a grain dryer

A grain dryer and drying machine technology, applied in the direction of dryer, drying, grain drying, etc., can solve the constraints that are easily affected by weather and site, natural drying cannot meet the demand, and grain drying is uneven Incomplete and other problems, to achieve the effect of preventing secondary drying, high work efficiency, and good quality of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The embodiment given below intends to further illustrate the present invention, but can not be interpreted as the restriction to protection scope of the present invention, those skilled in the art still belongs to the protection of the present invention to some non-essential improvements and adjustments of the present invention according to the content of the present invention scope.

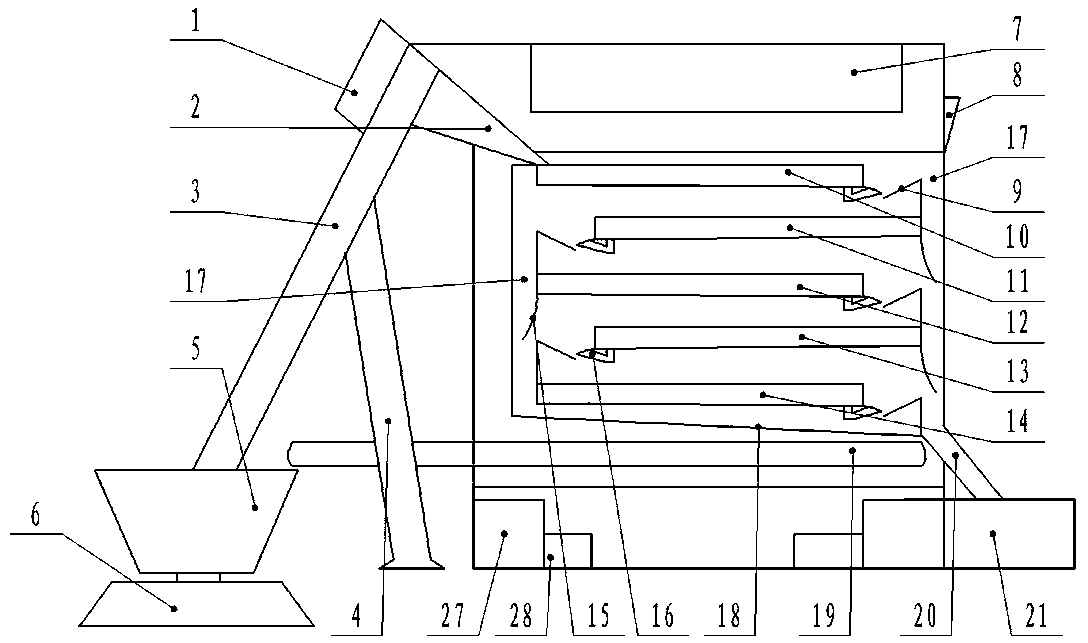

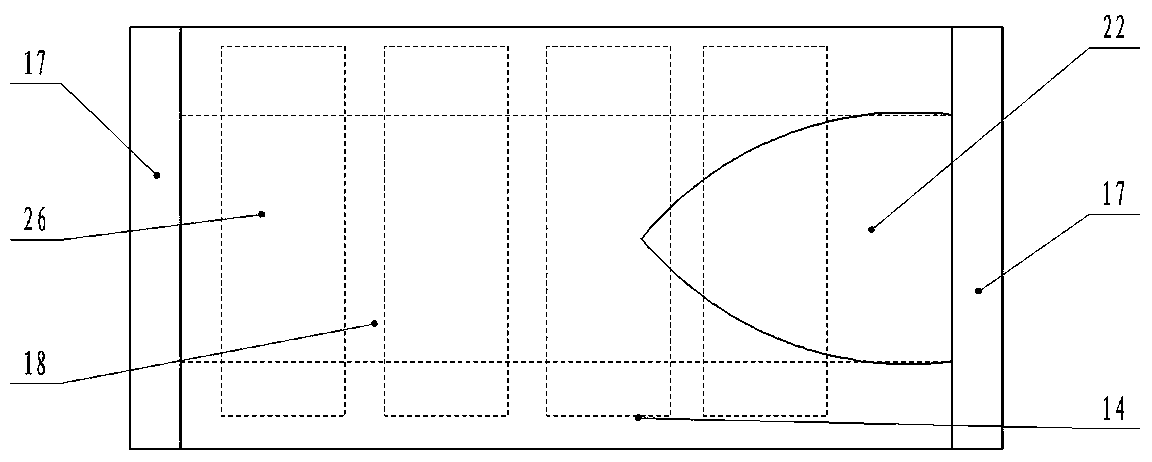

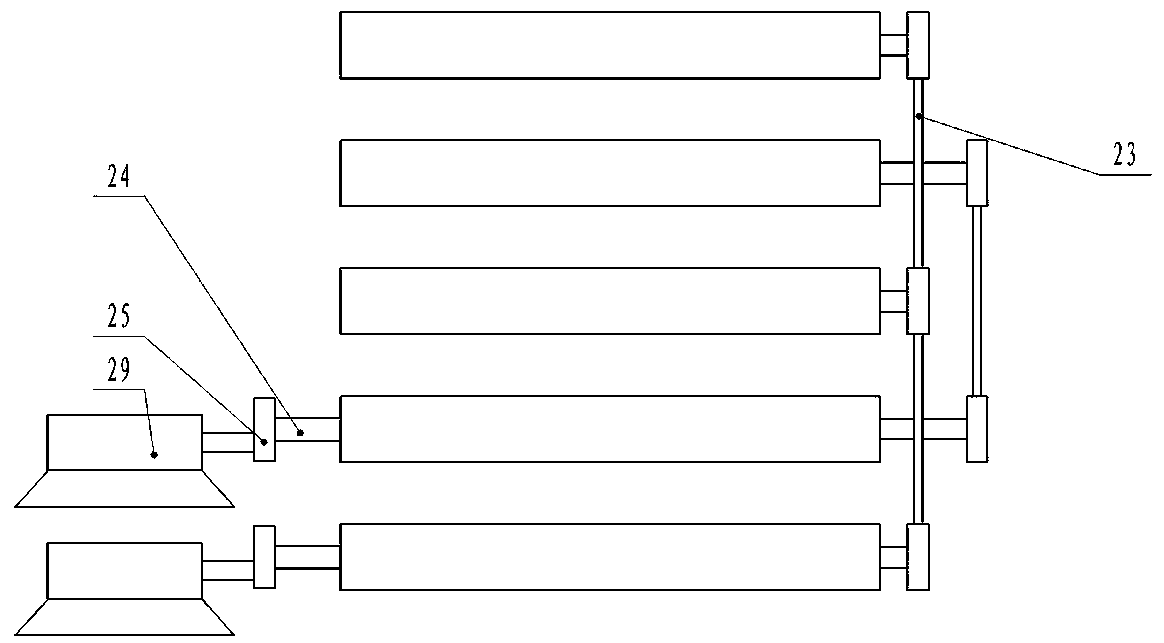

[0023] exist figure 1 , 2 , 3, 1. Feeding machine motor, 2. Feeding port, 3. Feeding machine, 4. Feeding machine bracket, 5. Grain storage bin, 6. Base, 7. Dehumidifier, 8. Exhaust valve , 9. Blocking plate, 10. The first drying plate, 11. The second drying plate, 12. The third drying plate, 13. The fourth drying plate, 14. The fifth drying plate, 15. Arc Shaped baffle plate, 16. Fan, 17. Dry material feeding bin 1, 18, Dry material feeding bin 2, 19. Conveyor belt, 20. Outlet, 21. Collecting bin, 22. Splitter plate, 23. Connecting rod, 24. connecting shaft, 25. eccentric wheel, 26. sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com