Hybrid electric vehicle power system

A hybrid electric vehicle and power system technology, applied in the field of hybrid electric vehicle power system, can solve the problems of high cost, low working efficiency of driving motor, easy high temperature and heat generation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

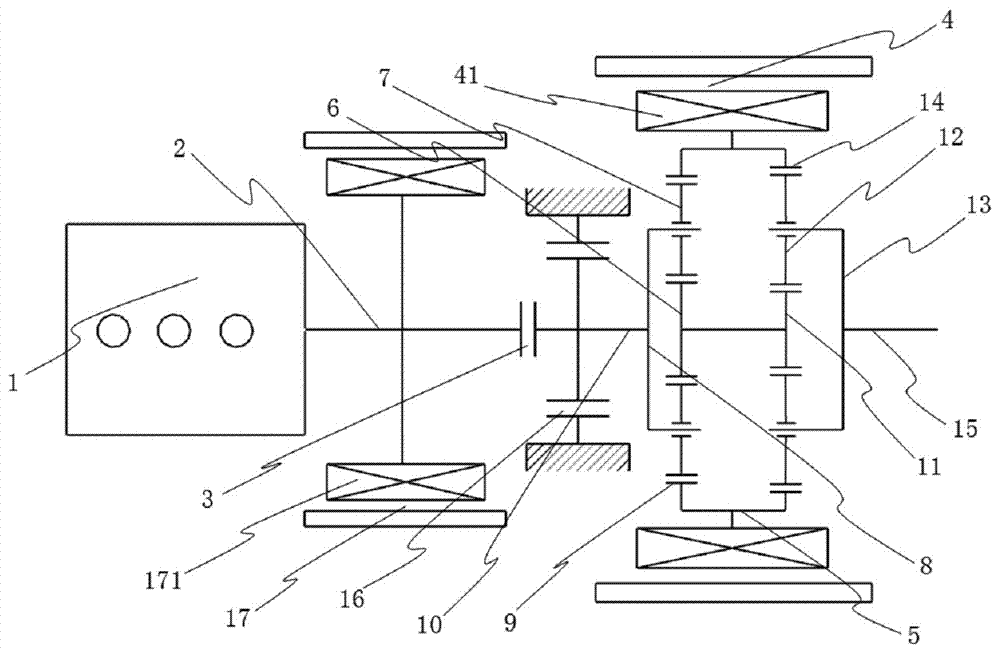

[0008] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0009] see figure 1 , the hybrid vehicle power system of the present invention includes an engine 1 comprising a crankshaft 2, a clutch 3, a drive motor 4 comprising a motor rotor 41, an output shaft 15, and its first sun gear 6 is located within the first planet carrier 8, The first planetary gear 7 is rotatably mounted on the first planetary carrier 8 , the first ring gear 9 is located in the first planetary row outside the first planetary carrier 8 , and the right end of the crankshaft 2 of the engine 1 is coupled with the clutch 3 . Depend on figure 1 It can be seen that the present invention also includes an outer ring 5, a connecting shaft 10, a brake 16, an ISG generator 17 including an ISG motor rotor 171, and its second sun gear 11 is located inside the second planetary carrier 13, and the second planetary gear 12 can be The second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com