Structure capable of improving light transmission efficiency and distribution uniformity of xenon lamp

A technology of distribution uniformity and transfer efficiency, applied in lasers, laser parts, electrical components, etc., can solve the problems of insufficient understanding of the xenon lamp luminous model, difficulty in uniform distribution of xenon lamp intensity, waste of xenon lamp radiation energy, etc. Efficiency, reduced energy supply, compact design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

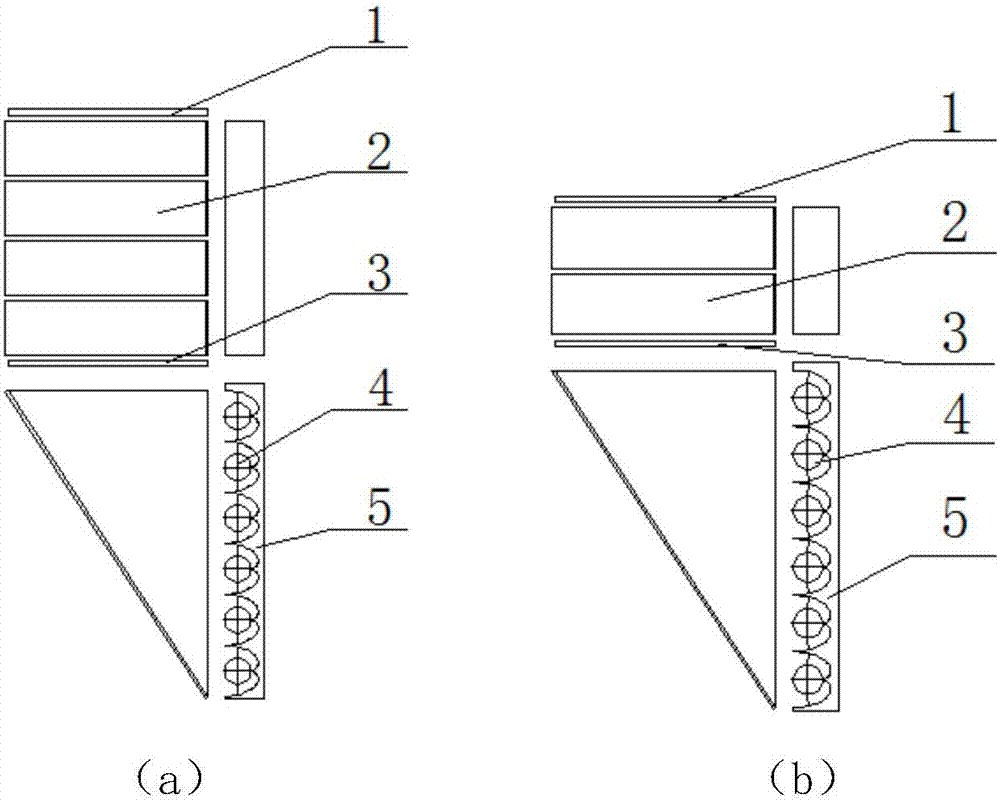

[0021] The schematic diagram of the xenon lamp pumping structure of the original chip amplifier is shown in figure 1 , consisting of a xenon lamp 4, an imitation involute reflector 5, a gain medium 2, upper and lower reflectors 1 and 3, the xenon lamp 4 is a pump source composed of countless point light sources on the outer surface, and the back of the xenon lamp 4 is used to imitate an involute The reflector 5 reflects the light in the two-dimensional plane facing away from the surface of the gain medium 2 without absorption (or a small amount of absorption) once or multiple times, and uses the upper and lower reflectors 1 and 3 to emit the xenon lamp 4 to the outside of the surface of the gain medium 2 Part of the light is reflected one or more times to the surface of the gain medium 2, wherein the gain medium 2 is placed at Brewster's angle.

