Constant-temperature leaf wetting method for tobacco

A technology for moisturizing leaves and tobacco leaves, which is applied in the fields of tobacco, tobacco preparation, application, etc., can solve the problems of low usability and poor quality of finished re-baking tobacco, and achieves the solution of low usability, bright and uniform color of tobacco leaves, sweetness and rejuvenation. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] A method for moistening tobacco leaves at a constant temperature according to the present invention will be further described below in conjunction with specific examples.

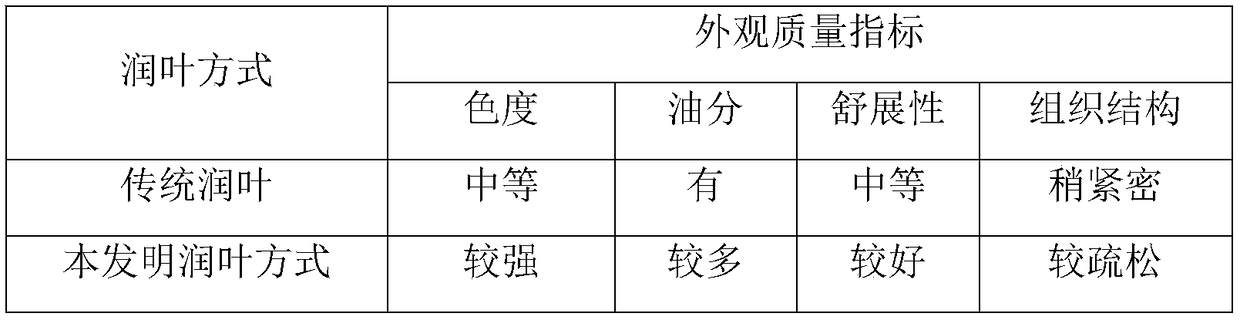

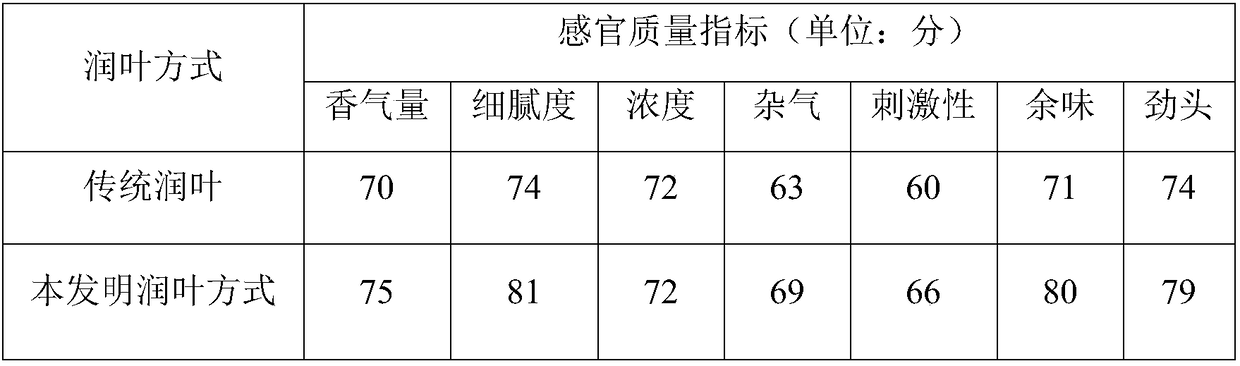

[0018] In the first embodiment of the present invention, the 2017 Chongqing Fengjieyun 87C3F tobacco leaves were moistened by using traditional technology and full steam moistening respectively, as follows:

[0019] Traditional process of leaf moistening: According to the medium tobacco leaf processing parameters stipulated in YC / T146-2001, the leaves are moistened by mixing soda and water.

[0020] Full steam leaf moistening: first preheat the leaf moistening cylinder, input hot air into the leaf moistening cylinder, let the temperature inside the leaf moistening cylinder reach 80℃~120℃; secondly, set the steam pressure value to 0.2~0.5MPa, Input steam; then input tobacco leaves into the leaf moistening cylinder for the first moistening of leaves, reduce the temperature in the leaf moistening cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com