Power battery alternating current varying current gradient heating method

A power battery and heating method technology, which is applied to battery/fuel cell control devices, secondary batteries, circuits, etc., can solve the problems of not considering the safety performance of the battery, the inability to effectively limit the battery voltage, and shortening the battery life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The power battery involved in the present invention includes a power battery unit, a power battery pack, or a grouped power battery pack.

[0023] The present invention uses OCV to represent the open circuit voltage, I to represent the input AC excitation current of the power battery, and T to be the temperature of the power battery.

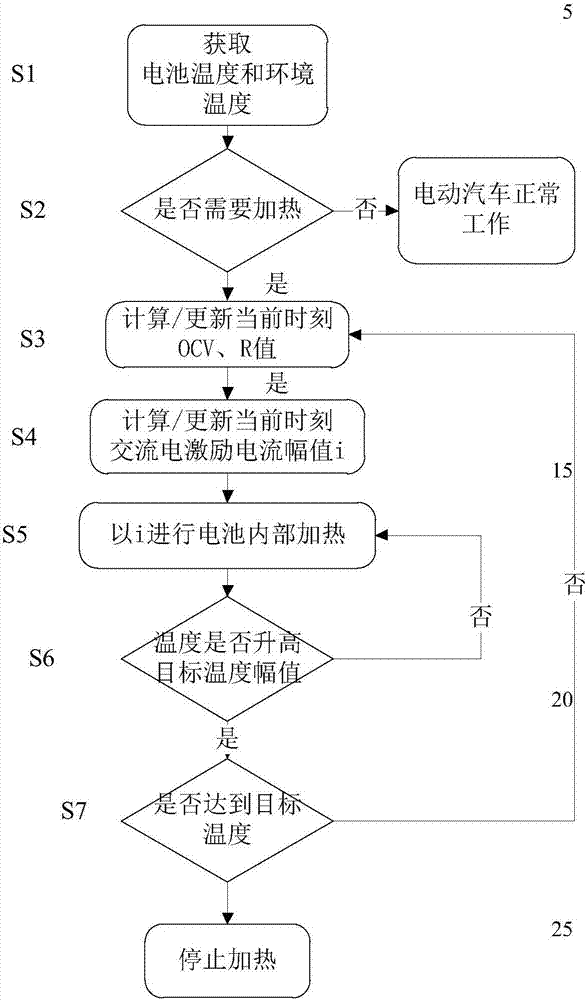

[0024] The power battery alternating current variable current gradient heating method described in the present invention is as attached figure 1 shown.

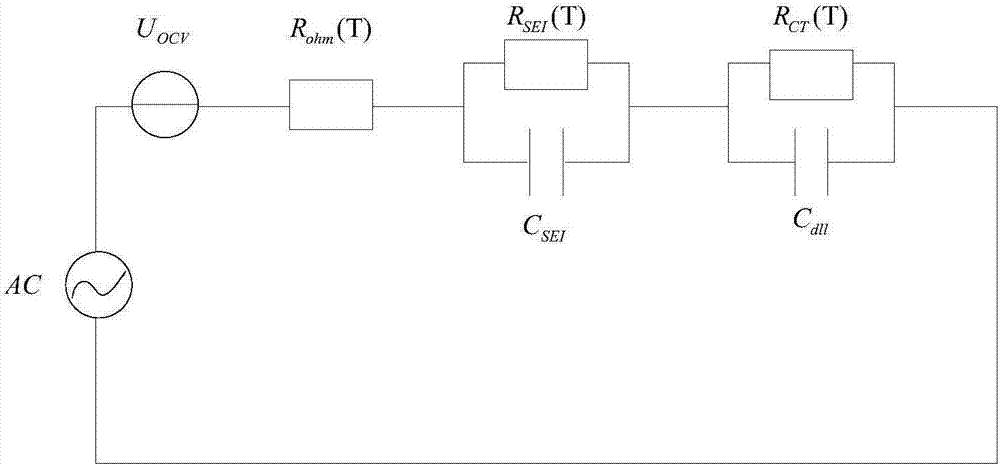

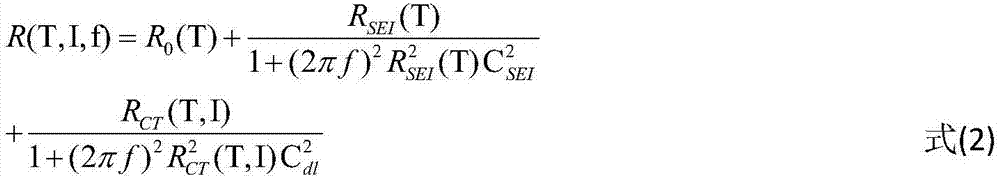

[0025] The method for stepwise heating of a power battery with an alternating current variable current according to the present invention includes: establishment of an OCV-T curve, establishment of an R-T model, and calculation of an alternating current excitation current amplitude. The following describes each of the above parts in detail:

[0026] First of all, the establishment method of the OCV-T curve is as follows. The OCV and T of the power battery have a one-to-one mapping rela...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com