Automatic dross scraping machine for molten aluminum

A slag scraper, automatic technology, applied in mechanical cleaning, manufacturing tools, metal processing equipment, etc., can solve problems such as danger, achieve the effect of beautiful appearance, improve slag scraping efficiency, and improve casting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical means, technical features, invention objectives and technical effects realized by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

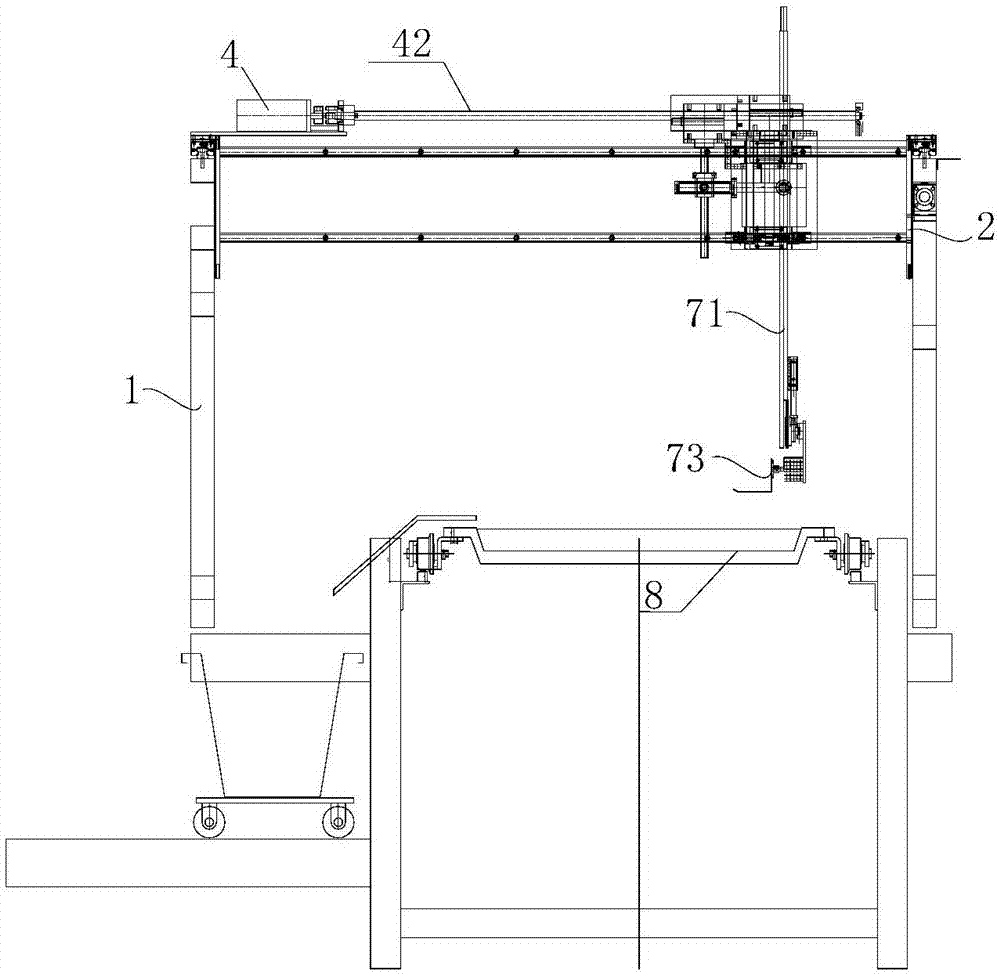

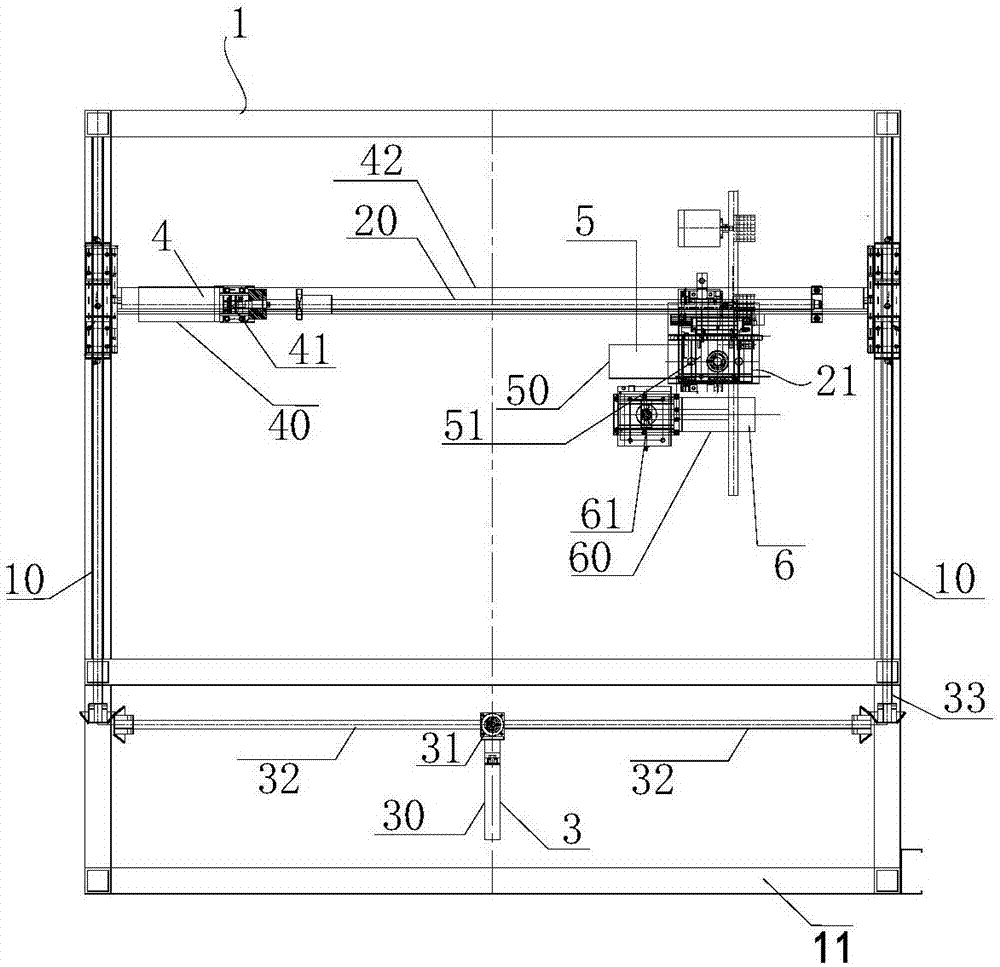

[0024] Such as Figure 1 to Figure 3 As shown, it is an automatic slag scraper for aluminum liquid of the present invention, including a frame 1, an installation box 2, a servo synchronization system 3, a servo left and right operation system 4, a servo scraper up and down operation system 5, and a servo scraper tilting system 6 , and the slag scraping device 7.

[0025] The frame 1 among the present invention is used to set up on the top of the mold 8 of the casting machine, and a pair of first slide rails 10 are arranged symmetrically on the inside of the frame 1, and the two ends of the installation box 2 are arranged on the first rails 10 by slide blocks. The upper part of the slide rail 10 enables the installation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com