Gas humidity monitoring device for nuclear reactors

A technology for nuclear reactors and monitoring devices, which is applied in the fields of nuclear reactor monitoring, reactors, and greenhouse gas reduction, etc., can solve the problems of software without V&V certification, gas can not return to the main pipeline, and can not achieve zero emission requirements of radioactive gas in the primary circuit, and can meet the requirements of reliable and reliable Sexual requirements, fast response, and zero-emission effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

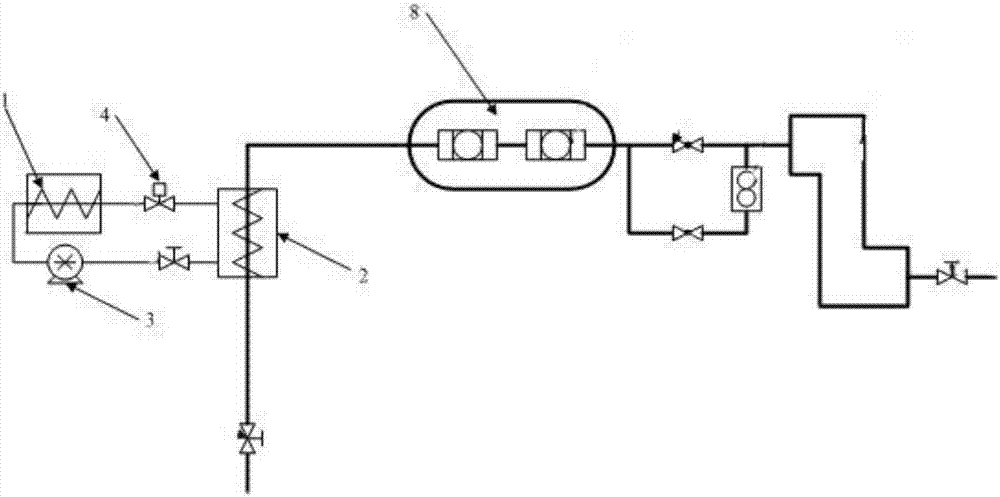

[0031] Such as figure 1 A gas humidity monitoring device for a nuclear reactor is shown, comprising:

[0032] A cooling control unit used to cool the high-temperature sampling gas of the primary circuit to a certain temperature range;

[0033] Sampling unit for sampling the cooled gas;

[0034] A humidity detection unit for detecting the humidity of the gas in the sampling unit;

