Electric heating device

A heating device, electric heating technology, applied in electric heating systems, household heating, heating methods, etc., can solve the problems of poor heating effect, not easy to bend, inconvenient maintenance, etc., to achieve good chemical stability, uniform heating, prolonged The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

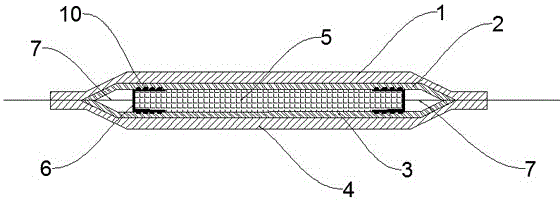

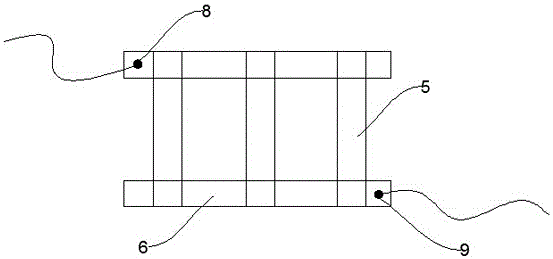

[0020] like figure 1 , figure 2 As shown, an electric heating and heating device described in this embodiment includes a first protective layer 1, a first adhesive layer 2, a heat generating layer, a second adhesive layer 3 and a second protective layer 4, and the heat generating layer is arranged on two Between the adhesive layers; the heating layer includes carbon nanotube film 5 and copper foil 6. There are two copper foils that do not intersect. The two copper foils are connected by three carbon nanotube films. Lines 7 are each provided with a positive power supply connection point 8 and a negative power supply connection point 9; the first protective layer, the first adhesive layer, the heating layer, the second adhesive layer and the second protective layer are heated by hot pressing. Bonded together, and the edges of the first protective layer and the second protective layer are bonded together by hot pressing, and the heating layer is wrapped in it to form a closed s...

Embodiment 2

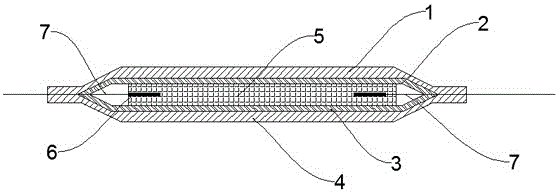

[0022] like image 3 As shown, an electric heating device described in this embodiment includes a first protective layer 1, a first adhesive layer 2, a heating layer, a second adhesive layer 3 and a second protective layer 4, and the heating layer includes carbon nanotubes Film 5, strip-shaped conductive cloth 6, two conductive cloths do not intersect, two strip-shaped conductive cloths are connected by two carbon nanotube films, a group of diagonal positions of the heating layer are respectively provided with a positive electrode through a power connection line 7 A power connection point and a negative power supply connection point; the first protective layer, the first adhesive layer, the heating layer, the second adhesive layer and the second protective layer are bonded together by hot pressing, and the first protective layer The edges of the layer and the second protective layer are bonded together by hot pressing, and the heating layer is wrapped in it to form a closed st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com