Method and system for deep integration and real-time compensation of micro-inertial measurement information

A technology of micro-inertial measurement and real-time compensation, applied in the field of signal processing, can solve the problems of low precision of micro-inertial measurement, error fusion and compensation, increase of fusion deviation, etc., and achieve the effect of improving estimation accuracy, improving accuracy and fast response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

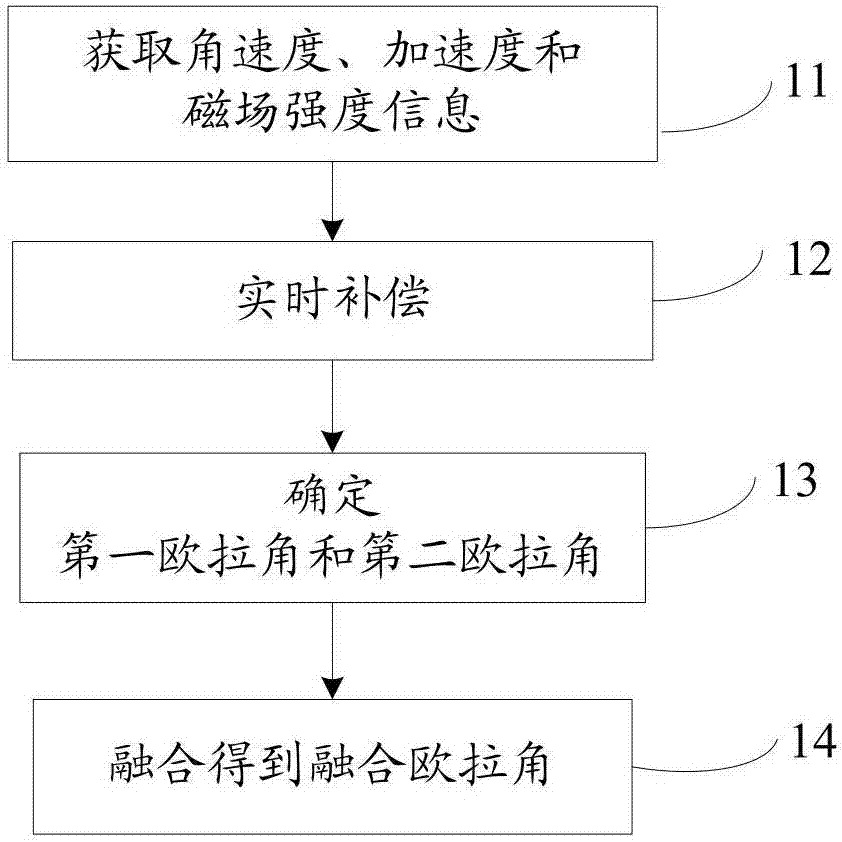

[0050] Such as figure 1 As shown, the deep fusion and real-time compensation methods of micro-inertial measurement information include:

[0051] Step 11: Obtain the angular velocity information, acceleration information and magnetic field strength information of the research object respectively. In this embodiment, the angular velocity information of the research object is measured by a three-axis gyroscope, the acceleration information of the research object is measured by a three-axis accelerometer, and the three-axis The magnetometer measures the magnetic field strength information of the research object;