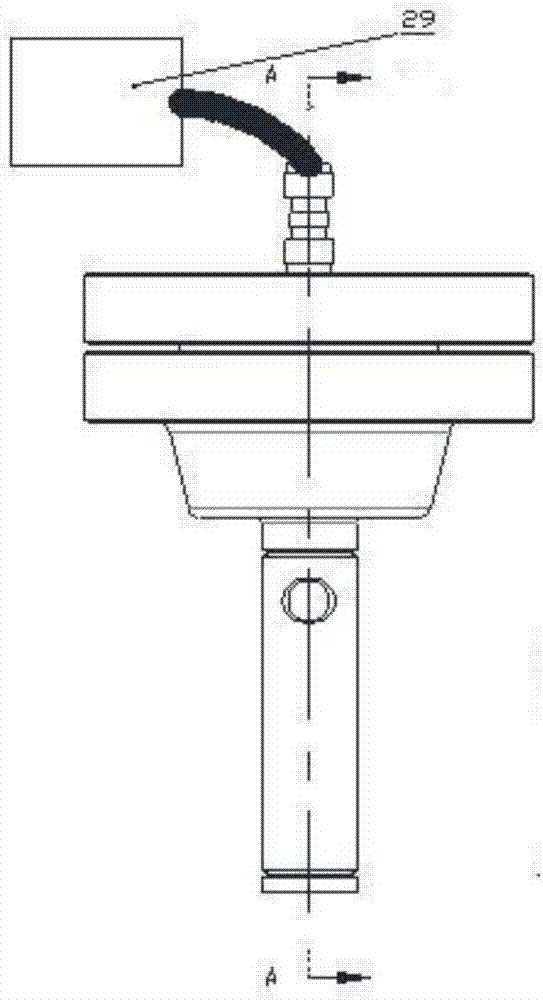

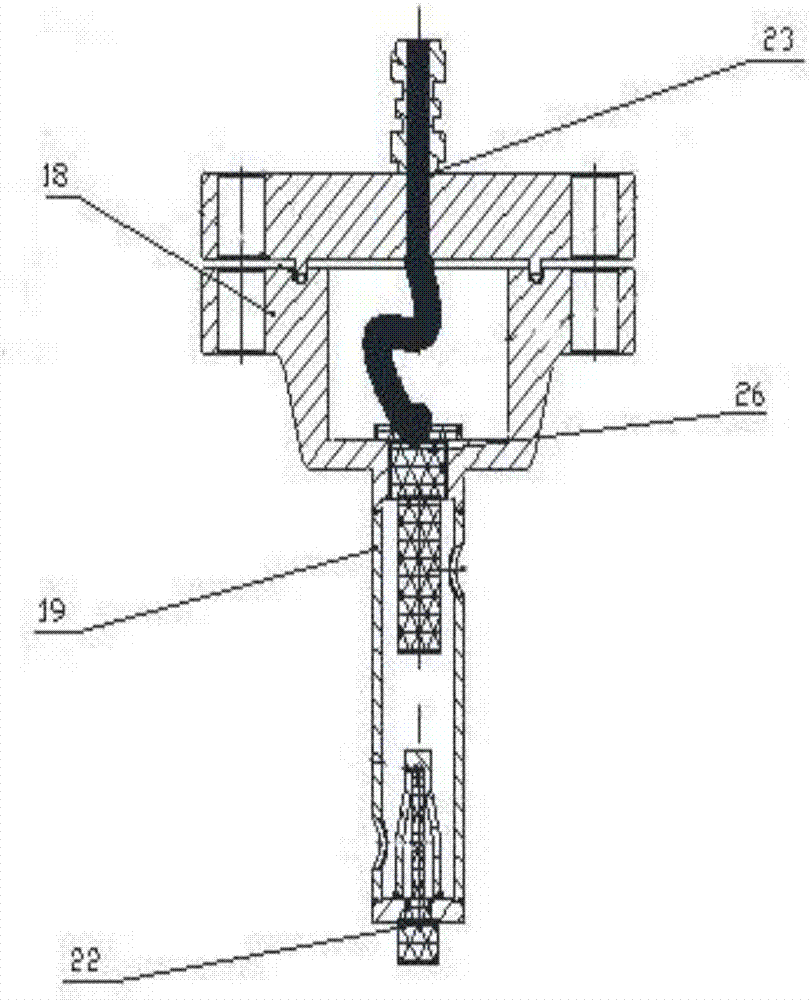

[0035] The humidity detection unit includes a humidity sensing element 26 and a signal conversion circuit 29 for converting the output signal of the humidity sensing element 26 into a signal recognizable by the reactor protection system.

Embodiment 2

[0037] This embodiment optimizes the cooling control unit on the basis of the above embodiments, that is, the cooling control unit includes a casing heat exchanger 2 and a natural air-cooled heat exchanger connected to the cooling medium passage of the casing heat exchanger 2 1 and a coolant flow control device, the coolant flow control device includes a temperature measuring element 22 for collecting temperature information of the sampling unit, a circulating pump 3 and a temperature control valve all arranged on the cooling medium passage of the casing heat exchanger 4. The signal from the temperature measuring element 22 drives the valve position of the temperature control valve 4 to move. The casing heat exchanger 2 may be a casing water-cooled heat exchanger. The sampled gas is cooled down through the casing heat exchanger, and the cooling medium used for gas cooling is driven by the circulation pump 3 to circulate and flow through the natural air cooling heat exchanger 1...

Embodiment 3

[0039] In this embodiment, on the basis of the above embodiments, a filter unit 8 is set in the pressure tube between the cooling control unit and the sampling unit, and the filter unit 8 is used to remove tiny particles in the gas. The filter unit is packaged in the pressure tube, which can Effectively guarantee its airtightness.

[0040] Further, the filter unit may adopt a two-stage filter structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com