Bobbin winder with winding displacement function

A technology of winding device and function, which is applied in the field of winding device with the function of arranging cables, can solve the problems of cable falling off, unfavorable transportation of winding devices, and inability to distribute cables, so as to facilitate transportation, improve the efficiency of winding up, and simplify the The effect of driving the junction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

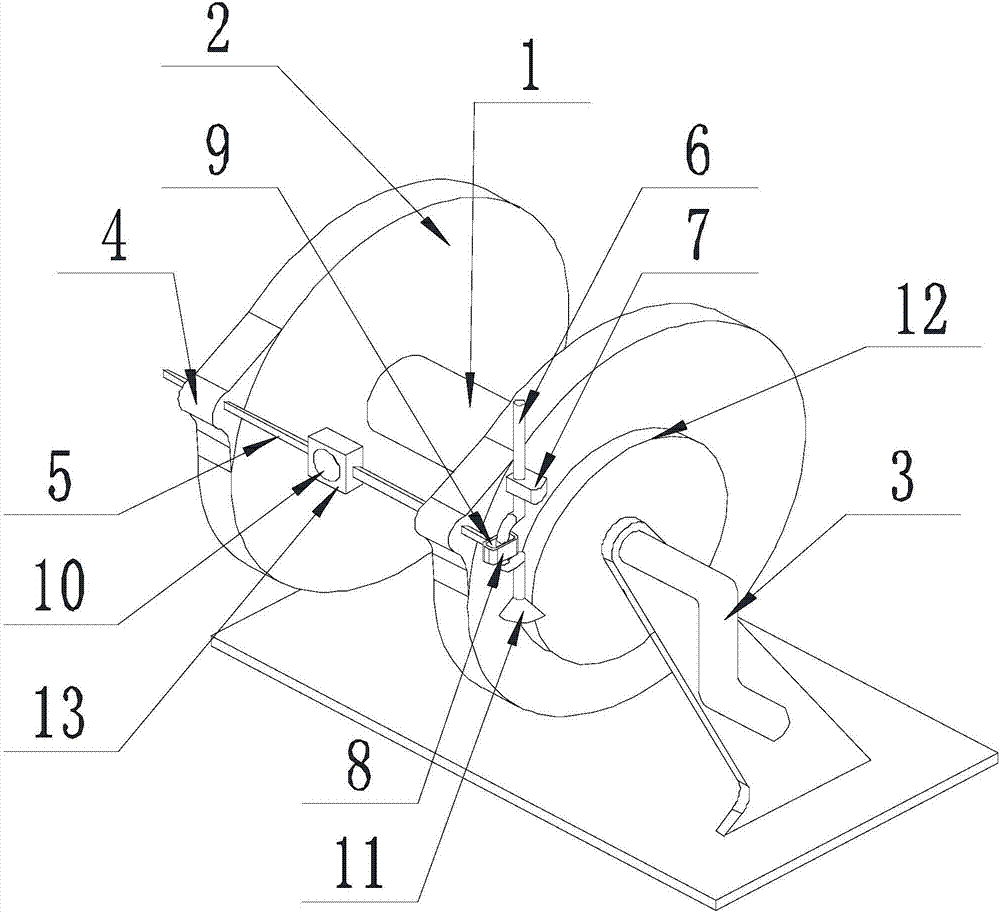

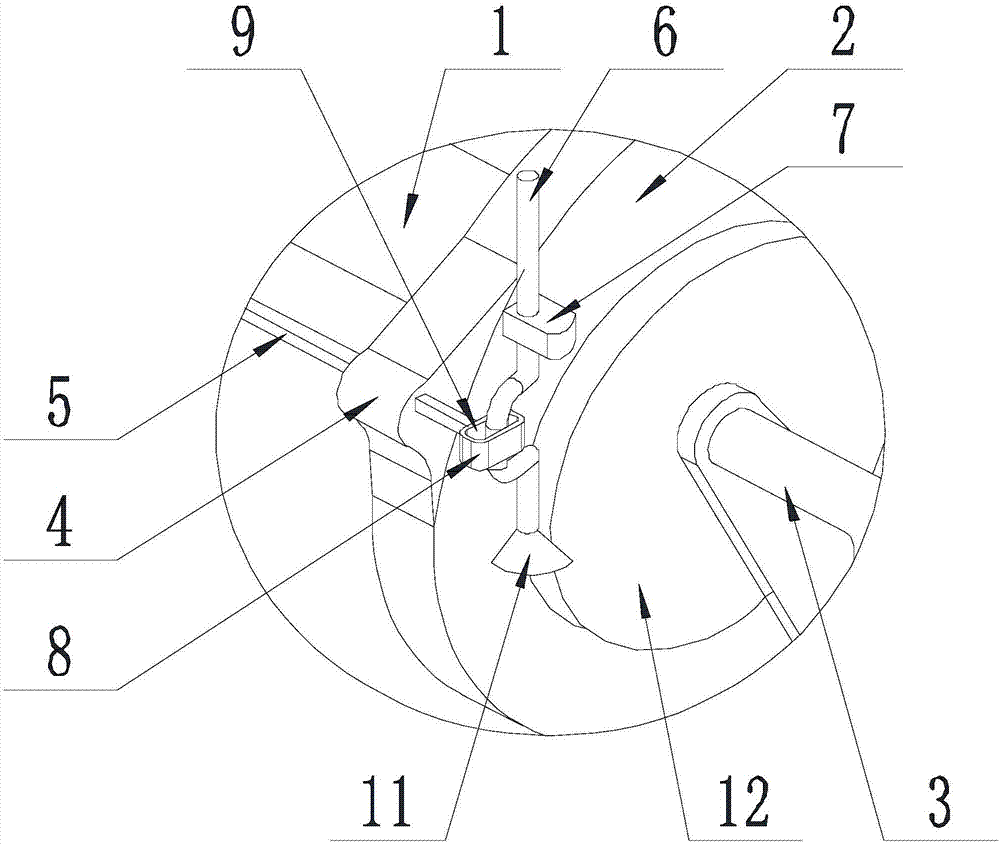

[0028] Such as Figure 1-Figure 3 As shown, the present invention has a wire winder with a wire arrangement function, including a wire winding device body and a wire arrangement assembly, and the wire winding device body is mainly composed of a winding shaft 2, a handle 3, a support assembly and two wire retaining discs 1, One end of the winding shaft 2 is rotationally connected to a wire retaining reel 1, and the other end of the bobbin 2 moves through another wire retaining reel 1 and is connected to the handle 3. The sides of the disk 1 are provided with lugs 4, and the lugs 4 are provided with matching holes, and the axis of the matching holes is parallel to the axis of the winding shaft 2;

[0029] The cable assembly is connected to the wire retaining disk 1, and the cable assembly includes a moving rod 5, a crankshaft 6, a connecting block 7, a fixed block 8 and a driving assembly, one end of the moving rod 5 is located in a matching hole, and the moving rod 5 The other...

Embodiment 2

[0034] The present invention is based on embodiment 1, and the present invention is further described.

[0035] Such as Figure 1-Figure 3 As shown, the present invention has a cable winding function, the drive assembly includes a bevel gear I11 and a bevel gear II12 that mesh with each other, the bevel gear I11 is located on the end of the crankshaft 6 away from the connecting block 7, and the crankshaft 6 The rotation axis coincides with the axis of the bevel gear I11, and the bevel gear II12 is sheathed on the moving rod 5, and the turning handle 3 can drive the bevel gear II12 to rotate.

[0036] Turning the handle 3 during take-up can drive the bevel gear II 12 to rotate, and then impel the moving rod 5 to reciprocate along its own axis, and at the same time rotate the winding shaft 2 to carry out the winding operation, which simplifies the driving structure.

Embodiment 3

[0038] The present invention is based on embodiment 1, and the present invention is further described.

