Transportation box

A box and pallet technology, used in transportation and packaging, containers, packaging recycling, etc., can solve the problem that wooden boxes are flammable and not moisture-proof, wooden boxes have no buffer function, and wooden boxes have insufficient bearing capacity (bending resistance and impact resistance). problem, to achieve the effect of convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

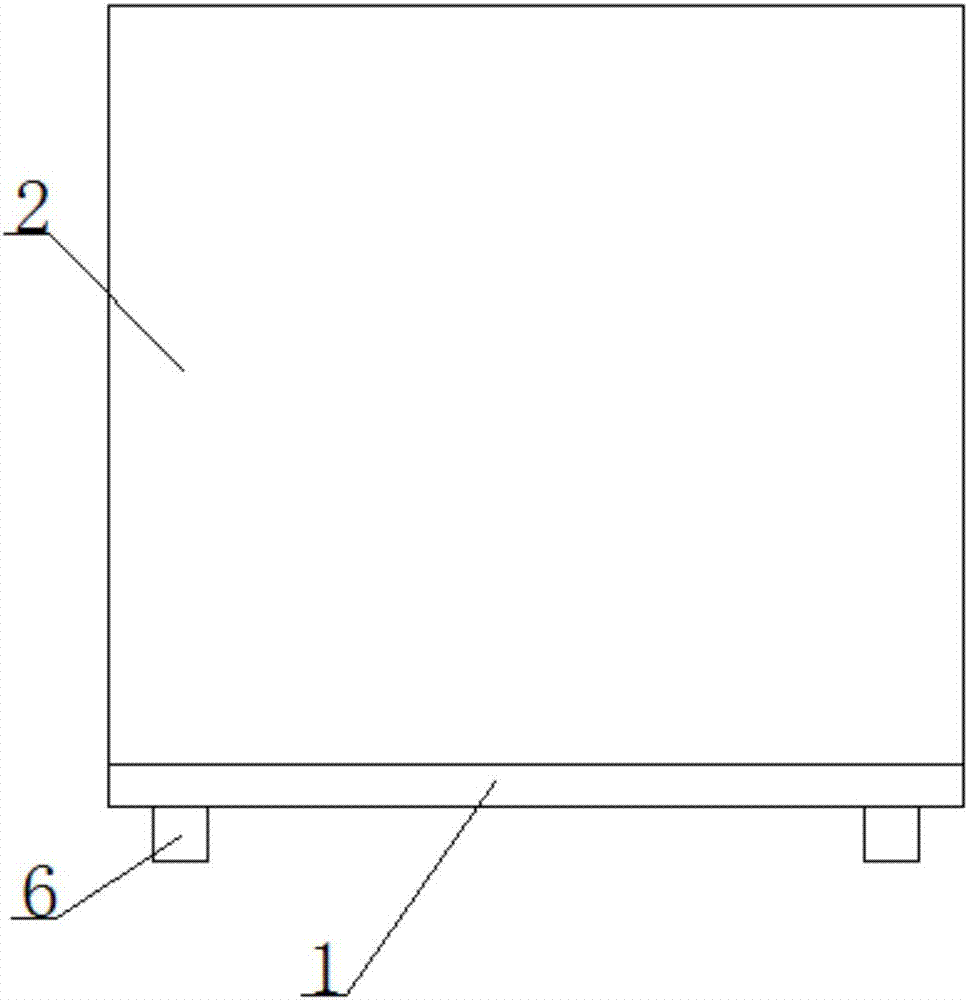

[0045] Such as figure 1 with figure 2 As shown, what needs to be explained here is that the orientation words left and right described in Embodiment 1 are all based on figure 1 The views shown are defined by reference, and it should be understood that the use of the orientation words is only for the convenience of description, and should not limit the scope of protection claimed by the present application.

[0046] A transport box of this embodiment is characterized in that it comprises: a tray 1, a box body 2 and a support leg 6, the support leg 6 is fixed to the bottom of the tray 1, and the tray 1 and the box body 2 are composed of Made of plastic wood material.

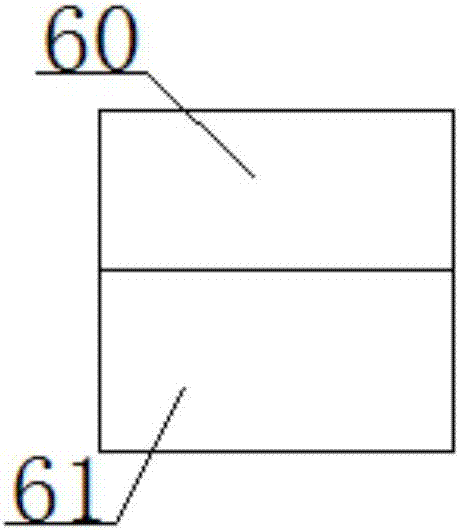

[0047] Preferably, the support leg 6 is composed of a buffer part 60 and a rigid part 61, the buffer part 60 is made of EPO and / or EPP, the rigid part 61 is made of plastic wood material, and the buffer part 60 is solid Connected to the bottom of the tray 1 , the rigid part 61 is fixed to the bottom of the buf...

Embodiment 2

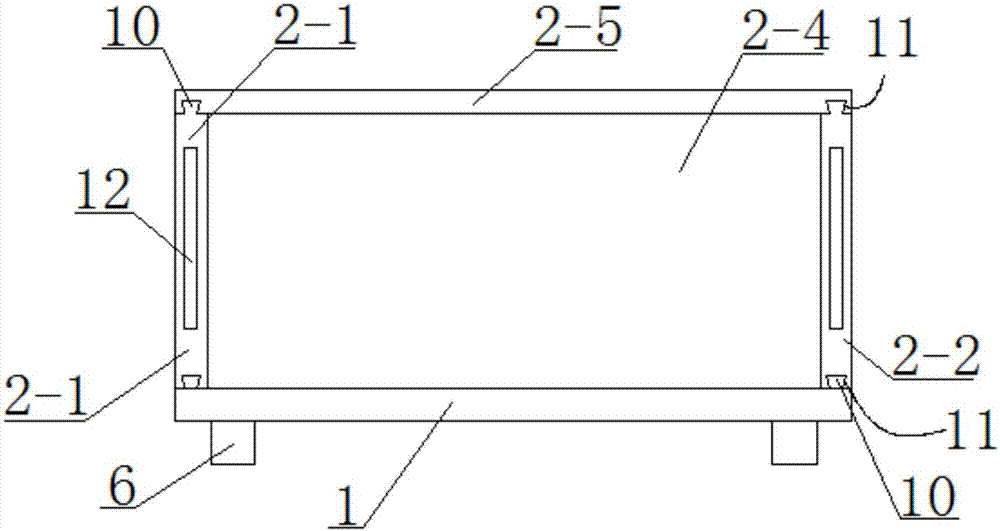

[0066] Such as Figure 3 to Figure 7 As shown, what needs to be explained here is that the orientation words left, right, front, back, up, down, top, and bottom described in Embodiment 2 are all based on image 3 The views shown are defined by reference, and it should be understood that the use of the orientation words is only for convenience of description, and should not limit the scope of protection claimed by the present application.

[0067] A transport box of this embodiment is characterized in that it comprises: a tray 1, a box body 2 and a support leg 6, the support leg 6 is fixed to the bottom of the tray 1, and the tray 1 and the box body 2 are composed of Made of plastic wood material.

[0068] The wood-plastic material is produced and processed from raw materials with the following weight ratio:

[0069] Maleic anhydride grafted polypropylene: 60 parts;

[0070] Wood powder: 70 parts;

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com