Pipeline cleaning system for grouting equipment of shield machine

A cleaning system and shield machine technology, which is applied in the field of shield machine grouting equipment pipeline cleaning system, can solve the problems of short solidification time, shield construction shutdown, shield construction shutdown loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

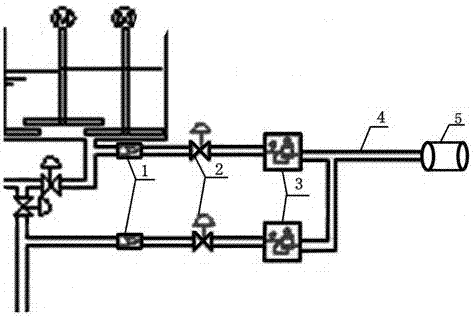

[0017] A check valve 1 , a solenoid valve 2 , a pressure reducing valve 3 and an air compressor 5 are connected sequentially through an air pipe 4 at the mouth of the slurry storage tank or the connection of the pipeline for liquid circulation. Wherein the gas outlet of the one-way valve is connected with the mouth of the slurry storage tank or the slurry circulation pipeline through the gas pipe. When working, the air compressor 5 sends compressed air to the pressure reducing valve 3 through the air pipe 4, and the air decompressed by the pressure reducing valve 3 enters the solenoid valve 2, and then blows into the mouth of the liquid tank or the interface of the pipeline through the check valve 1 , Play a role in preventing the clogging of the tank mouth.

[0018] Preferably, the solenoid valve is an eardrum solenoid valve.

[0019] Further, a control system can be set to control the start and stop of related operations, the control system is connected with the operating s...

Embodiment 2

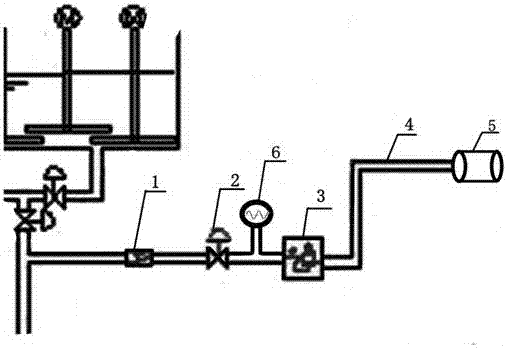

[0022] In the operating system of the grouting pipeline cleaning system in this embodiment, the air compressor 5 is connected to the pressure reducing valve 3 through the air pipe 4, the pulse meter 6 and the pressure reducing valve 3 are connected in parallel to the solenoid valve 2 through the air pipe 4, and the solenoid valve 2 passes through The air pipe 4 is connected to the one-way valve 1, and the water outlet of the one-way valve 1 is connected with the slurry circulation pipeline through the air pipe. The operating system of this embodiment is similar to the working principle of the operating system of Embodiment 1, the difference is that the alternate operation of water and air is controlled by the pulse instrument 6, which will cause air explosion in the pipeline and reduce the formation of liquid A hanging on the wall. The pipe of this method Road cleaning is cleaner than single-water cleaning, and it saves more water than single-water cleaning of pipelines.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com