[0039] Such as Figure 1-Figure 3As shown in the present invention, the cable winder with cable arrangement function is provided with a positioning block 13 on the moving rod 5 , the through hole 10 is located on the positioning block 13 , and the positioning block 13 is detachably connected to the moving rod 5 . The through holes 10 with corresponding apertures can be replaced according to cables of different diameters.

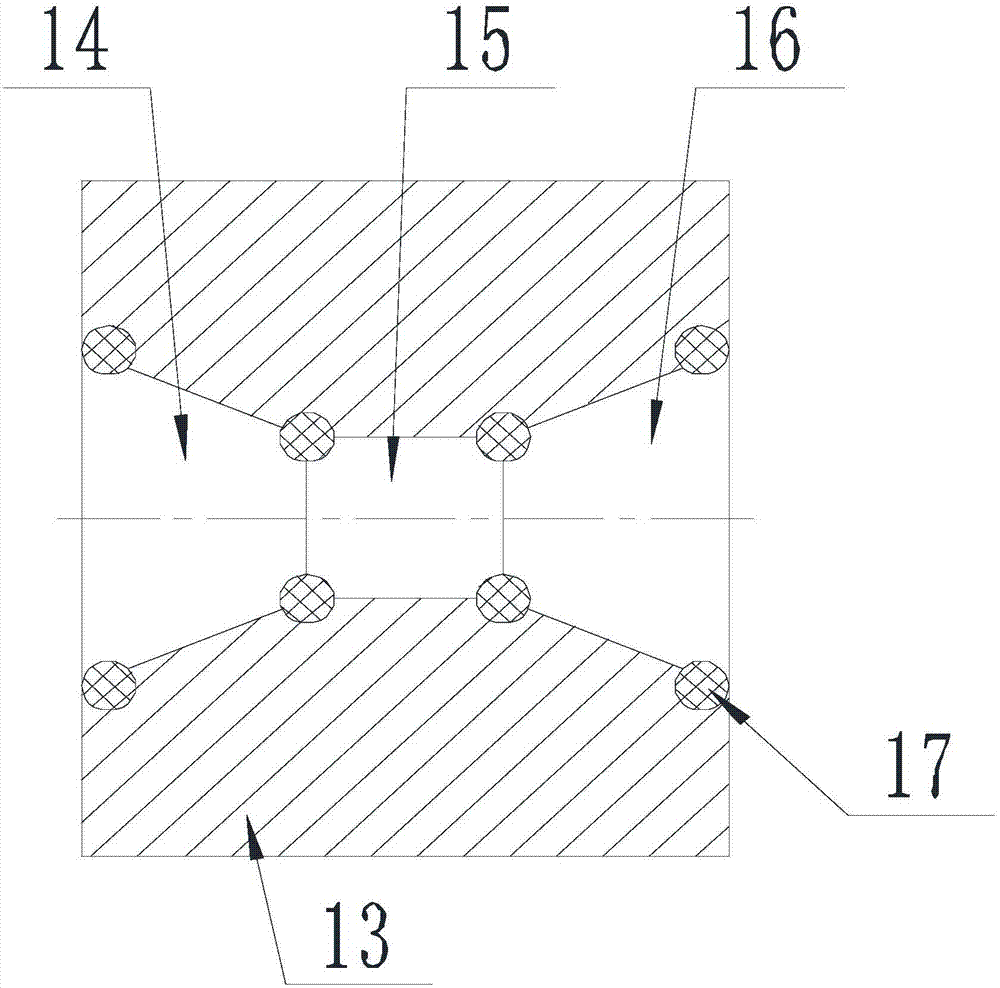

[0040] Further, the through hole 10 includes a first hole 14, a second hole 15 and a third hole 16 which are sequentially connected and coaxial, the diameter of the first hole 14 is a fixed value, and the first hole 14 and the third hole The three holes 16 are tapered holes, and the small-diameter end of the first hole 14 and the small-diameter end of the third hole 16 are respectively connected to two ends of the second hole 15 . The setting of the tap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com