Substrate annealing device

An annealing device and substrate technology, applied in the manufacture of electrical components, circuits, semiconductor/solid-state devices, etc., can solve the problems of high cost and low processing efficiency of laser annealing process, so as to improve the service life, increase the number of transmission and processing, and improve the The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

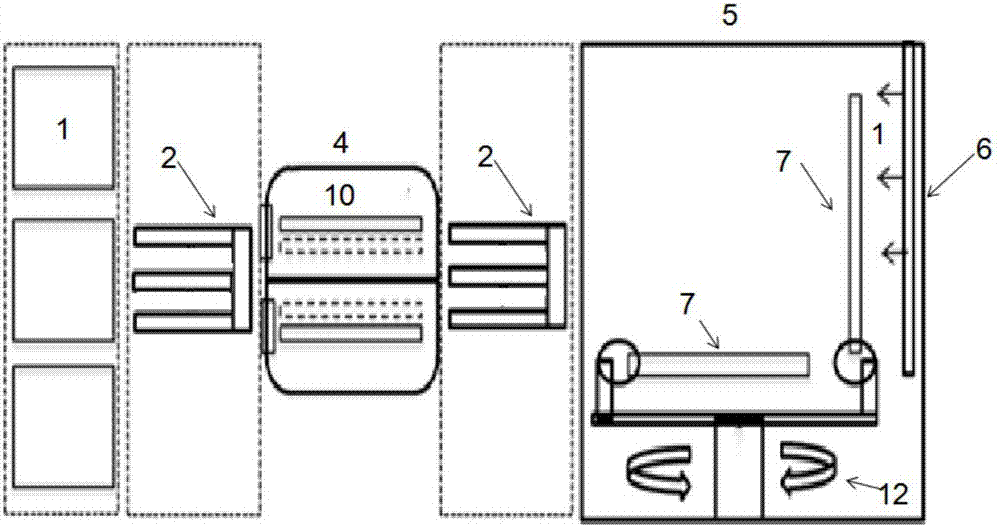

[0035] Such as figure 1 Shown is a substrate annealing device of the present invention, which mainly includes: a preheating chamber 4 and an annealing chamber 5 . The preheating chamber 4 is arranged upstream of the annealing chamber 5 , and the substrate 1 enters the preheating chamber 4 through the manipulator 2 . A heater is arranged in the preheating chamber 4, and the substrate 1 is preheated by the heater, wherein the heating temperature in the preheating chamber 4 ranges from 0°C to 600°C. After the preheating is completed, the substrate 1 is transferred to the annealing chamber 5 by the manipulator 2 for annealing treatment.

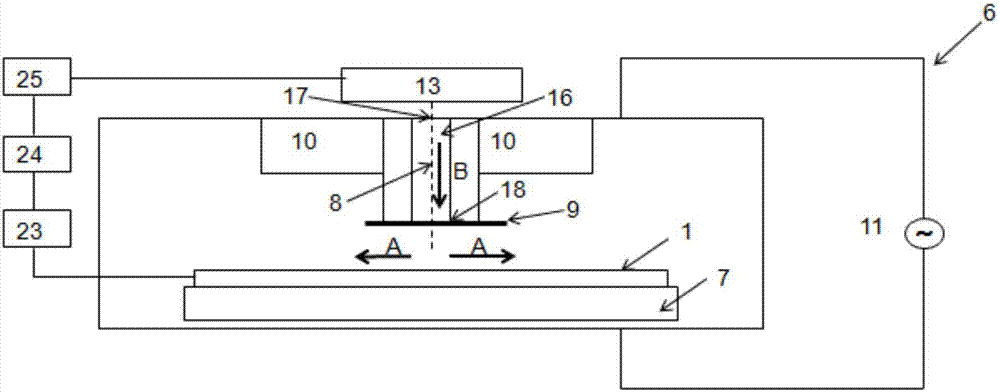

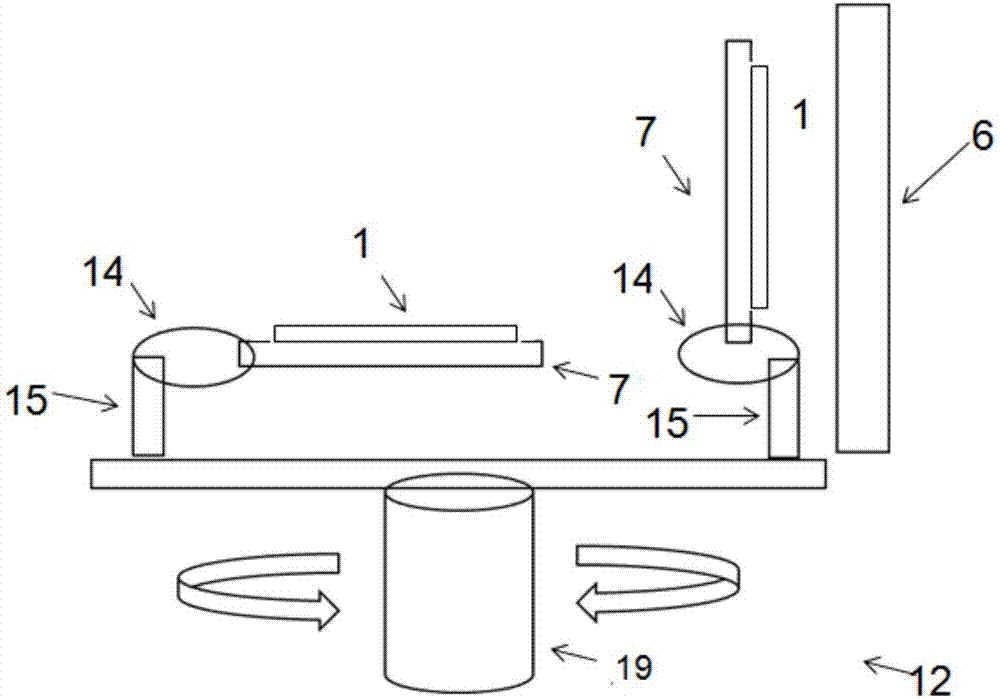

[0036]The annealing chamber 5 in this embodiment is provided with a laser annealing device 6 and a rotating device 12 , wherein the laser annealing device 6 is used for annealing the surface of the substrate 1 . Such as image 3 As shown, the rotating device 12 in this embodiment is provided with a plurality of irradiation positions 15 for fix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com