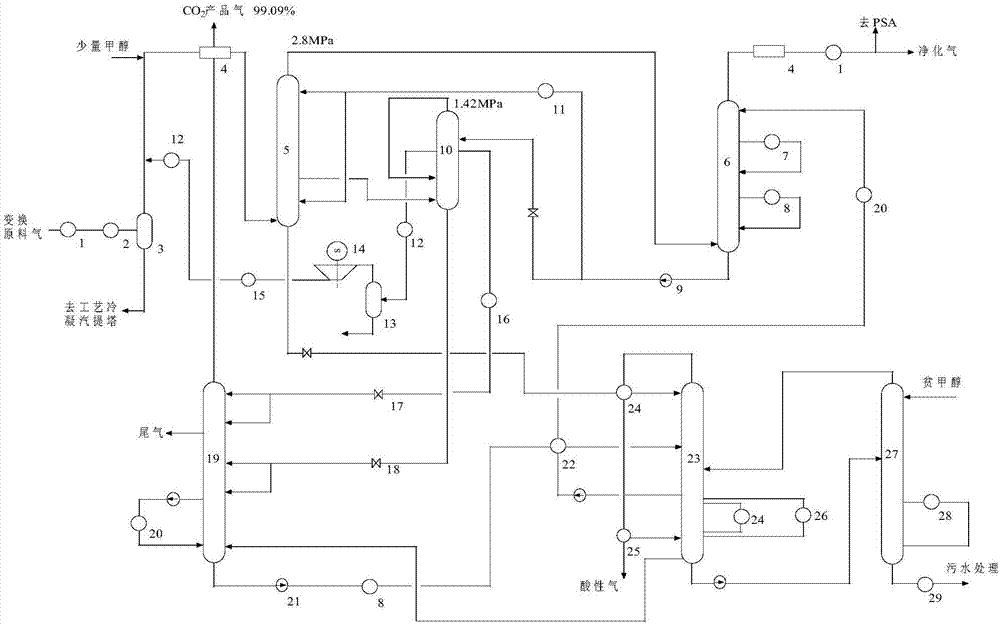

Method used

Image

Examples

Embodiment

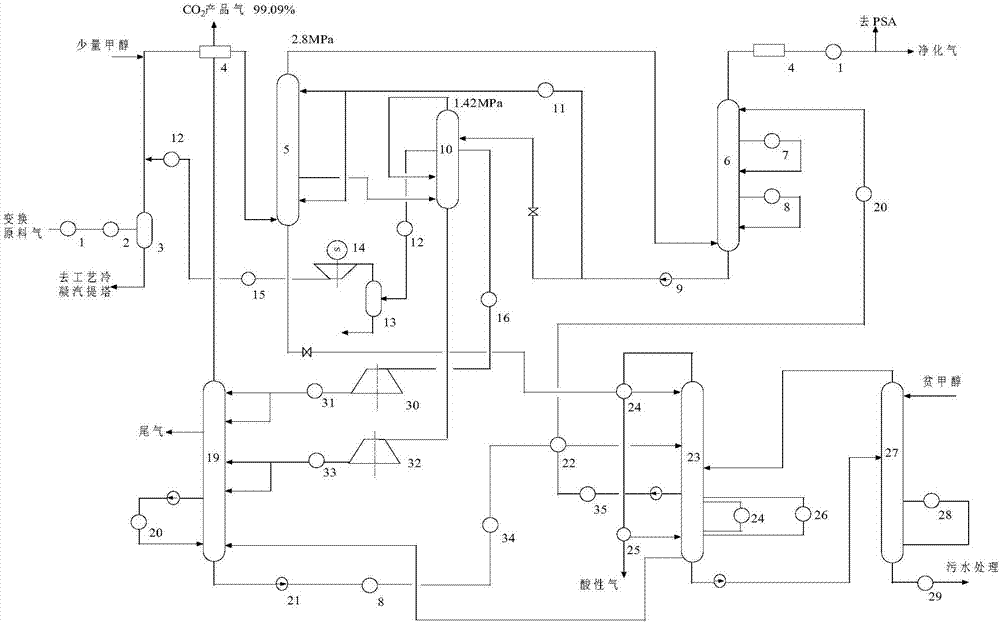

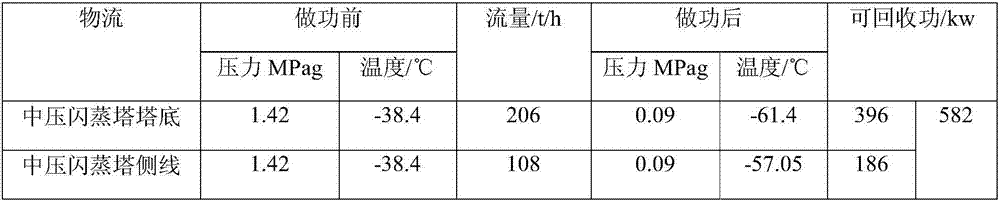

[0030] The present embodiment has carried out the following improvements compared to the comparative process:

[0031] (1) H-rich at the bottom of the medium pressure flash tower 10 2 S / CO 2 Methanol (206t / h, 1.42MPag, -38.4℃) enters CO after being throttled by throttle valve 18 (206t / h, 0.09MPag, -61.4℃) 2 The regeneration tower 19 is adjusted to be rich in H at the bottom of the medium pressure flash tower 10 2 S / CO 2 Methanol (206t / h, 1.42MPag, -38.4°C) is advanced and newly added hydraulic turbine 32, and after expansion work (206t / h, 0.09MPag, -64.7°C), the newly added low-temperature circulating fluid (such as 4~ 10°C cold water) heat exchanger 33, after releasing the cooling capacity and heating up to the same level as before adjustment (206t / h, 0.09MPag, -61.4°C) into CO2 2 Regeneration Tower 19. To ensure CO 2 The operation of the regeneration tower 19 is not affected by this adjustment, and corresponding adjustment measures (such as bypass, etc.) are provided f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com