Device and method for evaluating influences of sudden change of working fluid temperature on mechanical integrity of pit shaft

A technology of sudden temperature change and wellbore mechanics, which is applied in the direction of liquid tightness measurement, measurement device, strength characteristics, etc. using liquid/vacuum degree. Enrich the test structure and detect the effect of rich data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with drawings and embodiments.

[0038] It should be pointed out that: on the premise of not departing from the principles of the present invention, relevant technical personnel can also make some improvements and modifications, and these improvements and modifications all belong to the protection scope of the claims of the present invention.

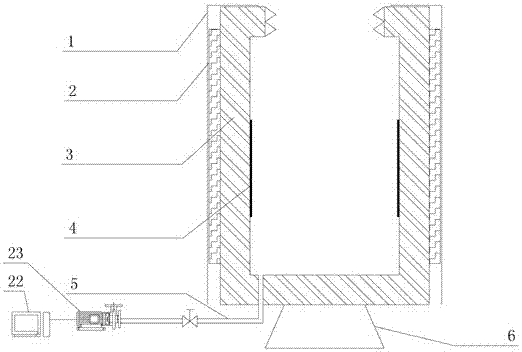

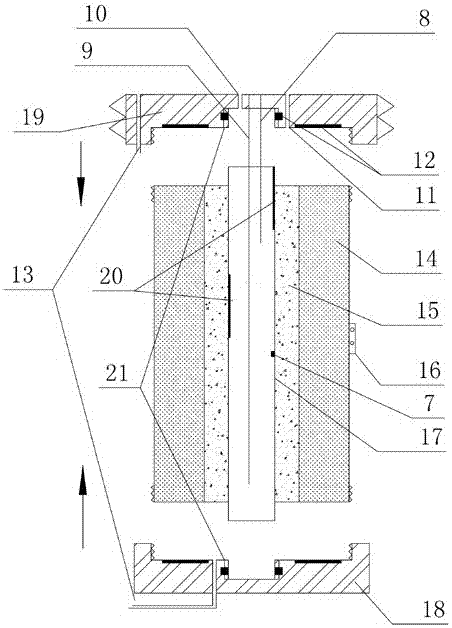

[0039] see figure 1 , figure 2 .

[0040] The evaluation device for the impact of the sudden change of working fluid temperature on the mechanical integrity of the wellbore includes a test body and a working platform. The working platform has a computer 22 and is equipped with a pressure and temperature control terminal.

[0041] The test body includes a bracket 6 and a kettle body 3 on the bracket. The kettle body 3 is a steel hollow cylinder. There is a metal outer cover 1 and an insulation layer 2 outside the kettle body wall. There are heating wires 4 ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com