Cross-laminated wood processing equipment

A processing equipment and cross-lamination technology, which is applied in wood processing equipment, veneer presses, manufacturing tools, etc., can solve the problems of long gluing and curing time, short opening time, and unsatisfactory conditions, and achieve strong domestic and foreign technological advantages. High production capacity and low installation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

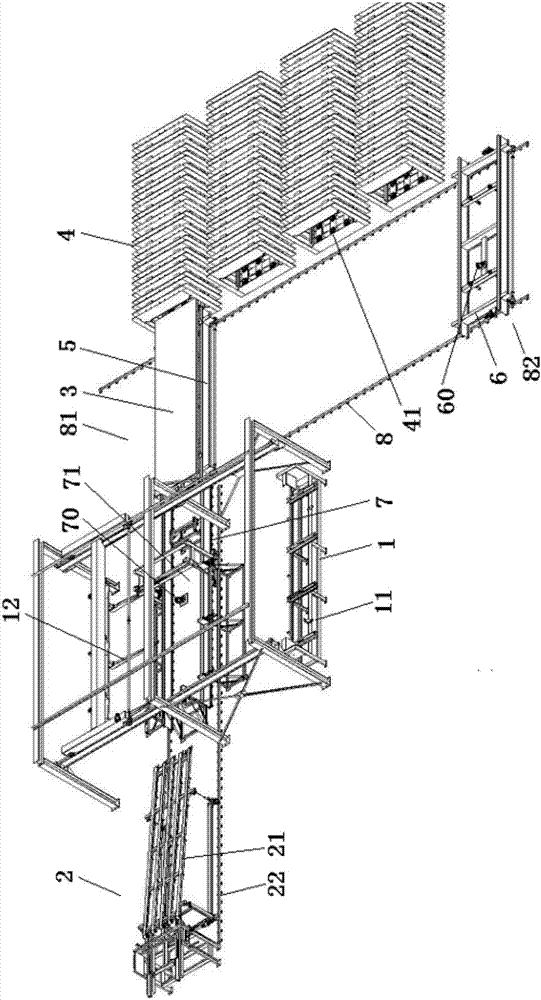

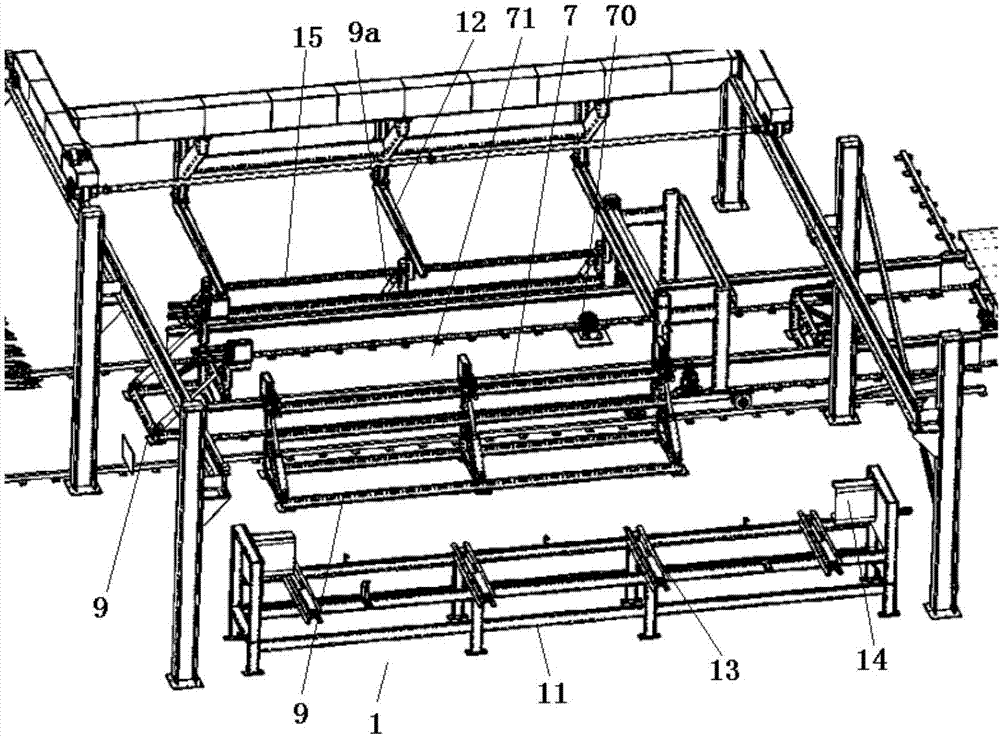

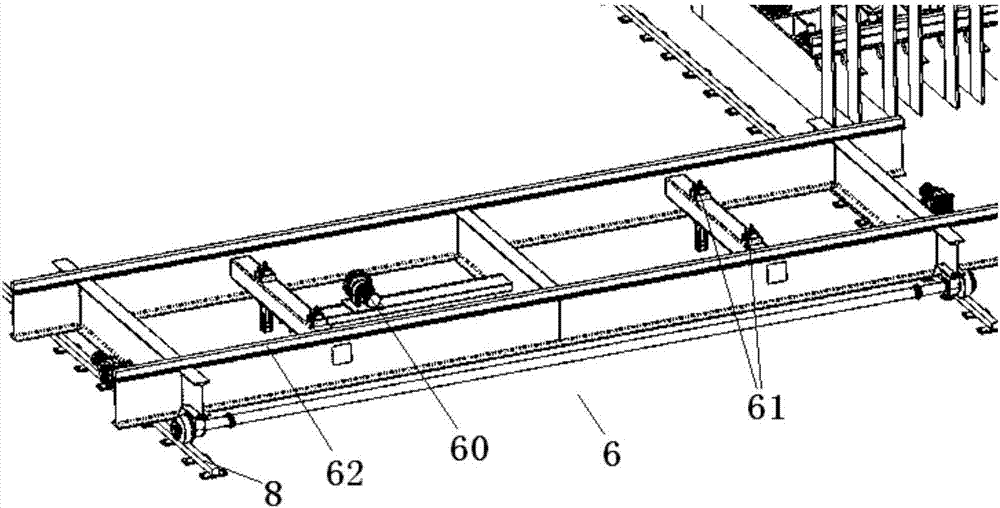

[0033] Such as figure 1 As shown, the cross-laminated wood processing equipment of the present invention includes a vertical plate feeding mechanism 1, a horizontal plate feeding mechanism 2, a glue spraying mechanism, a plurality of paving vehicles 3, a plurality of presses 4, a transfer vehicle 5 and an unloading mechanism. car6.

[0034] The longitudinal track 7 is arranged on one side of the transverse track 8 , one end is vertically close to the transverse track 8 , the other end is provided with a horizontal plate feeding mechanism 2 , and the side of the longitudinal track 7 is provided with a vertical plate feeding mechanism 1 . A plurality of presses 4 are arranged on the other side of the transverse track 8 , and the material opening 41 of each press 4 is all facing the transverse track 8 . A group of billet stations 71 is set on the longitudinal rail 7, and a pavement vehicle can move from the billet assembly station 71 along the longitudinal rail 7 to the directio...

Embodiment 2

