Device and method for evaluating water invasion resistance of oil well cement slurry in setting waiting process

A cementing cement slurry and cement slurry technology, applied in the direction of material resistance, to achieve the effect of improving the ability of water intrusion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

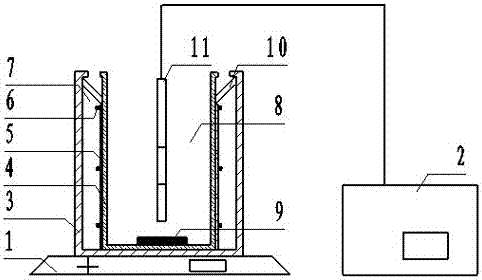

[0024] see figure 1 .

[0025] The evaluation device for water intrusion resistance of cement slurry during the waiting setting process is mainly composed of a magnetic stirrer 1 , a conductivity tester 2 , and a kettle body 3 . The kettle body 3 is placed on the magnetic stirrer 1 .

[0026] Inside the kettle body, there are cement slurry 7, iron filter screen 4 and simulated formation water 8 from outside to inside. Winding 3-8 layers of nylon filter screen 5, the bottom of which has no holes and is in close contact with the bottom of the kettle body or fits seamlessly. The multi-layer nylon filter screen is sealed on the surface of the iron screen screen by rubber ring 6 to isolate oil we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com