Closed-loop control method for ignition energy of natural gas engine

A technology of ignition energy and closed-loop control, which is applied in the direction of engine ignition, ignition controller, electric spark ignition controller, etc., can solve the problems of low precision and accuracy, failure to achieve closed-loop control, precision and applicable working conditions, etc. Achieve the effect of high precision and accuracy, and unlimited applicable working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] specific implementation plan

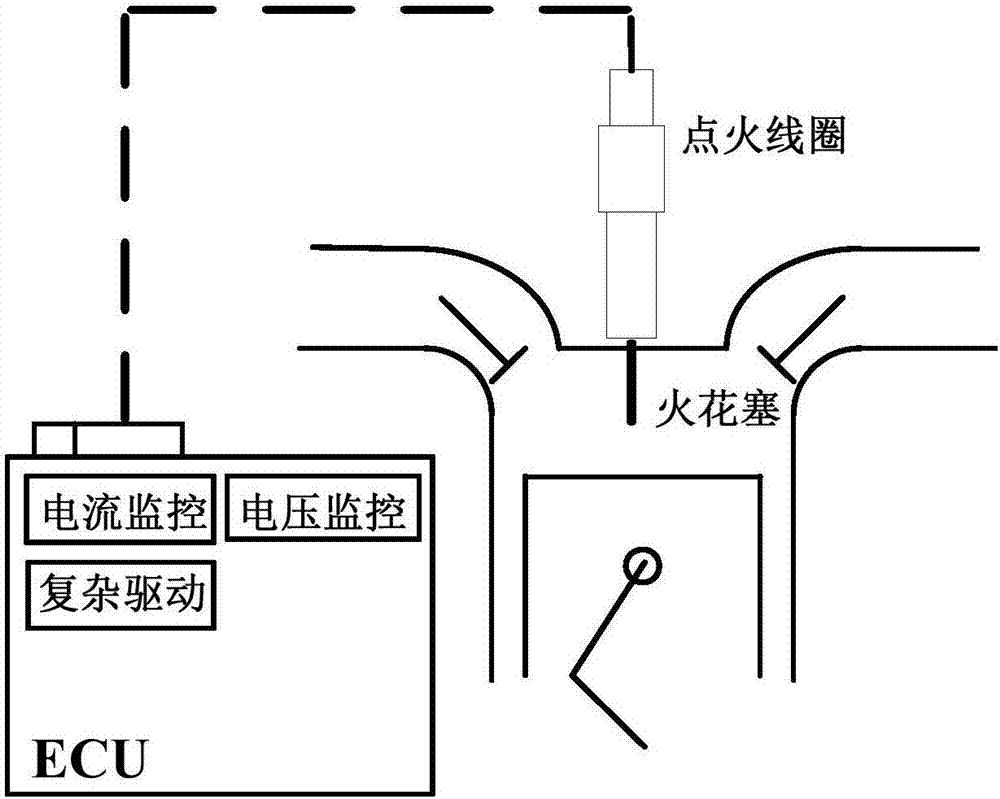

[0034] In order to achieve the purpose of cylinder-by-cylinder closed-loop control, the specific implementation of the ignition energy closed-loop control method for a natural gas engine of the present invention will be further described below in conjunction with the accompanying drawings.