[0057] On the basis of Example 1, in order to further improve work efficiency, after the blank assembly on the pavement vehicle at the blank assembly station 71 is completed, it can continue to be superimposed on it and carry out the next blank assembly continuously. During the compaction, the device of the present invention is also provided with a film covering mechanism (not shown in the figure). The upper surface of the wood is covered with a layer of film, and then the second blank is stacked, so that the cross-laminated wood of the second blank and the first blank are separated by the film. All the other are identical with embodiment 1.

[0058]In other embodiments, it is also possible to carry out multiple blank assembly on the same pavement vehicle, just repeat the above process, but it is necessary to ensure that the total height of the pavement vehicle and the blank assembly formed on it can freely enter and exit the press 4 feed port, and does not exceed the working...

Embodiment 3

[0060] combine figure 2 and Figure 5 As shown, on the basis of Embodiment 1 and Embodiment 2, in order to further ensure the orderliness of each layer of horizontal plates, vertical plates and blank formation, a plurality of adjustment mechanisms 9 are also set around the blank formation station 71 to adjust The mechanism 9 includes a bracket 91 , an adjustment frame 93 hinged on the bracket and driven to turn over by the first hydraulic cylinder 92 , the fixed end of the first hydraulic cylinder 92 is fixed on the bracket, and the telescopic end is hinged on the adjustment frame 93 . An adjustment block 95 that can be driven by the second hydraulic cylinder 94 to move is arranged on the adjustment frame 93 . All the other are identical with embodiment 1, embodiment 2.

[0061] When the first hydraulic cylinder 92 shrinks, the drive adjustment frame 93 is turned down to the height of the paving vehicle lower than the billet forming station 71, so as to avoid affecting the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com