Evaporation crucible and evaporation device

A crucible and evaporation technology is applied in the field of display device production, which can solve the problems affecting device performance, denaturation, low thermal conductivity, etc., and achieve the effects of improving heating uniformity, evaporation rate uniformity, and film layer distribution uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

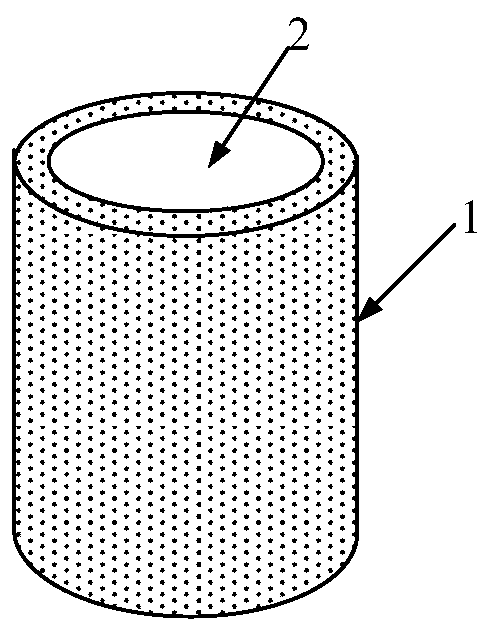

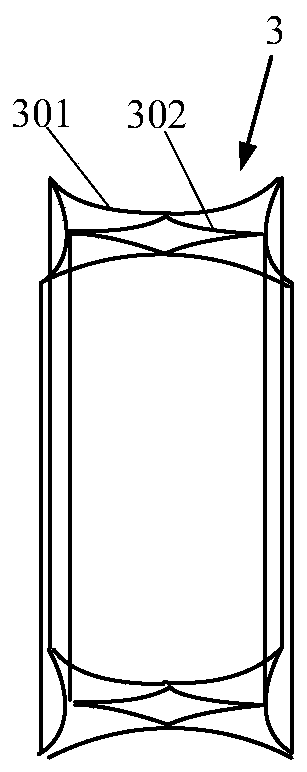

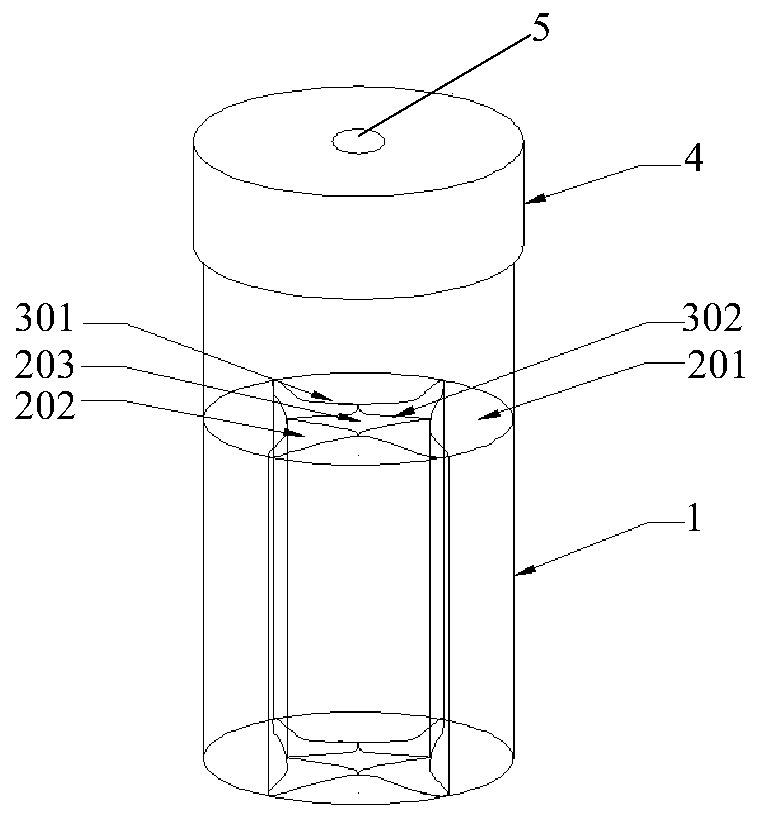

[0028] As the first specific embodiment of the present invention, the structure of the heat conduction structure 3 refers to Figure 2 to Figure 4 As shown in , when the heat conduction structure 3 is arranged in the housing cavity 2, the housing cavity 2 can be divided into a plurality of housing sub-cavities, wherein the axis of the housing cavity 2 passes through one of the housing sub-cavities 203, and the remaining multiple housing sub-cavities 201 and 202 are arranged around the axis of the containing cavity 2, and the opening of each containing sub-cavity 201, 202 and 203 is located at its top. Moreover, the heat conduction spacers 301 and 302 are mesh heat conduction layers, so that the accommodation sub-cavities 201, 202 and 203 can communicate with each other, so that the material to be evaporated can communicate with each other between the accommodation sub-cavities 201, 202 and 203 flow. In the present invention, the accommodating chamber 2 is a cylindrical space,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com