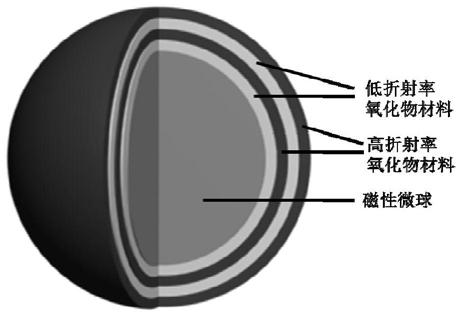

Magnetic photonic crystal microsphere material and preparation method thereof

A magnetic photonic crystal and magnetic microsphere technology, applied in metal material coating process, gaseous chemical plating, coating and other directions, can solve the problems of poor mechanical strength, complicated preparation process, etc. The effect of good mechanical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

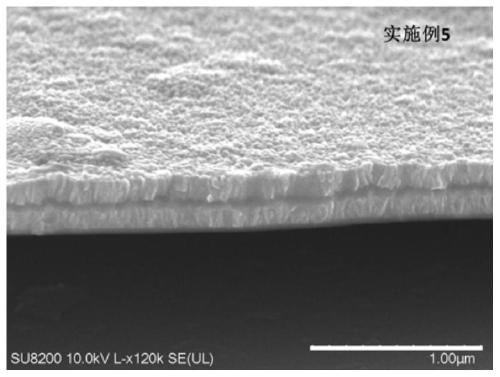

Examples

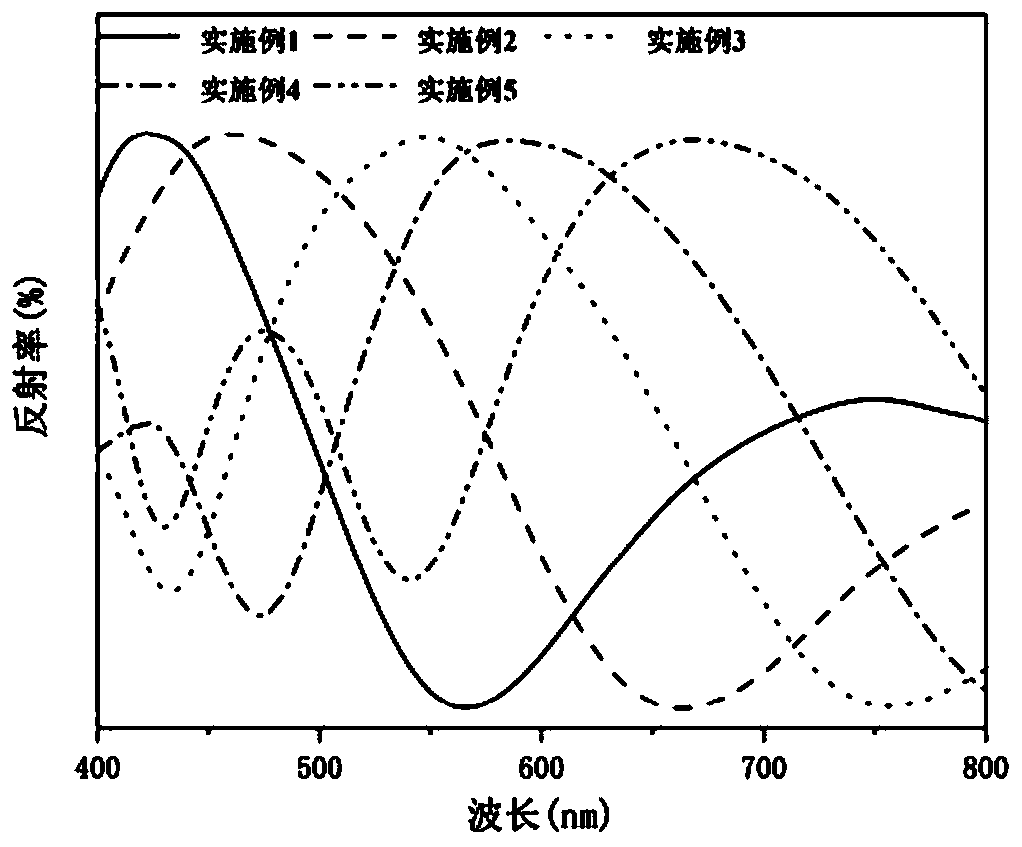

Embodiment 1

[0041] This embodiment discloses a method for preparing magnetic photonic crystal microspheres, specifically as follows:

[0042] The magnetic microspheres (Fe) with a diameter of 10 μm were ultrasonically cleaned in acetone and ethanol for 3 minutes to remove oil and other impurities on the surface of the microspheres, and then the magnetic microspheres were placed in a vacuum drying oven at a temperature of 20 ° C. Dry for 60 minutes under the condition of 0.05Mpa and pressure to remove excess solvent; then use a plasma cleaner to activate the magnetic microspheres, and activate the treatment for 5 minutes under the conditions of power of 10W, temperature of 20°C and pressure of 15Pa; The processed magnetic microspheres are placed in an atomic layer deposition system, and the temperature of the reaction chamber is raised to 200° C. under vacuum conditions, and high-purity nitrogen gas with a purity of 99.99% is used as a carrier gas, and the flow rate of the carrier gas is 20...

Embodiment 2

[0044] This embodiment discloses a method for preparing magnetic photonic crystal microspheres, specifically as follows:

[0045] The magnetic microspheres (Fe) with a diameter of 50 μm were ultrasonically cleaned in acetone and ethanol for 3 minutes to remove oil and other impurities on the surface of the microspheres, and then the magnetic microspheres were placed in a vacuum drying oven at a temperature of 20 ° C. Dry for 60 minutes under the condition of 0.05Mpa and pressure to remove excess solvent; then use a plasma cleaner to activate the magnetic microspheres, and activate the treatment for 5 minutes under the conditions of power of 10W, temperature of 20°C and pressure of 15Pa; The processed magnetic microspheres are placed in an atomic layer deposition system, and the temperature of the reaction chamber is raised to 200° C. under vacuum conditions, and high-purity nitrogen gas with a purity of 99.99% is used as a carrier gas, and the flow rate of the carrier gas is 20...

Embodiment 3

[0047] This embodiment discloses a method for preparing magnetic photonic crystal microspheres, specifically as follows:

[0048] The magnetic microspheres (Fe) with a diameter of 100 μm were ultrasonically cleaned in acetone and ethanol for 3 minutes to remove oil and other impurities on the surface of the microspheres, and then the magnetic microspheres were placed in a vacuum drying oven at a temperature of 20 ° C. Dry for 60 minutes under the condition of 0.05Mpa and pressure to remove excess solvent; then use a plasma cleaner to activate the magnetic microspheres, and activate the treatment for 5 minutes under the conditions of power of 10W, temperature of 20°C and pressure of 15Pa; The processed magnetic microspheres are placed in an atomic layer deposition system, and the temperature of the reaction chamber is raised to 200° C. under vacuum conditions, and high-purity nitrogen gas with a purity of 99.99% is used as a carrier gas, and the flow rate of the carrier gas is 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com