Composite potential clamp grading ring for electric reactor

A technology of voltage equalizing rings and reactors, which is applied in the direction of circuits, electrical components, transformer/inductor parts, etc., can solve the problems of increased manufacturing difficulty, increased temperature rise limit, and high cost, so as to achieve convenient processing and ensure overall Simple and reliable performance and structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

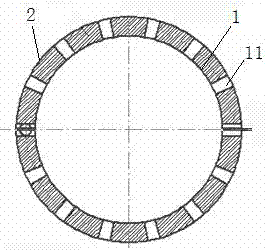

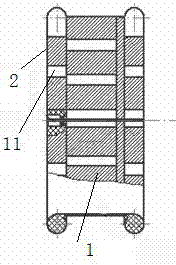

[0012] The invention includes a frame 1 formed by winding epoxy glass filaments, and a semiconductor layer 2 is arranged on the outer surface of the frame 1 .

[0013] The skeleton 1 is provided with cooling holes 11 in the radial direction, and several of the cooling holes 11 are evenly distributed in the circumferential direction of the skeleton 1 .

[0014] The width of the cooling holes 11 is 5-10 cm.

[0015] The width of the cooling hole 11 is 8cm.

[0016] The present invention adopts the whole winding of epoxy glass filament, winds the blank on the numerical control bed once, and then carries out fine turning molding to form the pressure equalizing ring skeleton 1 . Then, a semiconductor layer 2 is formed by attaching a semiconductor material to the surface of the framework 1, so that it has the function of conductivity and uniform high-voltage electric field.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com