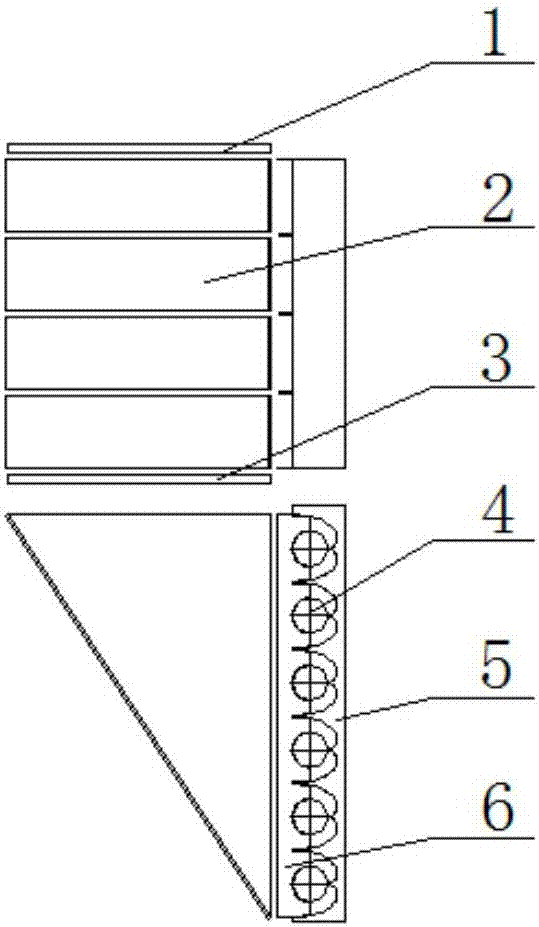

[0022] see first figure 2 , figure 2 It is a structural schematic diagram of Embodiment 1 of the method of the present invention...

Embodiment 2

[0025] The xenon lamp 1 pumping structure of the original chip amplifier is as figure 1 (b), see Example 1.

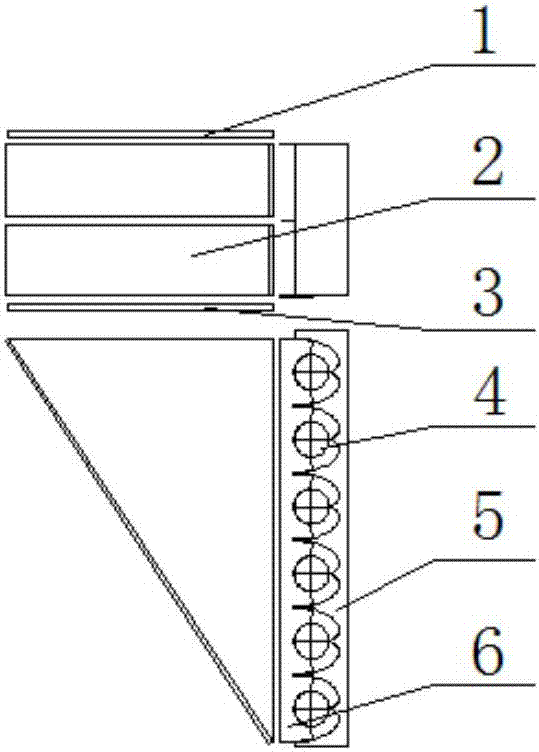

[0026] see first image 3 , image 3 It is a schematic diagram of the structure of Embodiment 2 of the method of the present invention. It can be seen from the figure that the structure of the present invention improves the transmission efficiency and distribution uniformity of xenon light. The plate 1 and the lower reflector 3 are characterized in that a reflective sheet 6 is added between the xenon lamp 4 and the reflector 5 along the cross-sectional direction of the xenon lamp 4, and the reflective sheet 6 is arranged along the axial direction of the xenon lamp 4, and the reflective sheet The number of 6 N=3, the thickness d of the reflective sheet 6 1 =2mm, the distance d between the reflector 6 and the gain medium 2 2 = 10 mm, the reflectors are 6 planar sheets arranged at equal intervals along the axial direction of the xenon lamp 4 .

[0027] Use TracePro.E...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap