Printing pulp material for towels

A technology for printing paste and towels, applied in the field of printing and dyeing, can solve the problems of poor performance, poor permeability, low color fastness, etc., and achieve the effects of uniform and bright color, strong colorability and simple preparation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

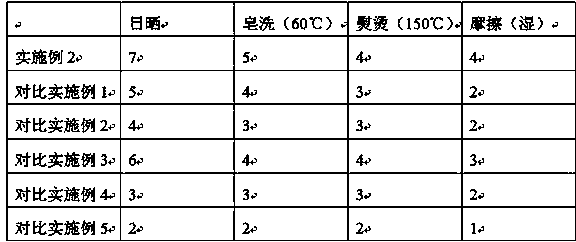

Examples

Embodiment 1

[0024] A printing slurry for towels, made of the following materials in parts by weight:

[0025] 20 parts of reactive dyes, 10 parts of modified sweet potato starch, 1 part of sodium carbonate, 0.5 parts of urea, 2 parts of nonylphenol polyoxyethylene ether, 1 part of sodium hexametaphosphate, 3 parts of zein, 3 parts of epoxy resin Soybean oil, 7 parts of ethyl acetate, 50 parts of deionized water.

[0026] Further, the preparation method of described modified sweet potato starch comprises the steps:

[0027] (1) Put the sweet potato starch into the acid solution and soak it continuously for 8 minutes, then add lye dropwise to it, adjust the overall pH value to 6.5~7.0, and obtain the mixture I for later use;

[0028] (2) Put the mixture I obtained in step (1) into the reactor, then add nano-graphene, corn fiber gum, sodium pyrophosphate, disodium edetate and chitin into the reactor, and then add The reaction kettle was heated and pressurized, and ultrasonic treatment was ...

Embodiment 2

[0038] A printing slurry for towels, made of the following materials in parts by weight:

[0039] 23 parts of reactive dyes, 12 parts of modified sweet potato starch, 2 parts of sodium carbonate, 1 part of urea, 3 parts of nonylphenol polyoxyethylene ether, 1.5 parts of sodium hexametaphosphate, 5 parts of zein, 4 parts of epoxy Soybean oil, 8 parts of ethyl acetate, 53 parts of deionized water.

[0040] Further, the preparation method of described modified sweet potato starch comprises the steps:

[0041] (1) Put the sweet potato starch into the acid solution and soak it continuously for 9 minutes, then add the lye dropwise to it, adjust the overall pH value to 6.5~7.0, and obtain the mixture I for later use;

[0042] (2) Put the mixture I obtained in step (1) into the reactor, then add nano-graphene, corn fiber gum, sodium pyrophosphate, disodium edetate and chitin into the reactor, and then add The reaction kettle was heated and pressurized, and ultrasonic treatment was c...

Embodiment 3

[0052] A printing slurry for towels, made of the following materials in parts by weight:

[0053] 25 parts of reactive dyes, 15 parts of modified sweet potato starch, 3 parts of sodium carbonate, 1.5 parts of urea, 4 parts of nonylphenol polyoxyethylene ether, 2 parts of sodium hexametaphosphate, 6 parts of zein, 5 parts of epoxy Soybean oil, 9 parts of ethyl acetate, 55 parts of deionized water.

[0054] Further, the preparation method of described modified sweet potato starch comprises the steps:

[0055] (1) Put the sweet potato starch into the acid solution and soak it continuously for 10 minutes, then add the lye dropwise to it, adjust the overall pH value to 6.5~7.0, and obtain the mixture I for later use;

[0056] (2) Put the mixture I obtained in step (1) into the reactor, then add nano-graphene, corn fiber gum, sodium pyrophosphate, disodium edetate and chitin into the reactor, and then add The reaction kettle was heated and pressurized, and ultrasonic treatment was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com