Hydraulic cavitation generating device and hydraulic cavitation generating method

A generation device, hydraulic cavitation technology, applied in the method of using atmospheric pressure to chemically change substances, chemical instruments and methods, water/sewage treatment, etc., can solve the problem of triggering or intensifying physical and chemical reactions, Solve the problems of large piping structure of the system and small processing capacity of the cavitation reactor to achieve low equipment manufacturing costs, reduce scale and complexity, and reduce input costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

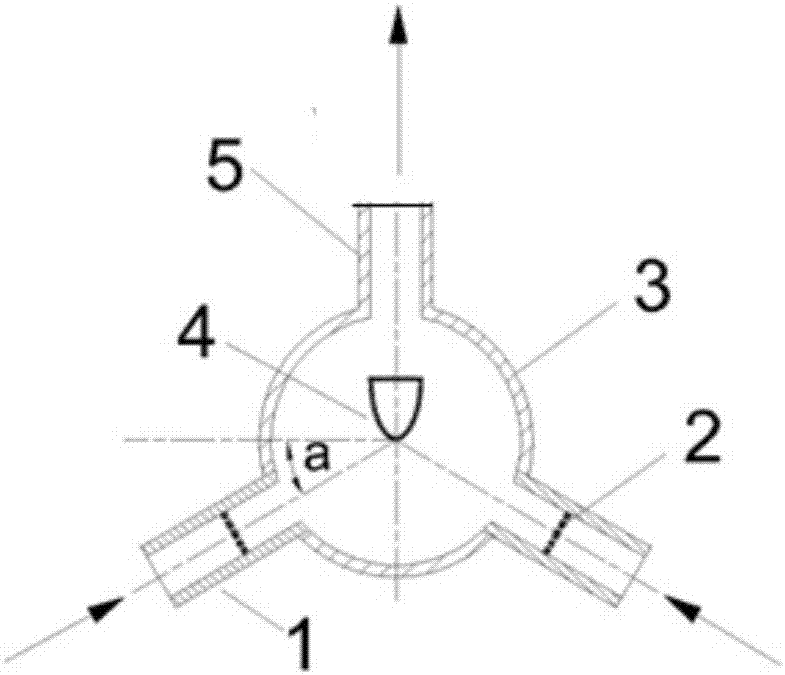

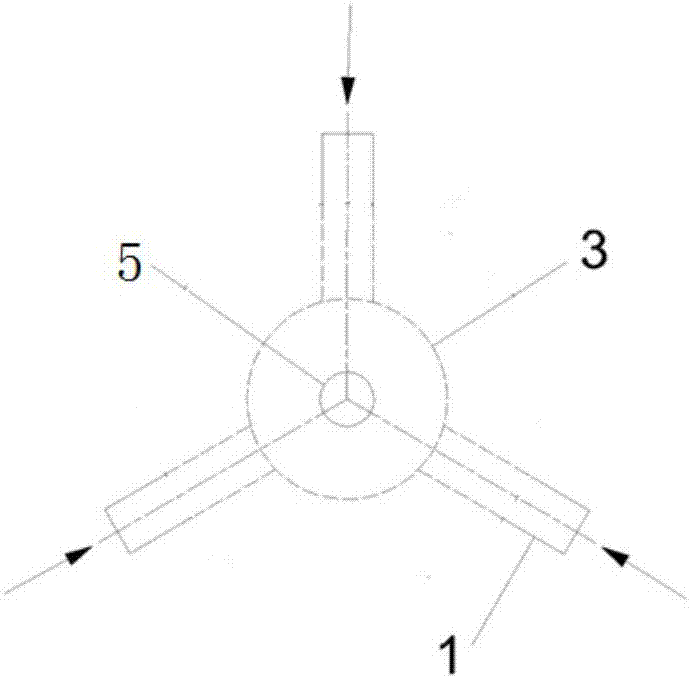

[0035] like Figure 1-2 As shown, a hydraulic cavitation generating device includes a fluid inlet pipe 1, an orifice plate 2, a spherical cavity 3, a cavitation enhancement module 4, a fluid outlet pipe 5, and a plurality of fluid inlet pipes 1 ( figure 1 The middle fluid inlet pipe 1 is provided with two, figure 2 The middle fluid inlet pipe 1 is provided with three) connected with the lower half of the spherical cavity 3, and the axis of each fluid inlet pipe 1 inlet pipe passes through the center of the spherical cavity 3, and all form an angle a (a is 0 degree) with the horizontal direction ~80 degrees), there are at least two fluid inlet pipes 1, which are evenly distributed a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com