Permanent magnet motor rotor punching sheet structure

A rotor punching, permanent magnet motor technology, applied in the shape/style/structure of the magnetic circuit, the rotating parts of the magnetic circuit, the magnetic circuit, etc., can solve the problem of material waste, and achieve uniform magnetic field density, small space, and strong magnetic field. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

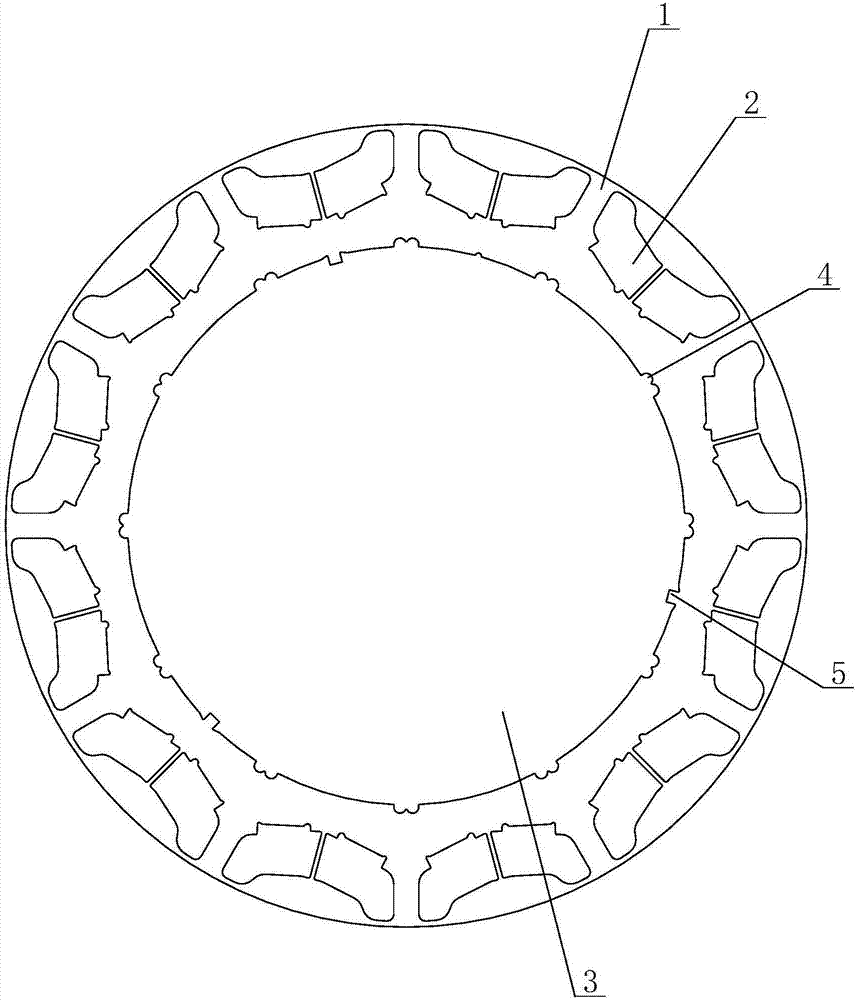

[0015] see figure 1 as shown, figure 1 It is a structural schematic diagram of the punching structure of the permanent magnet motor rotor provided in Embodiment 1 of the present invention.

[0016] In this embodiment, a permanent magnet motor rotor stamping structure includes a rotor stamping formed by a silicon steel sheet 1, a permanent magnet 2, a welding groove 4, and a positioning groove 5. There are gaps at a certain distance, the rotor punch has 24 slots, the outer diameter of the rotor punch is 255mm-260mm, the slot width of the slot is 16mm-18mm, the upper top surface of the slot to the rotor The outer circle of the stamping sheet has a closed section of 2mm-5mm, and the distance between two adjacent grooves is 1mm-3mm, which produces a stronger and more uniform magnetic field, which is m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Notch width | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com