Sandwiched heat preservation L-shaped composite wall body with lead pipe-coarse sand energy-dissipation damping keys and construction method

A composite wall and composite wall panel technology, which is applied in thermal insulation, walls, and earthquake resistance, can solve problems such as slow construction speed, low seismic energy consumption capacity, and poor thermal insulation performance, and achieve high production efficiency, improved thermal insulation effect, and durability good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with specific embodiments.

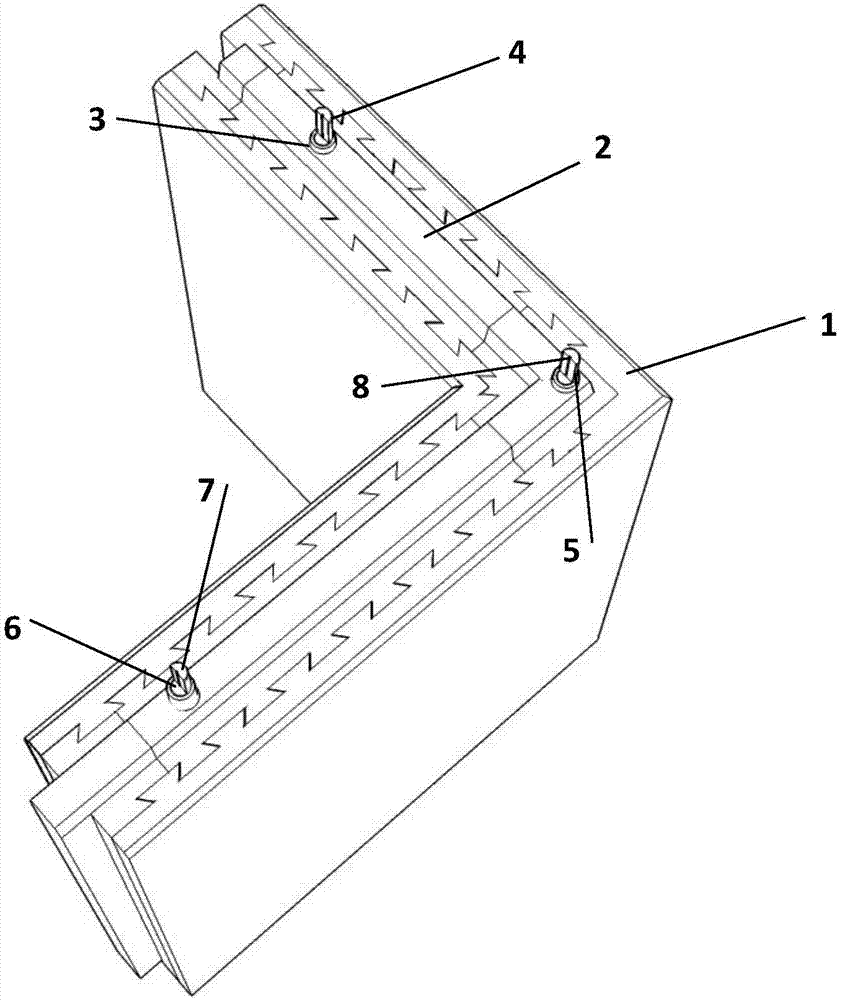

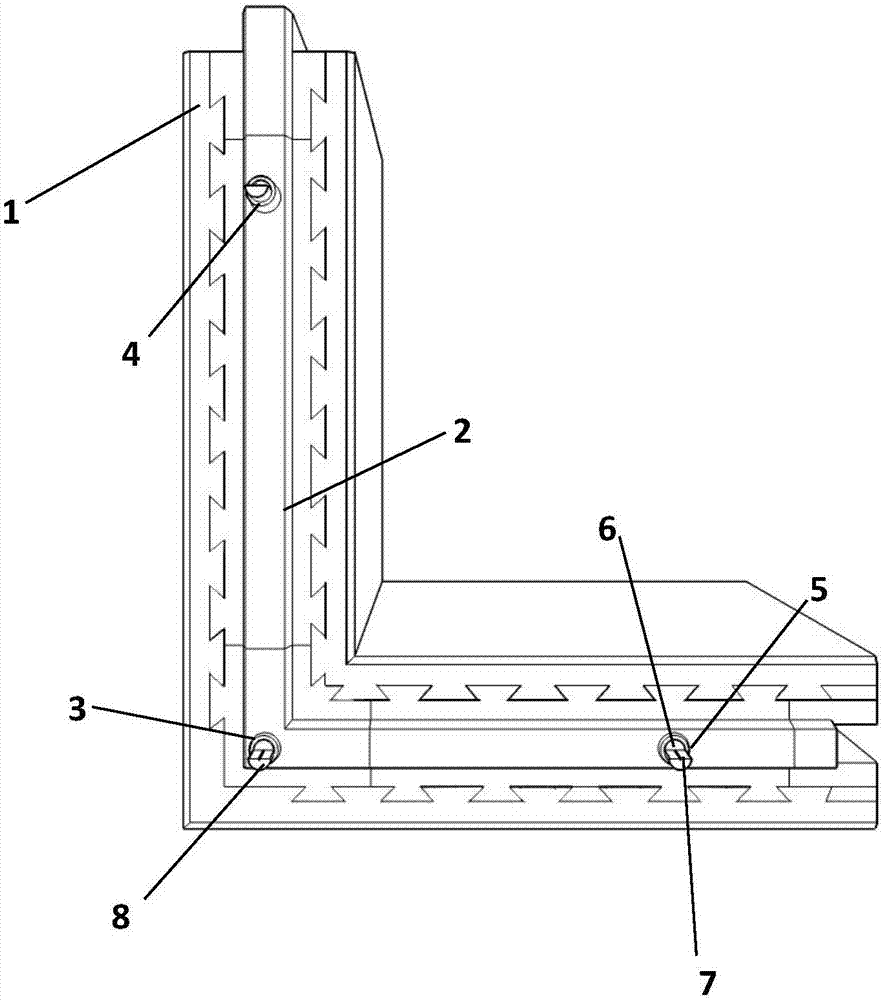

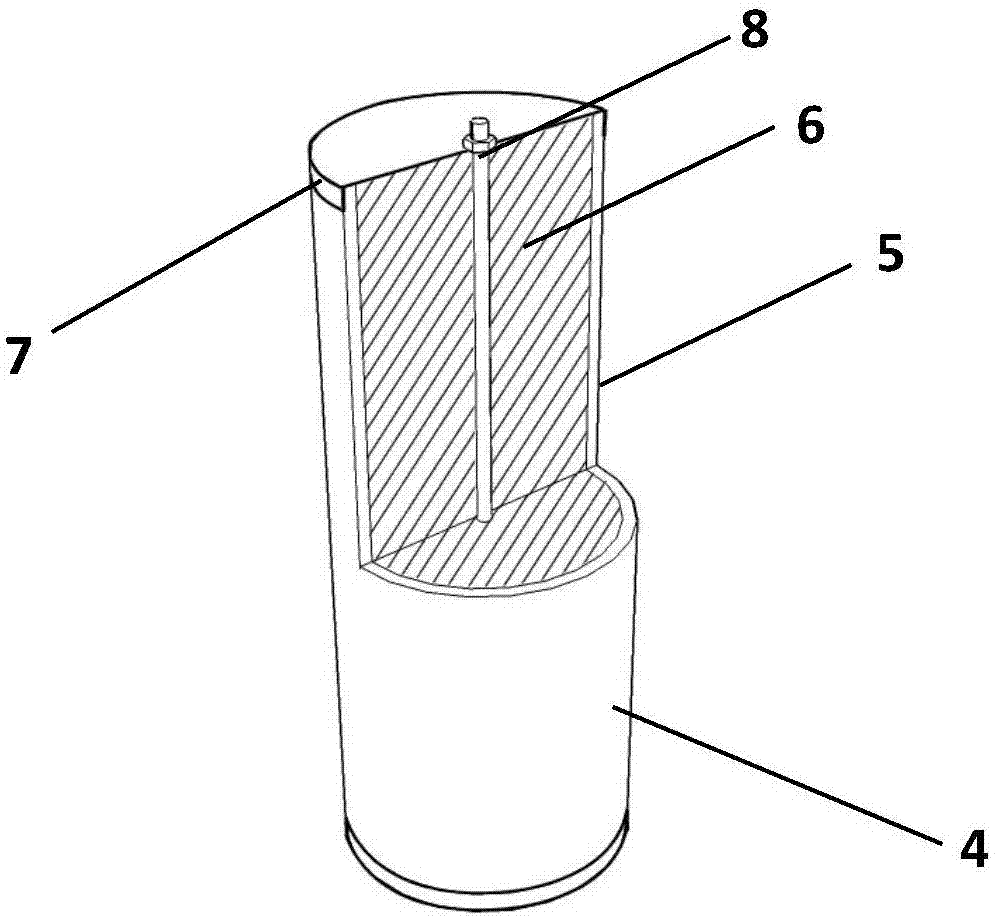

[0041] Such as figure 1 As shown, the sandwich insulation L-shaped composite wall with lead pipe-coarse sand energy-dissipating and shock-absorbing keys of the present invention, the wall structure includes L-shaped recycled concrete wallboard 1, EPS insulation module 2, and winged round pipe fixing parts 3. Lead pipe-coarse sand energy dissipation and shock absorption key 4, lead pipe 5, coarse sand 6, galvanized thin steel sheet cover plate 7 and bolt 8.

[0042] The L-shaped recycled concrete wall panel 1 is composed of recycled concrete and a single row of reinforced steel wire mesh, wherein the diameter of the recycled concrete coarse aggregate particle is 5mm-10mm; the specification of the L-shaped recycled concrete wall panel 1: the length is 600mm-6000mm, The length modulus is 300mm; the section height is 300mm-1500mm, and the height modulus is 100mm; the thickness...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com