Corn husk for willow weaving

A corn husk and hydroxylation technology, used in wood treatment, wood processing appliances, impregnated wood, etc., can solve the problems of poor performance of woven handicrafts, cannot be well promoted, low fiber toughness, etc., to improve mechanical quality and life. , The effect of improving comprehensive mechanical properties and reducing fracture rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

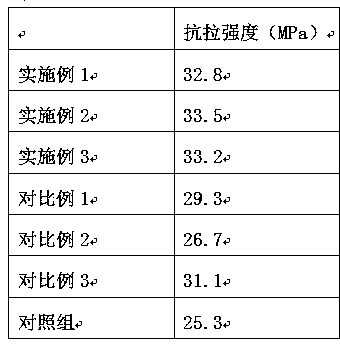

Examples

Embodiment 1

[0017] The invention relates to corn husks for willow weaving. The surface hydroxylation treatment of the corn husks is carried out to obtain the hydroxylated corn husks, and then the hydroxylated corn husks are irradiated with a lower energy and a certain dose of ion beams.

[0018] Further, the surface hydroxylation treatment method of the corn bran is:

[0019] Soak corn husks in potassium citrate ethanol solution at 50°C for 2 hours, then filter, wash with deionized water until neutral, dry naturally, and then immerse the treated corn husks in hydrogen with a mass concentration of 10%. In sodium oxide solution, adjust the temperature to 55°C, keep it warm for 4 hours, then filter, wash with deionized water until neutral, dry naturally, then immerse in citric acid solution with a mass concentration of 20%, and soak at 40°C for 3 hours, then filtered, washed with deionized water until neutral, and dried in vacuum to obtain hydroxylated corn bran.

[0020] Further, the mass ...

Embodiment 2

[0027] The invention relates to corn husks for willow weaving. The surface hydroxylation treatment of the corn husks is carried out to obtain the hydroxylated corn husks, and then the hydroxylated corn husks are irradiated with a lower energy and a certain dose of ion beams.

[0028] Further, the surface hydroxylation treatment method of the corn bran is:

[0029] Soak corn husks in potassium citrate ethanol solution at 55°C for 2 hours, then filter, wash with deionized water until neutral, dry naturally, and then immerse the treated corn husks in hydrogen with a mass concentration of 12%. In sodium oxide solution, adjust the temperature to 58°C, keep warm for 4 hours, then filter, wash with deionized water until neutral, dry naturally, then immerse in citric acid solution with a mass concentration of 20-22%, at 40°C Soak for 3 hours, then filter, wash with deionized water until neutral, and vacuum dry to obtain hydroxylated corn bran.

[0030] Further, the mass ratio of pota...

Embodiment 3

[0037] The invention relates to corn husks for willow weaving. The surface hydroxylation treatment of the corn husks is carried out to obtain the hydroxylated corn husks, and then the hydroxylated corn husks are irradiated with a lower energy and a certain dose of ion beams.

[0038] Further, the surface hydroxylation treatment method of the corn bran is:

[0039] Soak corn husks in potassium citrate ethanol solution at 52°C for 2 hours, then filter, wash with deionized water until neutral, dry naturally, and then immerse the treated corn husks in hydrogen with a mass concentration of 11%. In sodium oxide solution, adjust the temperature to 56°C, keep it warm for 4 hours, then filter, wash with deionized water until neutral, dry naturally, then immerse in citric acid solution with a mass concentration of 21%, soak at 40°C for 3 hours, then filtered, washed with deionized water until neutral, and dried in vacuum to obtain hydroxylated corn bran.

[0040] Further, the mass rati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com