Vibration reduction elevator and control method thereof

A technology for elevators and shock absorbers, which is applied to shock absorbers, springs/shock absorbers, elevators in buildings, etc. It can solve problems such as insufficient spring response, inconspicuous shock absorption effect, and inaccurate adjustment methods. Achieve obvious shockproof effect, reduce operation difficulty and labor intensity, and achieve variable rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

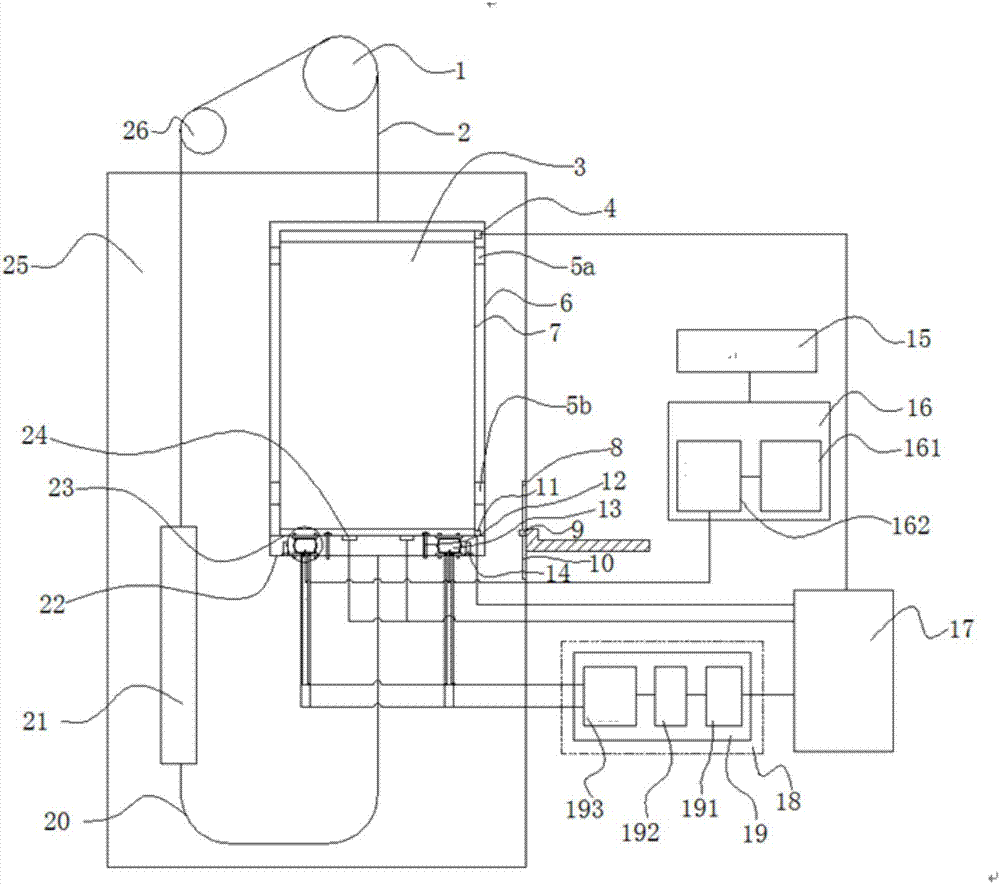

[0037] Such as figure 1 The shown elevator is provided with a shock absorbing device, including a hoisting device hoist 1 , a guiding device 26 , a sling 2 , a car 3 , a counterweight 21 , and a compensating device 20 . One end of the sling 2 is connected to the car 3 that can move vertically in the elevator shaft 25. After the sling has walked around the hoist and the guide, its other end is connected to the counterweight 21 that can move vertically in the elevator shaft. The car 3 is connected to a counterweight 21 through a compensating device 20 .

