Neutron reflection spectrometer optical path structure capable of performing rapid switching between polarization mode and non-polarization mode

A non-polarization and reflection spectrum technology, which is applied in material analysis using neutrons, material analysis using wave/particle radiation, instruments, etc. Problems such as polarization neutron reflection experiment, failure to realize sample and detector linkage, etc., to achieve the effect of simple realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

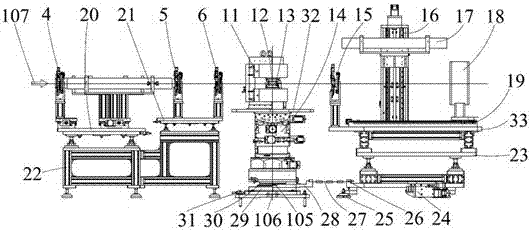

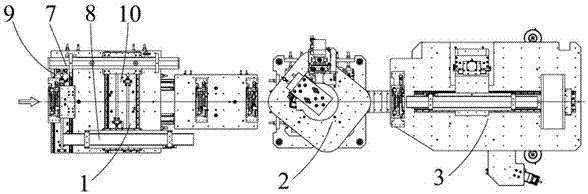

[0046] Such as Figure 1-15 As shown, a neutron reflectance spectrometer optical path structure that can quickly switch between polarized and non-polarized modes, the optical path structure mainly includes incident arms 1, Sample stage 2 and reflection arm 3.

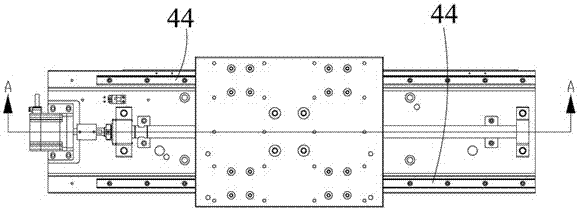

[0047] The incident arm 1 includes a first slit 4, a second slit 5, a third slit 6, a focusing conduit 7, a polarizer 8, a first translation stage 9, a second translation stage 10, a first platform 20, The second platform 21 and the incident arm base 22; wherein the incident arm base 22 is placed on the precision granite ground, and the first platform 20 is fixedly installed on the incident end of the incident arm base 22 along the incident neutron beam direction, the first The second platform 21 is fixedly installed on the exit end of the incident arm base 22 along the direction of the incident neutron beam, and the first translation platform 9 is fixedly installed on the incident end of the first platform 20 along th...

Embodiment 1

[0057] Embodiment 1: Utilize the present invention to carry out common non-polarization mode experiment

[0058] Such as Figure 16 As shown, a neutron optical path structure for a neutron reflectance spectrometer, the optical path structure mainly includes an incident arm 1, a sample stage 2 and a reflective arm that are sequentially placed on the precision granite ground along the direction of the incident neutron beam 3. The incident arm 1 mainly includes a first slit 4, a second slit 5, a third slit 6, a focusing conduit 7, a polarizer 8, a first translation stage 9, a second translation stage 10, a first Platform 20, second platform 21, and incident arm base 22; the sample stage 2 mainly includes a vertical electromagnet 11, a sample 12, a cryostat 13, a third platform 32, a sample attitude adjustment mechanism 14, and a sample stage base 31; The reflective arm 3 mainly includes a fourth slit 15, a lifting platform 16, a polarization analyzer 17, a detector 18, a third t...

Embodiment 2

[0059] Embodiment 2: Using the present invention to carry out high-throughput non-polarization mode experiments

[0060] Such as Figure 17 As shown, a neutron optical path structure for a neutron reflectance spectrometer, the optical path structure mainly includes an incident arm 1, a sample stage 2 and a reflective arm that are sequentially placed on the precision granite ground along the direction of the incident neutron beam 3. The incident arm 1 mainly includes a first slit 4, a second slit 5, a third slit 6, a focusing conduit 7, a polarizer 8, a first translation stage 9, a second translation stage 10, a first Platform 20, second platform 21, and incident arm base 22; the sample stage 2 mainly includes a vertical electromagnet 11, a sample 12, a cryostat 13, a third platform 32, a sample attitude adjustment mechanism 14, and a sample stage base 31; The reflective arm 3 mainly includes a fourth slit 15, a lifting platform 16, a polarization analyzer 17, a detector 18, a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com