Method and device for growing multilayer heterojunctions through CVD

A technology of heterojunction and growth chamber, applied in coating, metal material coating process, gaseous chemical plating, etc., can solve the problems of difficulty in growing the second layer of heterojunction material, loss of catalytic effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

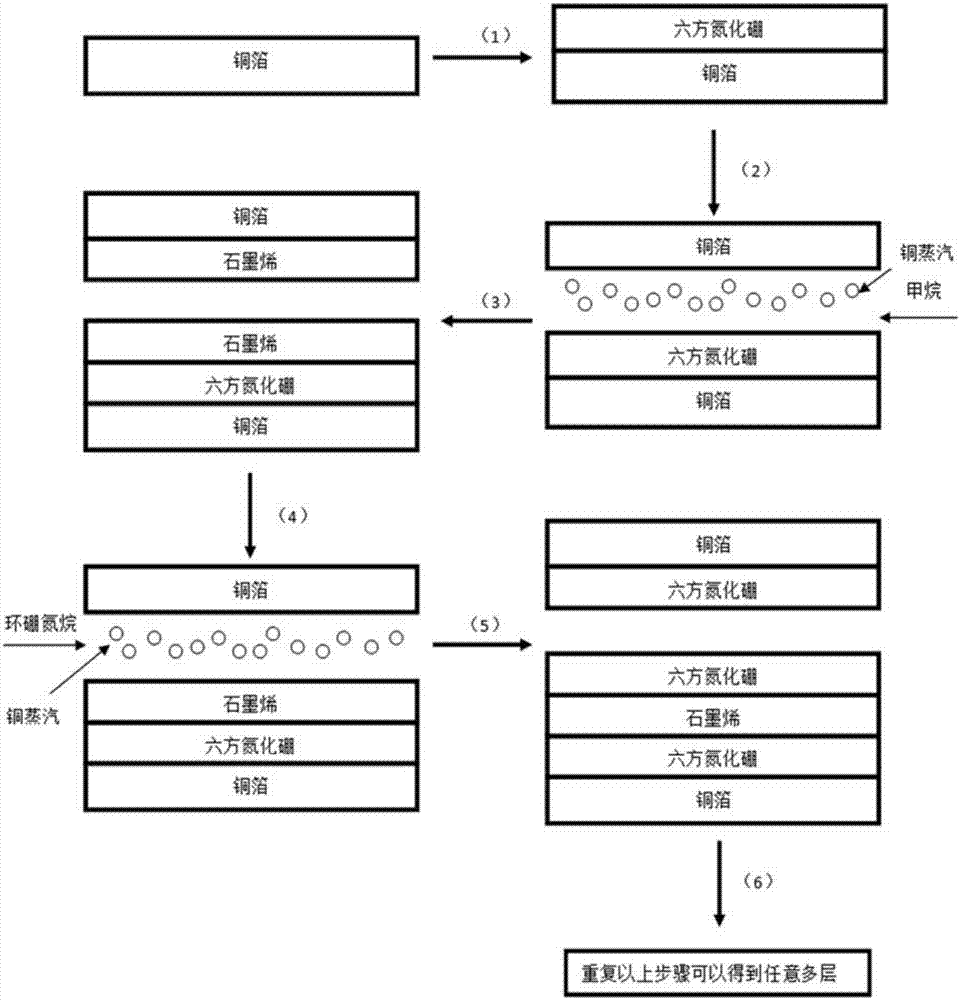

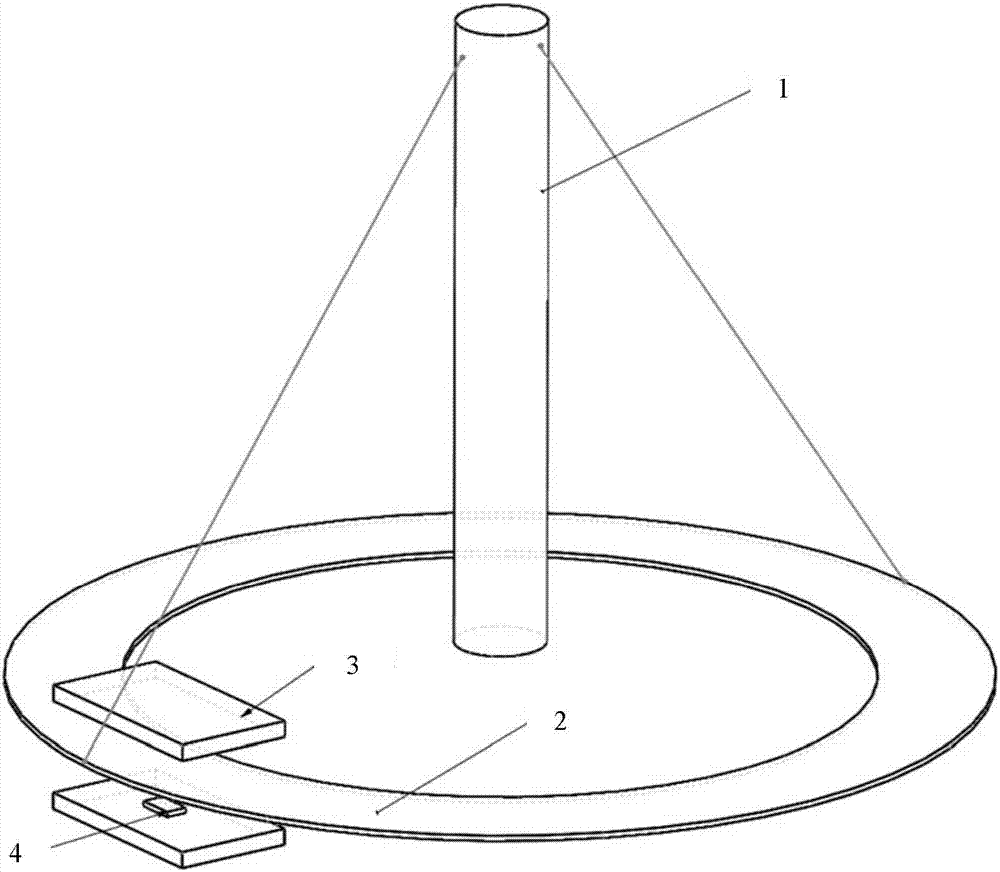

[0046] The flow chart of growing multilayer two-dimensional material heterojunction is attached figure 1 Shown: First, the base copper foil is loaded into the CVD growth chamber, the chamber is evacuated to a high vacuum, and the temperature is raised to a growth temperature of 1000°C. Because the cold wall system is used, the high temperature area will only be limited to a small area. Such a cold wall system has a good effect of suppressing dust pollution. After the temperature is raised to the growth temperature, an annealing process is performed for 2 hours. Then borazine is introduced to grow the first layer of hexagonal boron nitride on the base copper foil, and the growth time is about 40 minutes. When growing the first layer of material, the base copper can completely act as a catalyst, and there is no need to introduce suspended copper foil. After the growth of the first layer is completed, the base copper foil has lost the function of catalyst because it is complet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com