Geotechnical centrifuge model testing equipment and excavation simulation method

A technology of model testing and geotechnical centrifugation, which is applied in basic structure testing, basic structure engineering, construction, etc., can solve problems such as unfavorable safe operation of centrifuges, difficulty in reflecting real working conditions, and complicated excavation soil operations, etc., to achieve convenience Effective simulation, convenient model making, and the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

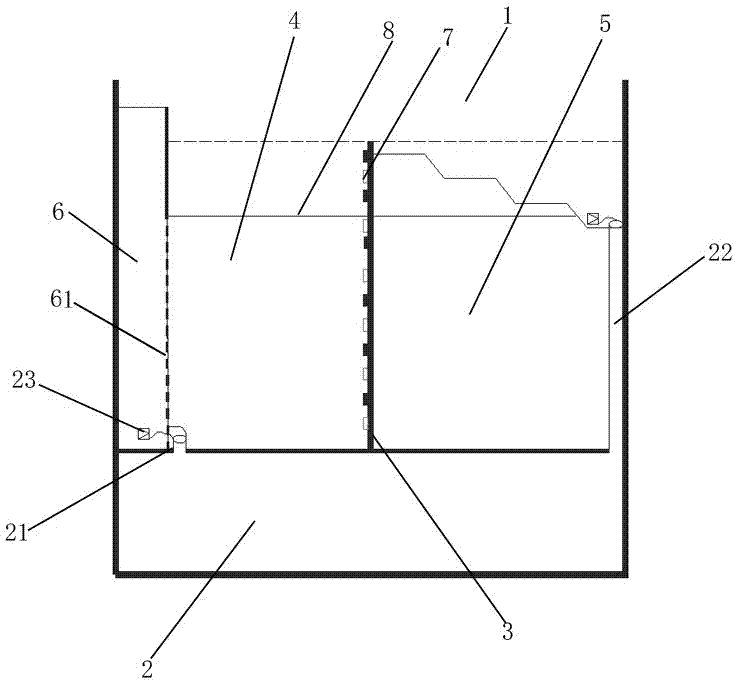

[0028] A kind of geotechnical centrifugal model test equipment, including a model box 1, the bottom of the model box is provided with a water storage tank 2, and the middle and upper part is located on the water storage tank to separate the foundation pit cavity 5 and fill with The soil filling cavity 4 of the soil material is provided with a water level water tank 6 connected to the water storage tank through a conduit 21 to control the water level of the filling cavity. The gaps are connected through dense seepage holes 61, and the foundation pit cavity is connected to the water storage tank through a conduit 22. The strain gauge of the internal force that the plate bears and the earth pressure sensor 7 of the change of lateral earth pressure.

[0029] The foundation pit cavity and the filling cavity are arranged adjacently, and the water level water tank is arranged on the wall of the water storage tank on the side of the filling cavity facing away from the foundation cavit...

Embodiment 2

[0043] The difference from the above-mentioned embodiment is that the filling cavity is set outside the foundation pit cavity, and the water level water tank is set against the outer wall of the filling cavity or inserted in the filling cavity, and inserted in the filling cavity. Water seepage holes are arranged on the wall circumference of the water level water tank in the soil cavity.

Embodiment 3

[0045] The difference from the above embodiment is that the water storage tank includes two chambers respectively connected to the water level water tank and the foundation pit cavity, and the conduit 1 and conduit 2 are each connected with a suction pump. When the liquid suction pump is set on the conduit one and the conduit two, the filling liquid in the step one and the water level water tank injection in the step three can be pumped from the two chambers to the excavation area and the water level water tank respectively by the liquid suction pump. Thus, the setting of the liquid supply system can be omitted. The two chambers of the liquid storage tank respectively store water and liquids with a density similar to that of the soil, and are recyclable and recycled for many times. Repeated tests are also carried out continuously to obtain multiple sets of data, and the experimental results are more accurate.

[0046] Compared with the existing simulation technology of foundat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com