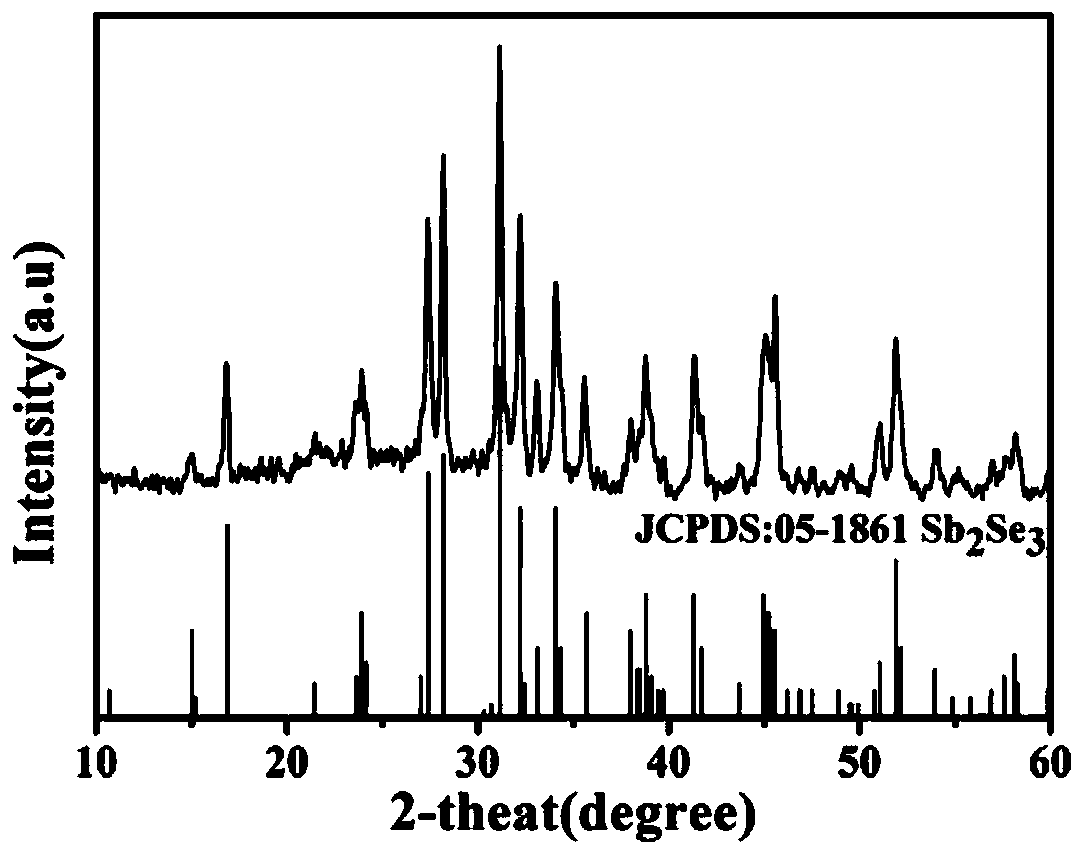

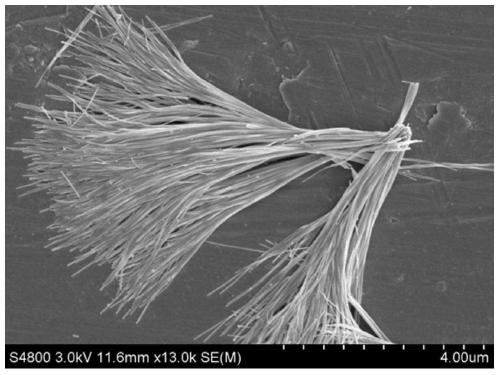

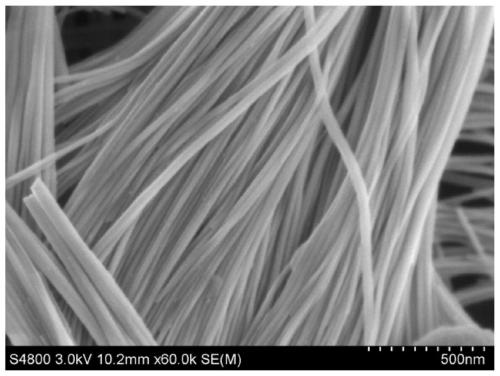

A microwave hydrothermal method for preparing beam-shaped antimony selenide electrode materials for sodium-ion battery negative electrodes

A sodium-ion battery, microwave hydrothermal technology, applied in battery electrodes, negative electrodes, nanotechnology for materials and surface science, etc., can solve the problems of poor cycle stability, limited wide application, etc., achieve full contact, shorten transmission path, the effect of improving electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1) Add 0.01g polyvinylpyrrolidone with an average molecular weight of 30000 and 0.1g sodium dodecylsulfonate into distilled water, ultrasonically shake (300W, 40°C, 60min) to completely dissolve and disperse evenly, add 0.0091g trichloro Antimony, mixed solution A is obtained under stirring (500r / min, 10min) conditions, and the concentration of antimony trichloride is controlled to be 0.001mol / L;

[0027] 2) Disperse 0.0104g of sodium selenite in 3mL of hydrazine hydrate with a mass concentration of 50%, and stir (500r / min, 10min) to obtain wine red solution B;

[0028] 3) Add the obtained solution B to the solution A dropwise under continuous stirring (500r / min, 60min) to obtain the mixed solution C;

[0029] 4) Put the mixed solution C into a microwave reactor with a volume filling degree of 40%, then seal the reactor, put it into a microwave hydrothermal reactor, and select the temperature control mode for reaction at a heating rate of 3°C / min The temperature was ...

Embodiment 2

[0031] 1) Add 0.05g of polyvinylpyrrolidone with an average molecular weight of 30,000 and 0.2g of sodium dodecylsulfonate into distilled water, ultrasonically oscillate (600W, 50°C, 50min) to completely dissolve and disperse evenly, and add 0.1027g of trichloro Antimony, mixed solution A is obtained under stirring (600r / min, 20min) conditions, and the concentration of antimony potassium tartrate is controlled to be 0.01mol / L;

[0032]2) Disperse 0.1167g of sodium selenite in 4mL of hydrazine hydrate with a mass concentration of 50%, and stir (600r / min, 10min) to obtain wine red solution B;

[0033] 3) Add the obtained solution B to the solution A dropwise under continuous stirring (600r / min, 50min) to obtain the mixed solution C;

[0034] 4) Put the mixed solution C into a microwave reactor with a volume filling degree of 45%, then seal the reactor, put it into a microwave hydrothermal reactor, select the temperature control mode to react, and use a heating rate of 5°C / min T...

Embodiment 3

[0036] 1) Add 0.1g of polyvinylpyrrolidone with an average molecular weight of 30,000 and 0.3g of sodium dodecylsulfonate into distilled water, ultrasonically oscillate (500W, 50°C, 40min) to completely dissolve and disperse evenly, and add 0.2281g of trichloro Antimony, mixed solution A is obtained under stirring (500r / min, 10min) conditions, and the concentration of antimony trichloride is controlled to be 0.02mol / L;

[0037] 2) Disperse 0.2594g of sodium selenite in 5mL of hydrazine hydrate with a mass concentration of 50%, and stir (500r / min, 30min) to obtain wine red solution B;

[0038] 3) The obtained solution B was added dropwise to the solution A under the condition of continuous stirring (500r / min, 40min) to obtain the mixed solution C;

[0039] 4) Put the mixed liquid C into the microwave reactor, the volume filling degree is 50%, then seal the reactor, put it into the microwave hydrothermal reactor, select the temperature control mode to react, and the temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com