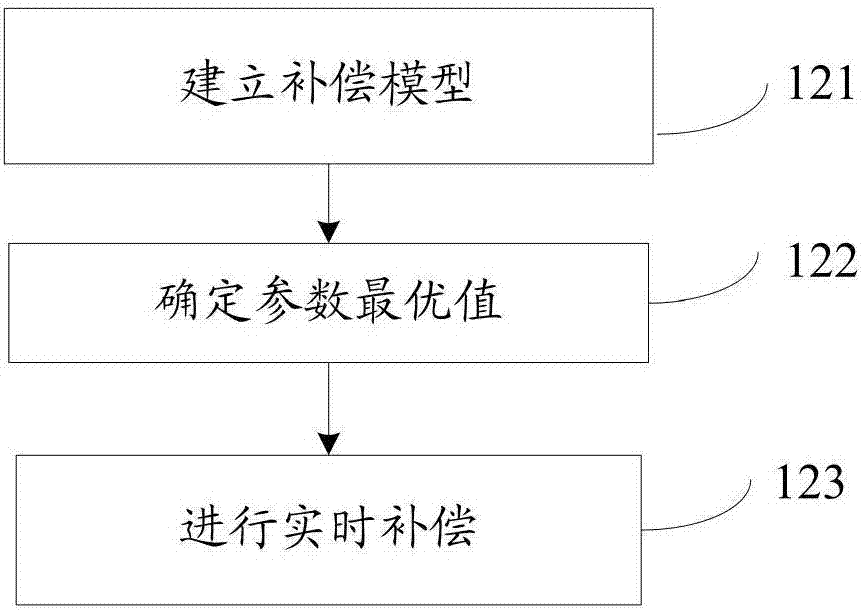

[0052] Step 12: Using the deep learning method to perform real-time compensation on the angular velocity information, acceleration information and magnetic field strength information respectively, and obtain the compensated angular velocity information, the compensated acceleration information and the compensated magnetic field strength information respectively;

[0053...

Embodiment 2

[0065] Such as Figure 4 As shown, the deep fusion and real-time compensation system of micro-inertial measurement information includes:

[0066] An information acquisition module 41, configured to acquire angular velocity information, acceleration information and magnetic field strength information of the research object respectively;

[0067] The real-time compensation module 42 is used to perform real-time compensation on the angular velocity information, the acceleration information and the magnetic field strength information respectively by using a deep learning method, and respectively obtain compensated angular velocity information, compensated acceleration information and compensated magnetic field strength information;

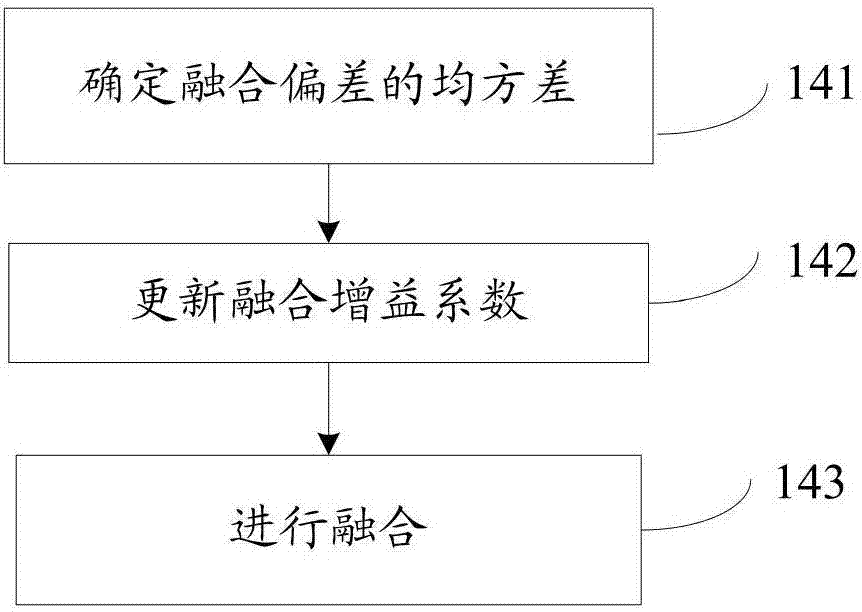

[0068] The Euler angle calculation module 43 is configured to determine a first Euler angle according to the compensated angular velocity information, and determine a second Euler angle according to the compensated acceleration information and the com...

Embodiment 3

[0081] Embodiment 3: The method for deep fusion and real-time compensation of micro-inertial measurement information includes:

[0082] Step 31: Obtain the angular velocity information, acceleration information and magnetic field strength information of the research object respectively:

[0083]Obtain Microelectro Mechanical Systems (MEMS) sensors, including three-axis gyroscopes, three-axis accelerometers, and three-axis magnetometers, which output angular velocity information, acceleration information, and magnetic field strength information respectively, and the three axes of the sensor X-Y-Z Defined as front-right-down, the Euler angle is represented by α-Yaw, β-Pitch, γ-Roll, the carrier attitude is represented by roll angle γ and pitch angle β, and the heading is represented by yaw angle α.

[0084] Step 32: Using a deep learning method to perform real-time compensation on angular velocity information, acceleration information, and magnetic field strength information, re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com