An information management system for photovoltaic power station projects

A technology of information management and engineering projects, applied in the field of photovoltaic power station project management, can solve problems such as prone to omissions and errors, large randomness, and low efficiency, so as to save construction and operation and maintenance costs, realize precise management, and save operation and maintenance costs. Dimension cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

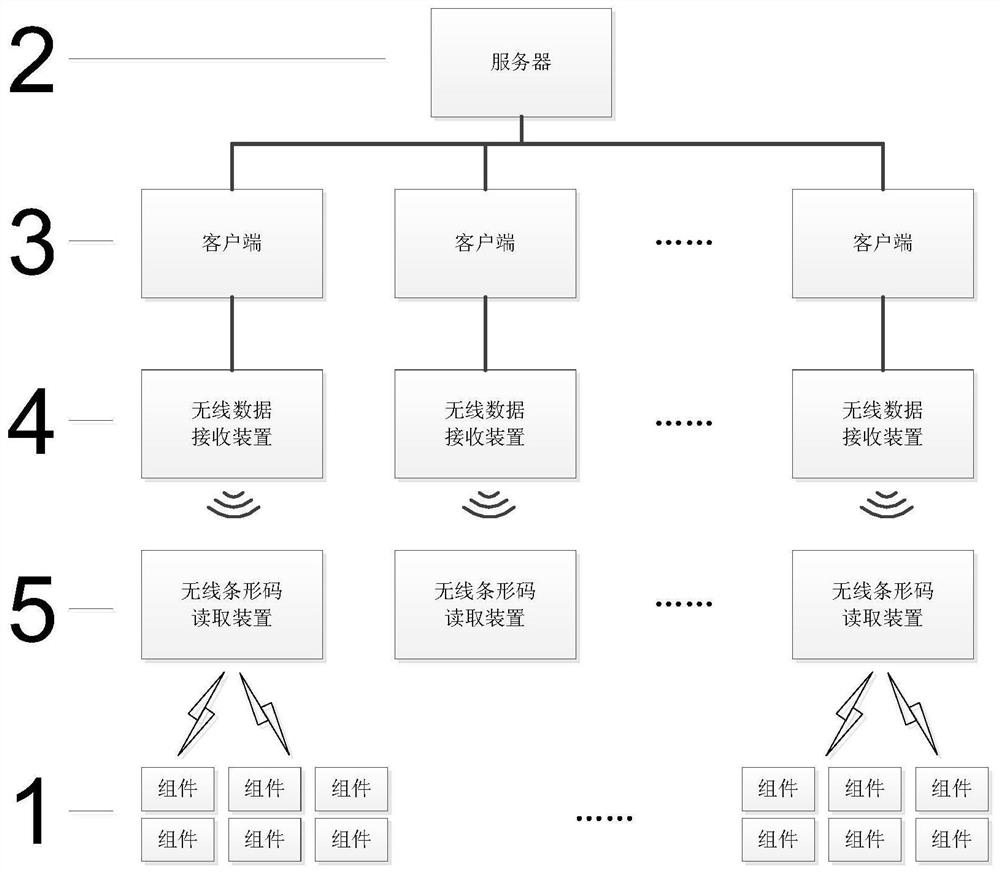

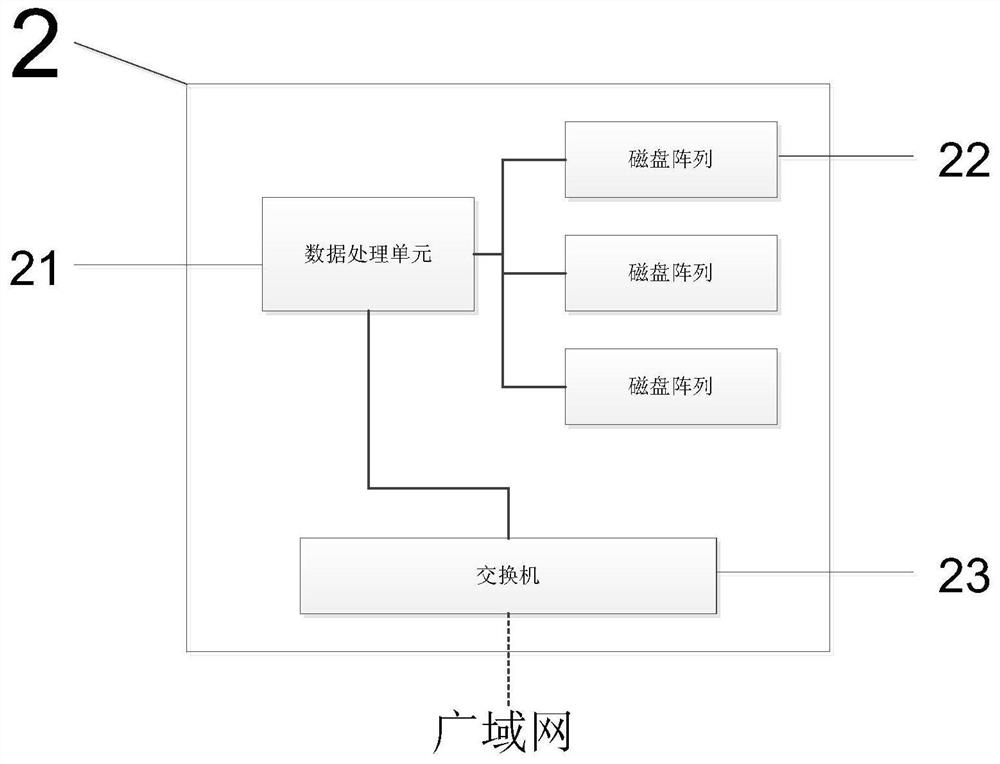

[0023] like figure 1 As shown, the photovoltaic power plant project information management system of the present invention