Production method of crisp black garlic slices by using variable temperature and pressure difference puffing and drying technology

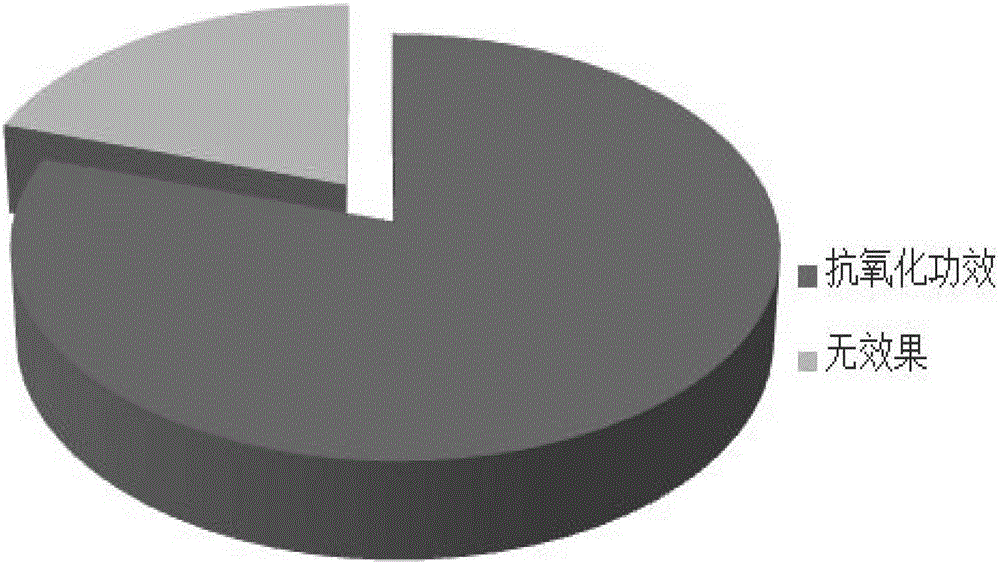

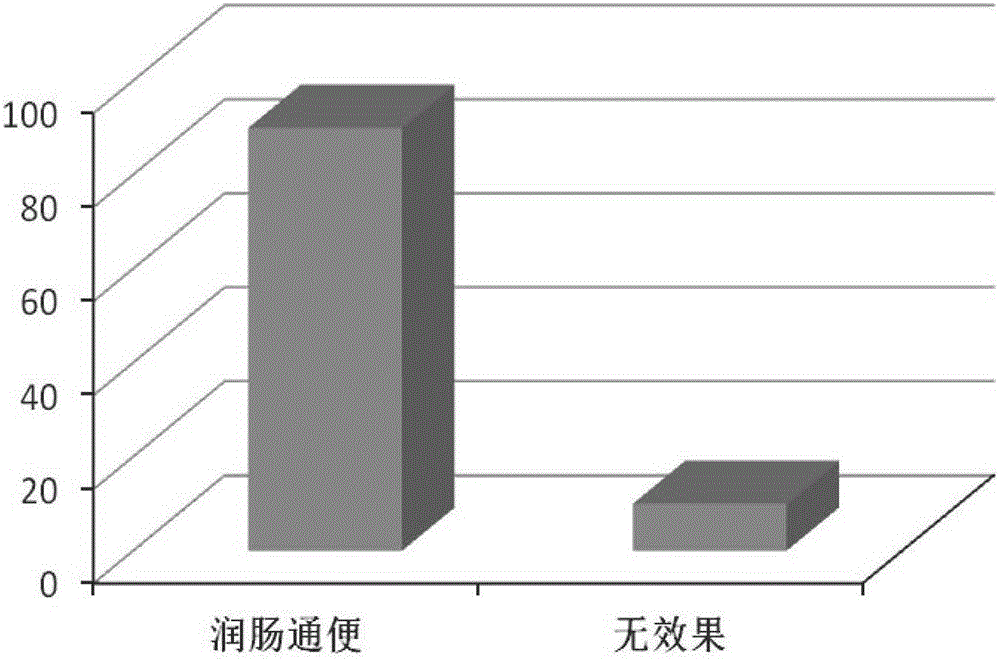

A technology of variable temperature and pressure difference puffing and black garlic slices, which is applied in the fields of application, food forming, food science, etc., can solve problems that have not been reported before, achieve broad market prospects, prevent and treat high blood pressure, and maintain the effects of intestinal ecology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A method for producing black garlic crisps by utilizing variable temperature and pressure difference puffing and drying technology, the process parameters of which are as follows:

[0034] Pretreatment conditions: slice thickness: 3mm;

[0035] Constant temperature drying temperature: 50°C;

[0036] Constant temperature drying time: 4h;

[0037] Variable temperature and pressure difference expansion conditions:

[0038] Expansion temperature: 65°C;

[0039] Expansion time: 4.5h;

[0040] Pressure difference: 0.1MPa;

[0041] Dead time: 10min;

[0042] Evacuation temperature: 55°C;

[0043] Evacuation time: 90min.

[0044] Specific steps are as follows:

[0045] (1) Pretreatment conditions: slice the black garlic to obtain garlic slices; place the garlic slices in a constant temperature drying oven at a temperature of 50°C and dry for 4 hours to obtain pretreated black garlic slices;

[0046] (2) Conditions for variable temperature and pressure difference puffin...

Embodiment 2

[0048] A method for producing black garlic crisps by utilizing variable temperature and pressure difference puffing and drying technology, the process parameters of which are as follows:

[0049] Pretreatment conditions: slice thickness: 3mm;

[0050] Constant temperature drying temperature: 50°C;

[0051] Constant temperature drying time: 4h;

[0052] Variable temperature and pressure difference expansion conditions:

[0053] Expansion temperature: 60°C;

[0054] Expansion time: 4.0h;

[0055] Pressure difference: 0.1MPa;

[0056] Dead time: 10min;

[0057] Evacuation temperature: 60°C;

[0058] Evacuation time: 60min.

[0059] Specific steps are as follows:

[0060] (1) Pretreatment conditions: slice the black garlic to obtain garlic slices; place the garlic slices in a constant temperature drying oven at a temperature of 50°C and dry for 4 hours to obtain pretreated black garlic slices;

[0061](2) Conditions for variable temperature and pressure difference puffing...

Embodiment 3

[0063] A method for producing black garlic crisps by utilizing variable temperature and pressure difference puffing and drying technology, the process parameters of which are as follows:

[0064] Pretreatment conditions: slice thickness: 3mm;

[0065] Constant temperature drying temperature: 50°C;

[0066] Constant temperature drying time: 4h;

[0067] Variable temperature and pressure difference expansion conditions:

[0068] Expansion temperature: 55°C;

[0069] Expansion time: 4.0h;

[0070] Pressure difference: 0.1MPa;

[0071] Dead time: 10min;

[0072] Evacuation temperature: 50°C;

[0073] Evacuation time: 80min.

[0074] Specific steps are as follows:

[0075] (1) Pretreatment conditions: slice the black garlic to obtain garlic slices; place the garlic slices in a constant temperature drying oven at a temperature of 50°C and dry for 4 hours to obtain pretreated black garlic slices;

[0076] (2) Variable temperature and pressure difference puffing conditions: p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com