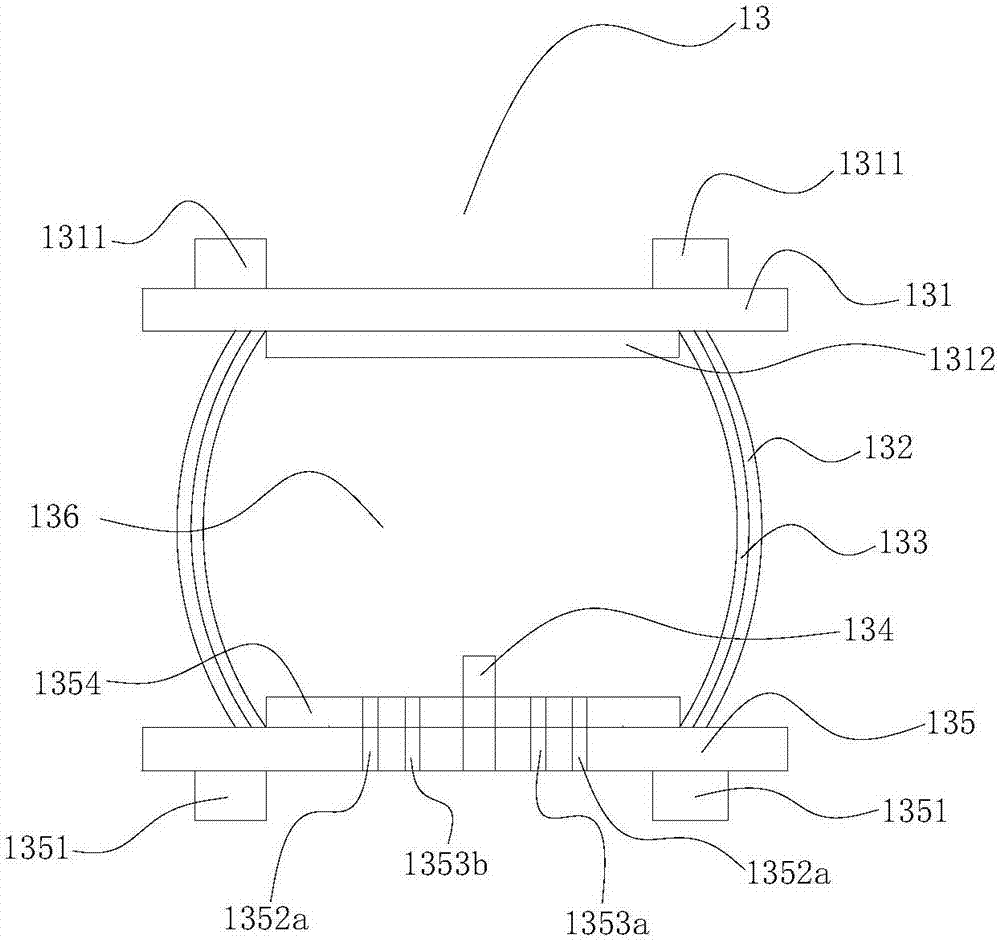

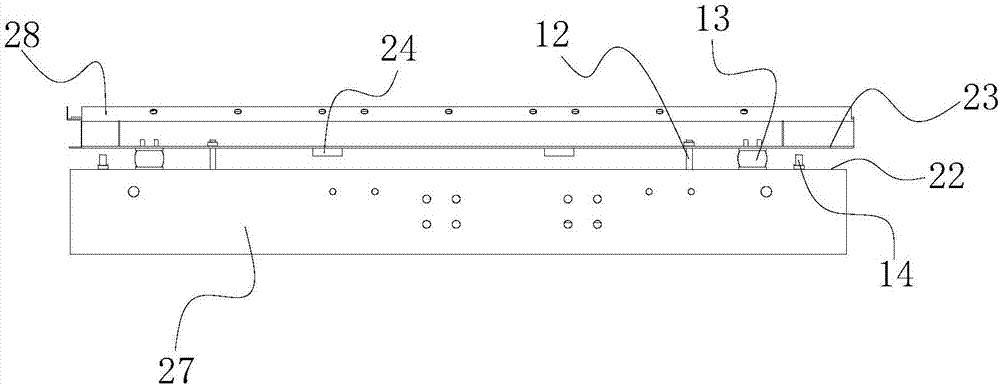

[0038] A damping device 13 is arranged between the car bottom 28 and the car bottom frame 27, which can be referred to figure 2 and image 3 , The damping device 13 is respectively provided with one at four corner positions in the space between the car bottom 28 and the car bottom frame 27 . The shock absorbing device 13 includes an upper connecting plate 131 , an outer layer of elastic material 132 , an inner layer of elas...

specific Embodiment 2

[0044] This embodiment adopts a kind of elevator provided with damping device in embodiment 1, and refer to Figure 4 The control flow chart of using the damping device to adjust the balance of the car after the elevator is installed is completed, and the action of the damping device 13 to adjust the balance of the car 3 is described. After the elevator is installed, the car 3 is located at the leveling position of the base station with no load, and is in an unloaded state. The car level sensing device 24 acquires the level status signal of the car 3 and inputs the signal to the control device 17 . The control device 17 determines the balanced state of the car 3 according to the input car 3 level state signal. The air valve 1352 and the exhaust valve 1353 charge and exhaust the damping device 13, and adjust the level of the car 3; during this process, the car level sensing device 24 continuously inputs the balance state signal of the car 3 The value control device 17 repeats...

specific Embodiment 3

[0045] This embodiment adopts a kind of elevator provided with damping device in embodiment 1, and refer to Figure 5 Adjust the car bottom leveling and car balance control process flow chart when the elevator is running in the normal running state of the elevator, and describe the actions of the shock absorber 13 to adjust the leveling of the car 3 and the balance control of the car 3 when the elevator is running. During the normal operation of the elevator, passengers are loaded and unloaded by the car 3, and the load capacity in the car 3 is different, which causes the height of the shock absorbing device 13 with adjustable height to change, causing the height of the car bottom 28 to change accordingly, resulting in leveling. The position changes and the car 3 is unbalanced; or when the car 3 loads and unloads passengers, the passenger positions are different, which will also cause the car 3 to be unbalanced. When the elevator loads and unloads passengers, the door opening ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com