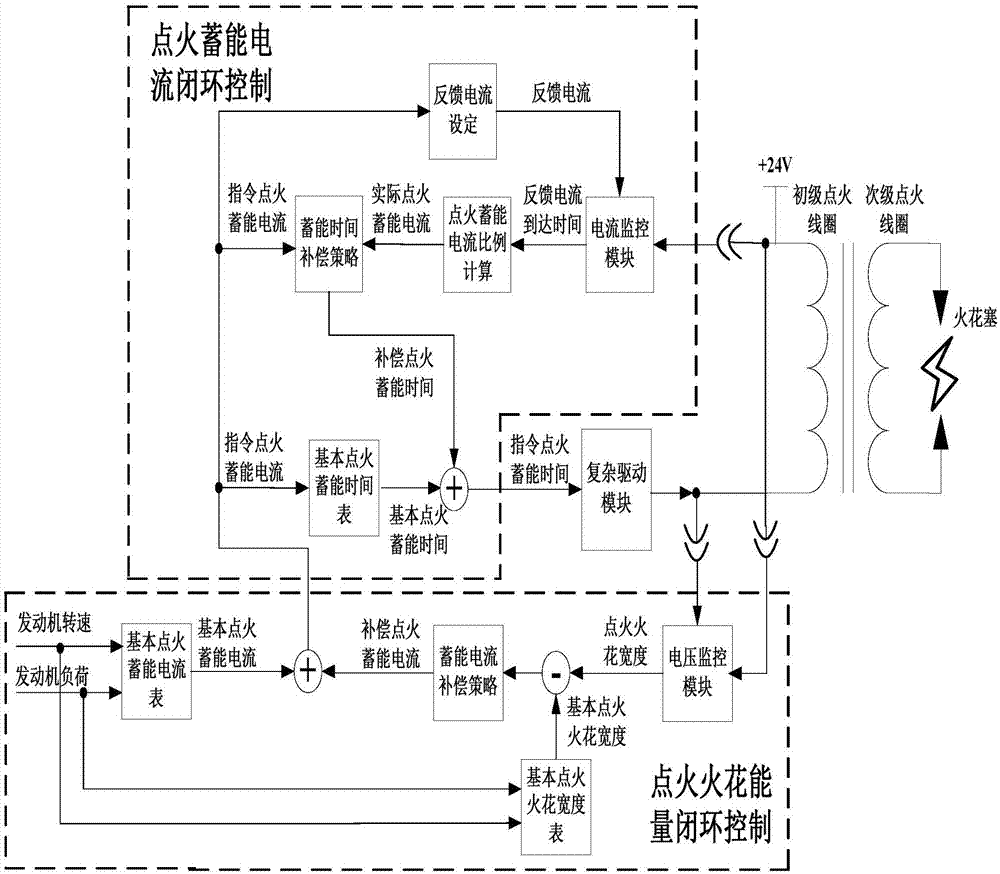

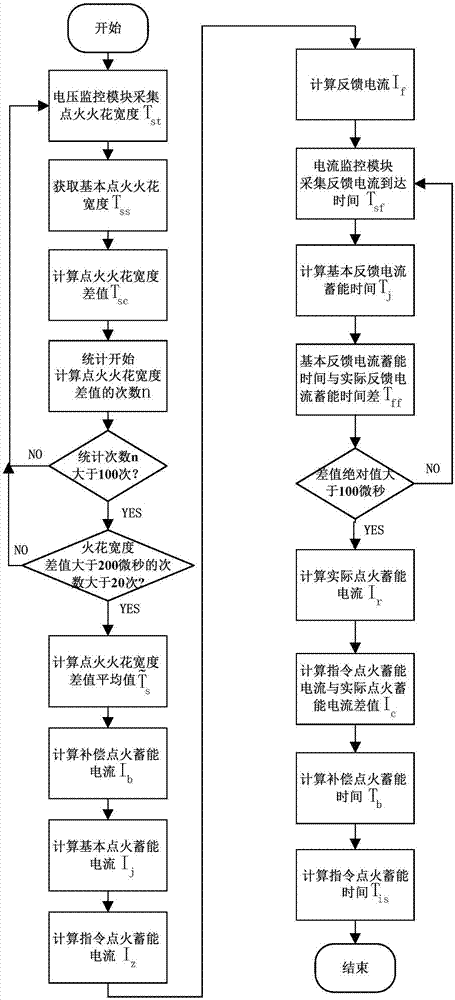

[0035] The method of the present invention includes primary ignition coil ignition energy storage current closed-loop control and spark plug spark ignition energy closed-loop control, and the ignition energy closed-loop control structure diagram is as follows figure 2 As shown, the process of the ignition energy closed-loop control method is shown in the soil; the spark plug ignition energy closed-loop control input is the ignition spark width, engine speed, and engine load obtained by the voltage monitoring module in the ECU, and the output command energy storage current is obtained through calculation; The primary ignition energy storage current clo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com