Composite structure of prefabricated bearing concrete wallboard and construction method thereof

A prefabricated concrete and composite structure technology, applied to walls, building components, building structures, etc., can solve the problems of low shear strength, heavy masonry labor, complex procedures, etc., and achieve good earthquake resistance, large bearing capacity, The effect of small pool area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

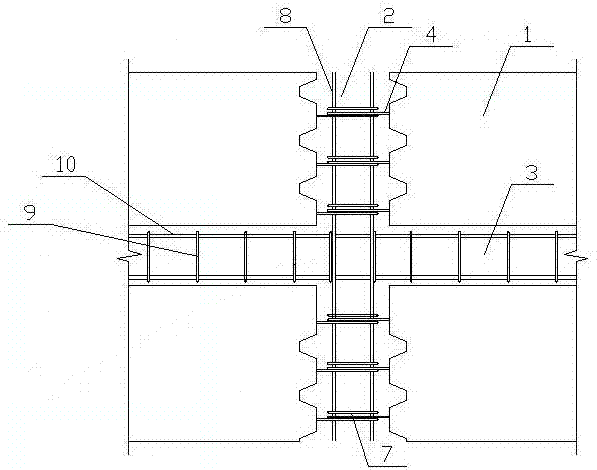

[0033] A prefabricated load-bearing concrete wall panel composite structure is characterized in that: the prefabricated load-bearing concrete wall panel composite structure is mainly composed of a ring beam 3, a prefabricated concrete wall panel 1, and a structural column 2, and the structural column and the described structural column The ring beam is fixedly connected, the prefabricated concrete wall panel is arranged on the surrounding area of the construction column and the ring beam, and the construction column and the ring beam are respectively connected with the precast concrete wall panel , the structural column includes a plurality of structural column stirrups 7, and the corresponding four corners inside the plurality of structural column stirrups are respectively provided with structural column longitudinal bars 8, and the ring beam includes a plurality of rings Beam stirrups 9 , ring beam longitudinal bars 10 are provided at the corresponding four corners inside t...

Embodiment 2

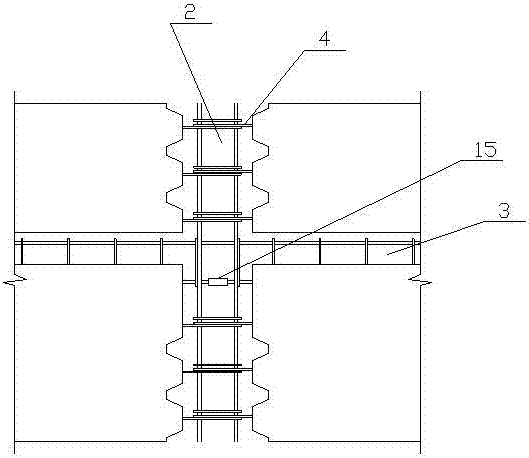

[0035] According to the prefabricated load-bearing concrete wall panel composite structure described in Example 1, both the structural column and the ring beam are cast-in-situ concrete structures, and the outstretched steel bars 4 in the prefabricated concrete wall panel extend into the The inside of the structural column, the structural column is fixedly connected with the ring beam, and the concrete is poured on the structural column and the ring beam to form an integrated structure with the prefabricated concrete wall panel.

Embodiment 3

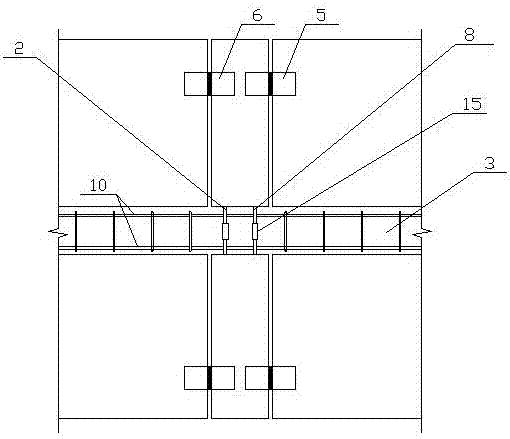

[0037] According to the prefabricated load-bearing concrete wall panel composite structure described in embodiment 1, the described structural column is a prefabricated concrete member, the two described structural columns are connected by sleeves 15, and the described ring beam is a cast-in-situ concrete structure , the connection side of the prefabricated concrete wall panel and the structural column is pre-embedded with a welded connector A, part number: 5, and the upper and lower ends of the two sides of the described structural column are pre-embedded with a welded connector B, part number : 6, the welded connector A is welded with the welded connector B, and the concrete is poured on the ring beam and the prefabricated concrete wall panel forms an integrated structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com