Measurement method of electron microscopic image line width and roughness

A technology of line width and electron microscopy, applied in the direction of electric/magnetic roughness/irregularity measurement, electromagnetic measuring device, measuring device, etc., can solve the problem of only analyzing limited data points and measuring line width and roughness Large volume, measurement error and other problems, to achieve the effect of reducing limitations, reducing the influence of background pixels, and accurate boundary positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

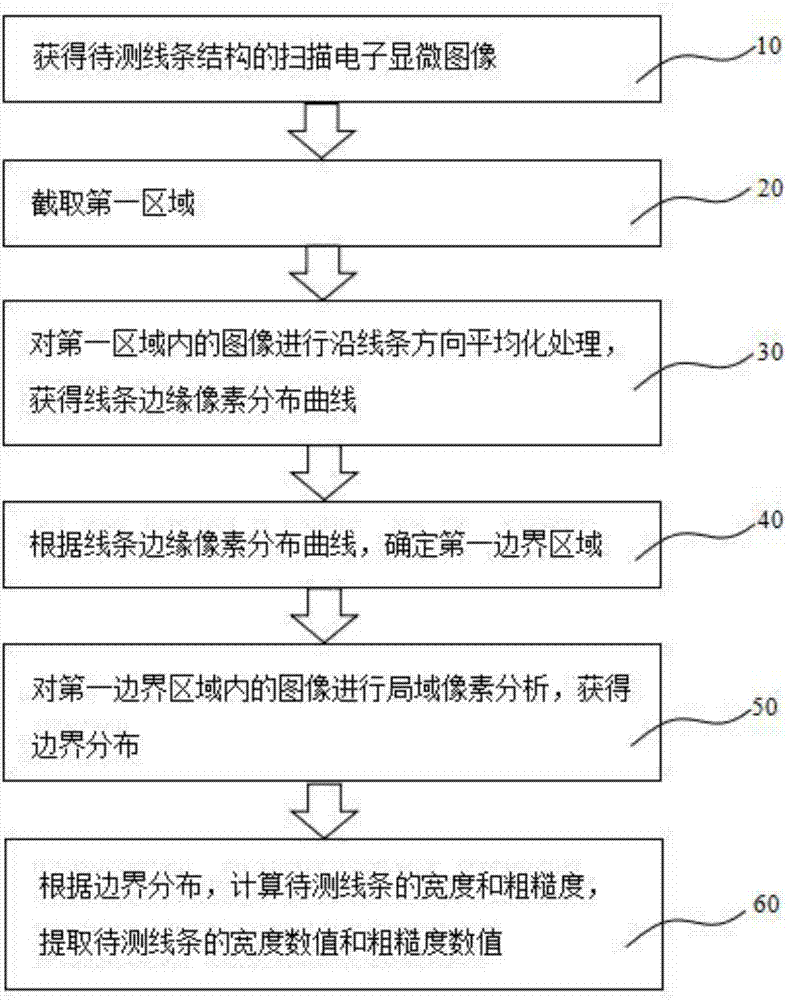

[0049] This embodiment provides a method for measuring line width and roughness of an electron microscopic image, such as figure 1 shown, including:

[0050] Step 10: Obtain a scanning electron microscopic image of the line structure to be tested.

[0051] The line structure to be tested may be a photolithography pattern obtained after a photolithography process. The photolithography process is to form a pattern on the photoresist, and the pattern is further used as a mask layer for etching. The structure of the side lines to be etched can also be obtained by etching the layer to be etched to obtain an intermediate pattern or target pattern, and the layer to be etched can be any required material layer, substrate, dielectric material layer or metal layer, etc. For the material layer to be etched, the etching process can be wet etching or photolithography etching. The line structure to be tested may be a sliced line pattern. The line structure to be measured may also be a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com