Operation control method for precise electrolytic machining

A technology of operation control and control method, applied in electric machining equipment, special circuits for machining, circuits, etc., can solve the problem of difficulty in improving machining accuracy and machining stability, unstable product exchange rate in machining gaps, and failure to achieve precision machining of metal parts, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0048] The present invention proposes an operation control method for precision electrolytic machining. By defining and controlling the basic parameters of the electrolyte, the parameters of various machining states are calculated and processed, and the machining voltage, pulse duty ratio, and process voltage are precisely controlled. The speed is given to meet the power demand corresponding to the processing gap, so as to achieve a steady-state electrochemical reaction.

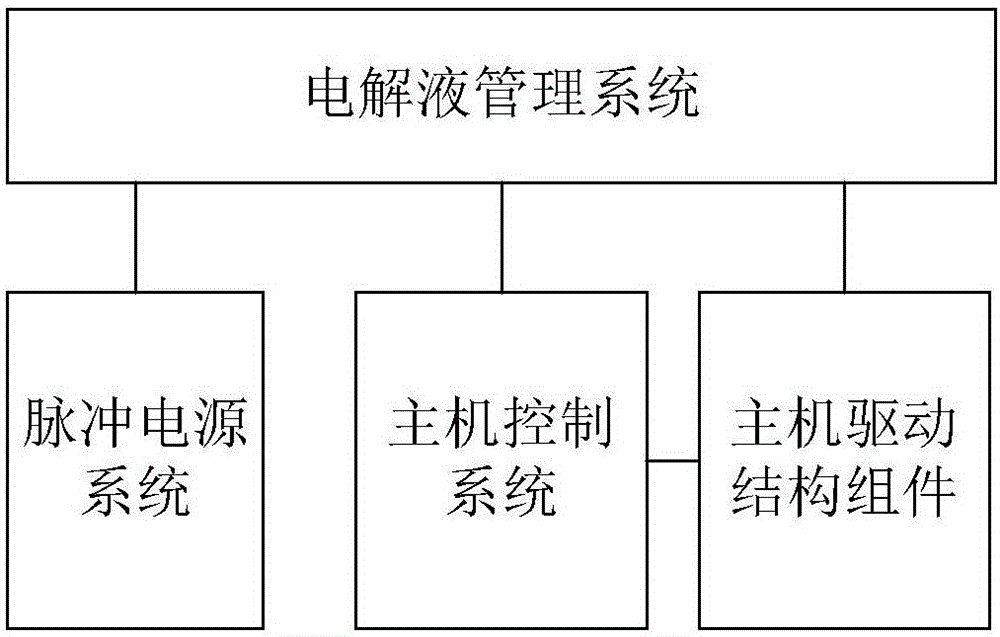

[0049] see figure 1 , The control system of precision electrolytic machining mainly includes the host control system, the host drive structural components, the pulse power supply system, and the electrolyte management system. Among them: the host control system can be realized by industrial controllers such as PLC, CNC, various driving devices, and sensors; the hos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com