Handheld pipeline welding seam flux leakage detection device and detection method thereof

A magnetic flux leakage detection, hand-held technology, applied in the direction of material magnetic variables, etc., to achieve the effect of increasing data amplitude, accurate detection results, and broadening the scope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

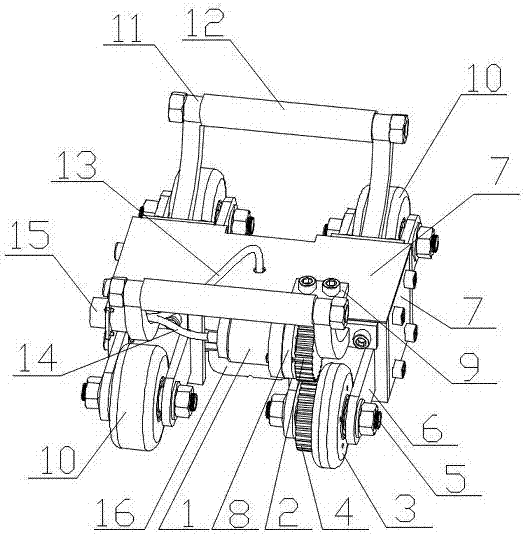

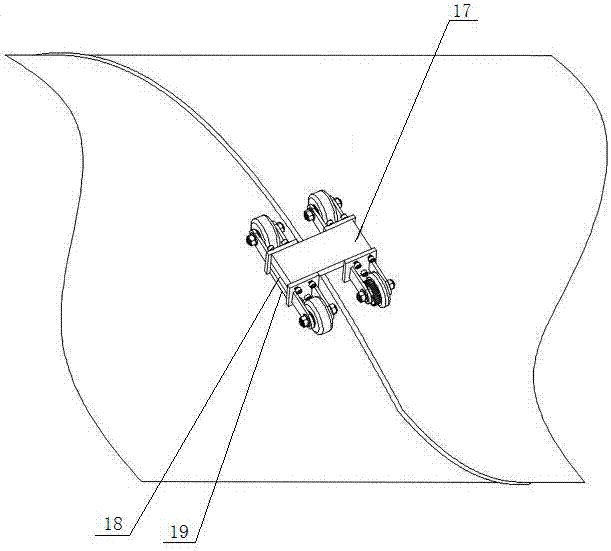

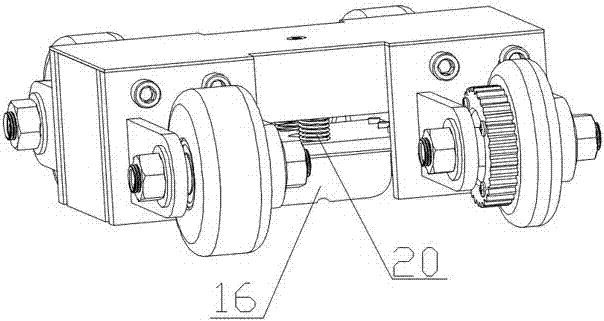

[0025] Below in conjunction with accompanying drawing, the present invention will be further described:

[0026] combine figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, this hand-held pipeline welding seam flux leakage detection device includes a magnetization mechanism, a data acquisition mechanism, and a frame. The front and rear ends of the frame are equipped with traveling wheels 10, and the traveling wheels 10 can be manually driven along the pipeline. The weld seam advances in a straight line at a constant speed. The frame is formed by guard plates 7 installed around and above, and the guard plates 7 play a role in protecting the magnetization device, preventing external collisions from causing damage to the magnetization device. The driving handle is arranged on the front end of the frame, that is, it is installed along the direction of the magnetization mechanism. The driving handle 11 is used to pick and place and carry the present invention on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com