includes a plurality of photovoltaic modules 1 , a server 2 , a client 3 , a wireless data receiving device 4 , and a wireless barcode reading device 5 . in,

[0024] Photovoltaic modules are the smallest units for generating electricity in photovoltaic power plants, and each photovoltaic module is affixed with a barcode.

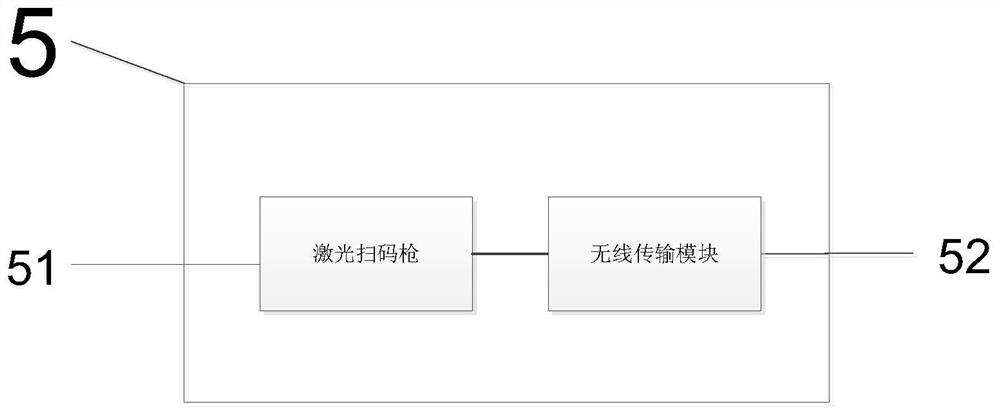

[0025] The wireless barcode reading device 5 reads the barcode of each photovoltaic module, and the wireless data receiving device 4 can receive the scanning information of the photovoltaic module returned by the wireless barcode reading device 5 and transmit it to the client 3 through the USB inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com