Water-based gel material for back surface of ceramic tile and preparation method for water-based gel material

A technology of gelling material and water-based glue, applied in the field of architectural decoration, can solve problems such as unsuitability for vitrified porcelain, and achieve the effects of enhancing the sticking effect, increasing the sticking area, and convenient construction and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

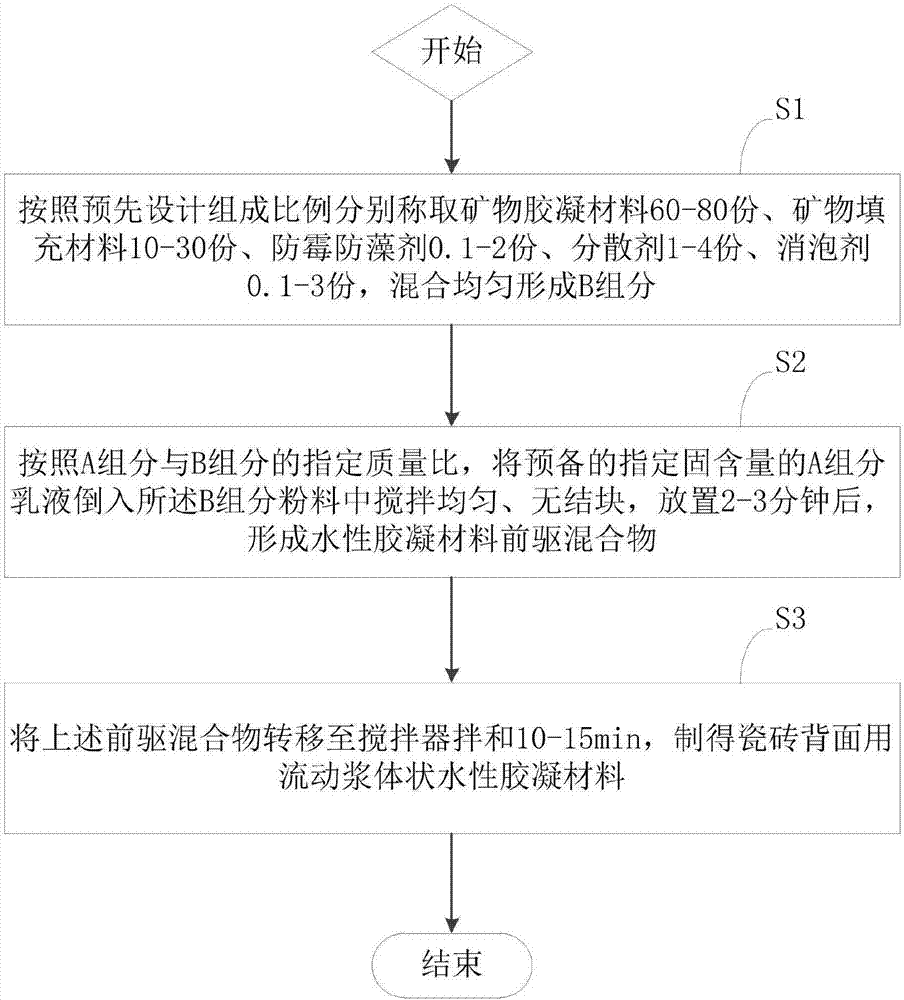

[0039] refer to figure 1 , the embodiment of the present invention also provides a method for preparing a water-based cementitious material on the back of a tile, including:

[0040] S1: Weigh 60-80 parts of mineral gelling material, 10-30 parts of mineral filling material, 0.1-2 parts of anti-mold and anti-algae agent, 1-4 parts of dispersant, and 0.1-3 parts of defoaming agent according to the pre-designed composition ratio parts, mix evenly to form component B;

[0041] S2: According to the specified mass ratio of component A to component B, pour the prepared emulsion of component A with a specified solid content into the powder of component B and stir evenly without agglomeration. After standing for 2-3 minutes, Forming a water-based cementitious material precursor mixture;

[0042] S3: Transfer the above precursor mixture to a stirrer and stir for 10-15 minutes to prepare a fluid slurry-like water-based gelling material for the back of the tile.

[0043] Preferably, th...

Embodiment 1

[0046] Example 1: Weigh 60 parts of mineral gelling material, 15 parts of mineral filling material, 0.1 part of anti-mildew and anti-algae agent, 1 part of dispersant, and 0.05 part of defoamer, and mix them uniformly to form component B; pre-mixed solid content 45% styrene-acrylate emulsion is component A; according to the mass ratio of component A to component B is 1:1.5, pour the emulsion of component A into the powder of component B and stir evenly without agglomeration After standing for 2 minutes, transfer to a stirrer and stir for 10 minutes to prepare a fluid slurry-like water-based gelling material for the back of the tile, which is marked as a water-based gelling material.

Embodiment 2

[0047] Example 2: Weigh 70 parts of mineral gelling material, 20 parts of mineral filling material, 1 part of anti-mildew and anti-algae agent, 2 parts of dispersant, and 1 part of defoamer, and mix them uniformly to form component B; the pre-mixed solid content 50% acrylate emulsion is component A; according to the mass ratio of component A to component B as 1:1.4, pour the emulsion of component A into the powder of component B and stir evenly without agglomeration, and place it for 3 After 10 minutes, transfer to a stirrer and stir for 15 minutes to prepare a fluid slurry-like water-based cementitious material for the back of the tile, which is marked as b water-based cementitious material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com