A self-assembled nano-oxynitride high temperature resistant coating and its preparation method

An oxynitride, self-assembly technology, applied in coating, nanotechnology, metal material coating process, etc., can solve problems such as poor mechanical properties such as hardness and toughness, achieve good adaptability, good thermal stability, reduce The effect of cutting friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

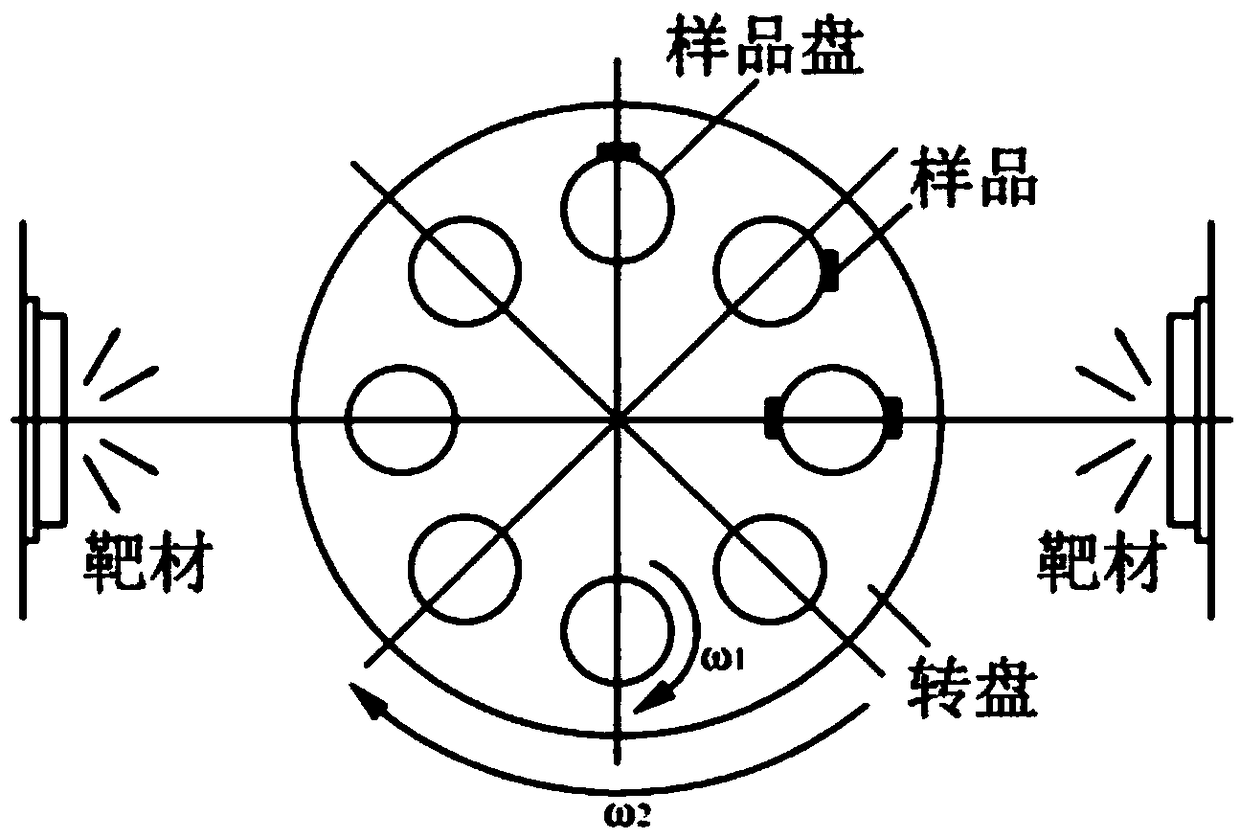

Method used

Image

Examples

Embodiment 1

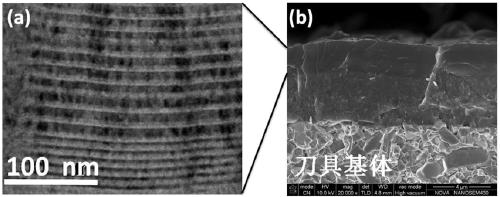

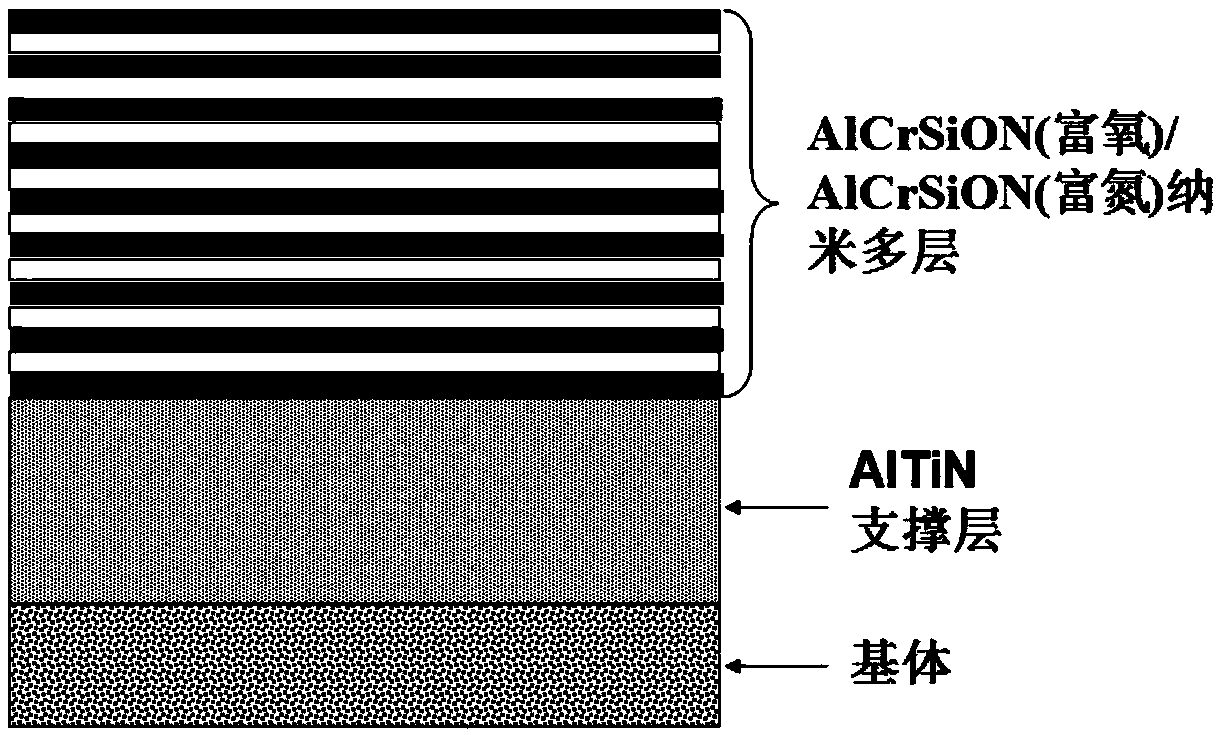

[0034] A self-assembled nanometer multilayer oxynitride high temperature resistant coating comprises an AlTiN support layer, an AlCrSiON oxygen-enriched layer and an AlCrSiON nitrogen-enriched layer. The atomic percent content of each element in the AlTiN support layer is: Al: 28 at.%, Ti: 16 at.%, N: 56 at.%. The thickness of the oxygen-rich layer is 2nm, the thickness of the nitrogen-rich layer is 5nm, the atomic percentage content of each element in the coating is: Al: 20at.%, Cr: 10at.%, Si: 15at.%, O: 50at.%, N : 5 at.%.

[0035] Polish the cemented carbide, ultrasonically clean it with acetone and alcohol for 10 minutes, dry it with nitrogen, and put it into a vacuum chamber. Turn on the heater to raise the temperature to 250°C, and evacuate the vacuum chamber to a vacuum degree of 1.0×10 -3Below Pa. 350 sccm of Ar gas was introduced, the bias voltage of the workpiece support was set to -1000V, and the substrate surface was cleaned by sputtering, and the bombardment t...

Embodiment 2

