A kind of low-temperature batch synthesis method of black phosphorus nanosheet material

A technology for nanosheets and black phosphorus is applied in the field of low-temperature batch synthesis of black phosphorus nanosheet materials, which can solve the problems of easy oxidation, time-consuming and high cost of products, and achieve the effects of simple and convenient preparation method, stable chemical properties and increased yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

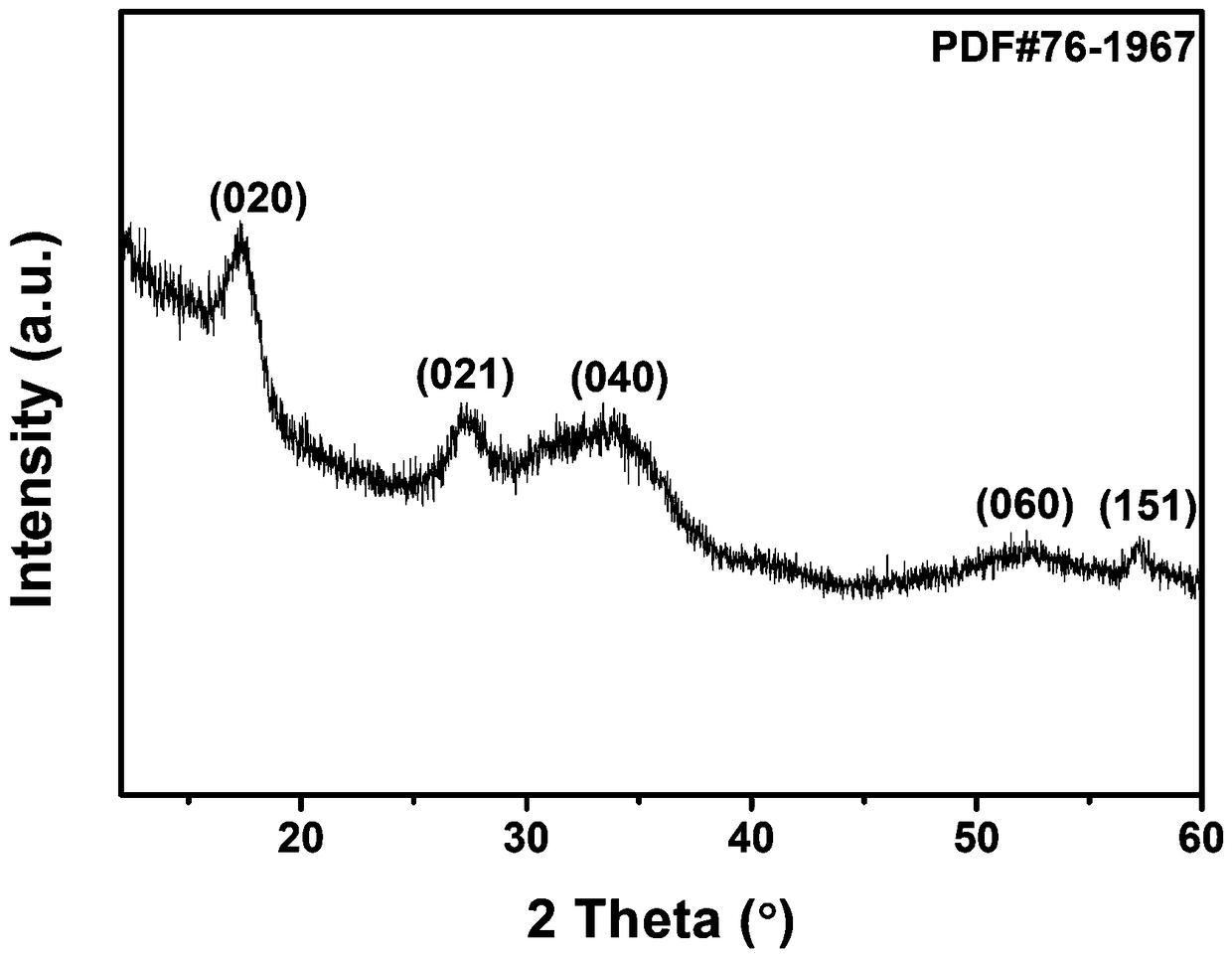

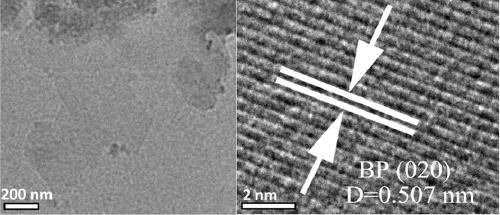

Embodiment 1

[0017] (1) Weigh 3g of white phosphorus and add it into a reaction kettle containing 70mL of ethylenediamine, and magnetically stir to completely dissolve the white phosphorus;

[0018] (2) Tighten the lid of the reaction kettle, place it in an oven and heat it to 140°C, and keep the temperature constant for 12 hours;

[0019] (3) After the reaction kettle is spontaneously cooled to room temperature, the obtained product is centrifuged and washed with benzene, ethanol and deionized water;

[0020] (4) The obtained black precipitate was placed in a vacuum drying oven, and dried at room temperature for 12 hours to obtain the black phosphorus nanosheet material.

Embodiment 2

[0022] Weigh 2g of white phosphorus and add it into a reaction kettle filled with 60mL of ethylenediamine, and magnetically stir to completely dissolve the white phosphorus. The rest of the conditions are the same as in Example 1, and the black phosphorus nanosheet material is obtained after testing.

Embodiment 3

[0024] Weigh 3g of white phosphorus and add it into a reaction kettle containing 70mL of ethylenediamine, stir magnetically to completely dissolve the white phosphorus; tighten the lid of the reaction kettle, and place it in an oven to heat to 120°C and keep the temperature constant for 12 hours; The conditions are the same as in Example 1, and the black phosphorus nanosheet material is obtained after detection.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com