Ray space angle position finder

A technology of ray space and locator, which is applied in the direction of instruments, measuring angles, measuring devices, etc., can solve the problem of small coating angles, achieve high accuracy, improve coating quality, and improve process precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

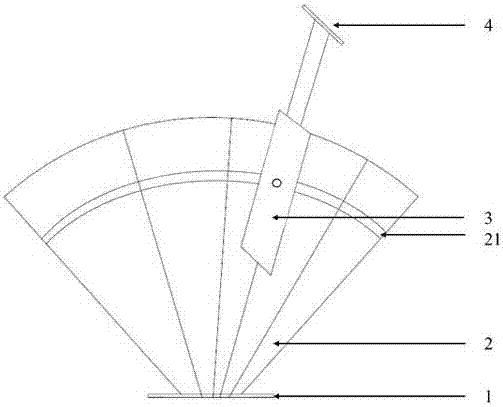

[0021] The ray space angle locator of this embodiment, such as figure 1 As shown, it includes a circular base 1, and an angle plate 2 that can rotate 360 degrees is arranged on the upper end of the circular base 1, and the angle plate 2 is a fan-shaped structure with a central angle of 30-180°. The accuracy of the angle plate 2 0.1° to 1°; the circular base 1 is provided with a rotating shaft passing through the angle disc 2 in the middle, and the angle disc 2 rotates 360 degrees around the rotating shaft.

[0022] The angle disk is a fan-shaped structure with a central angle of 30° to 180°, so that the range of the angle between the substrate and the target source rays can be wider, and it can be used to control the angle between the substrate and the target source rays in different ranges.

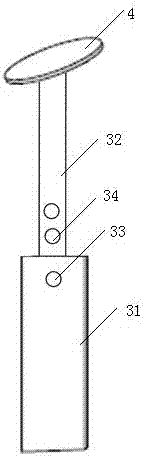

[0023] On the angle plate 2, there is a sliding guide groove 21 arranged along the arc extension direction of the angle plate 2, and a movable telescopic arm 3 is also arranged on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com