[0040] A self-assembled nanometer multilayer oxynitride high temperature resistant coating comprises an AlTiN support layer, an AlCrSiON oxygen-enriched layer and an AlCrSiON nitrogen-enriched layer. The atomic percent content of each element in the AlTiN support layer is: Al: 27 at.%, Ti: 17 at.%, N: 56 at.%. The thickness of the oxygen-rich layer is 8nm, the thickness of the nitrogen-rich layer is 30nm, the atomic percentage content of each element in the coating is: Al: 25at.%, Cr: 15at.%, Si: 5at.%, O: 5at.%, N : 50at.%.

[0041] Polish the cemented carbide, ultrasonically clean it with acetone and alcohol for 15 minutes, then dry it with nitrogen and put it into a vacuum chamber. Turn on the heater to raise the temperature to 350°C, and evacuate the vacuum chamber to a vacuum degree of 5.0×10 -3 Below Pa. 250 sccm of Ar gas was introduced, the bias voltage of the workpiece support was set to -800V, and the surface of the substrate was cleaned by sputtering, and the bom...

Embodiment 3

[0046] A self-assembled nano-oxynitride high-temperature resistant coating comprises an AlTiN support layer and an AlCrSiON (oxygen-enriched) / AlCrSiON (nitrogen-enriched) functional layer. The atomic percent content of each element in the AlTiN support layer is: Al: 28 at.%, Ti: 15 at.%, N: 57 at.%. The thickness of the oxygen-rich layer is 12nm, and the thickness of the nitrogen-rich layer is 60nm. The atomic percentage content of each element in the coating is: Al: 30at.%, Cr: 20at.%, Si: 10at.%, O: 15at.%, N :25 at.%. Polish the cemented carbide, ultrasonically clean it with acetone and alcohol for 15 minutes, then dry it with nitrogen and put it into a vacuum chamber. Turn on the heater to raise the temperature to 400°C, and evacuate the vacuum chamber to a vacuum degree of 5.0×10 -3 Below Pa. 300 sccm of Ar gas was introduced, the bias voltage of the workpiece support was set at -900V, and the surface of the substrate was cleaned by sputtering, and the bombardment time...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com