Viscosity-controllable thermal conductive interface material as well as preparation method and application thereof

An interface material and viscous technology, applied in heat exchange materials, chemical instruments and methods, modification by conduction heat transfer, etc., can solve problems such as reducing thermal conductivity of materials, and achieve good material compression performance, small thermal resistance, and preparation. Simple and easy method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] This embodiment provides a method for preparing a thermally conductive interface material with controllable viscosity, which includes the following steps:

[0043] Mix the silicone resin and micron-sized heat-conducting powder spherical alumina at a mass ratio of 10:90, and mix thoroughly to obtain the body glue material;

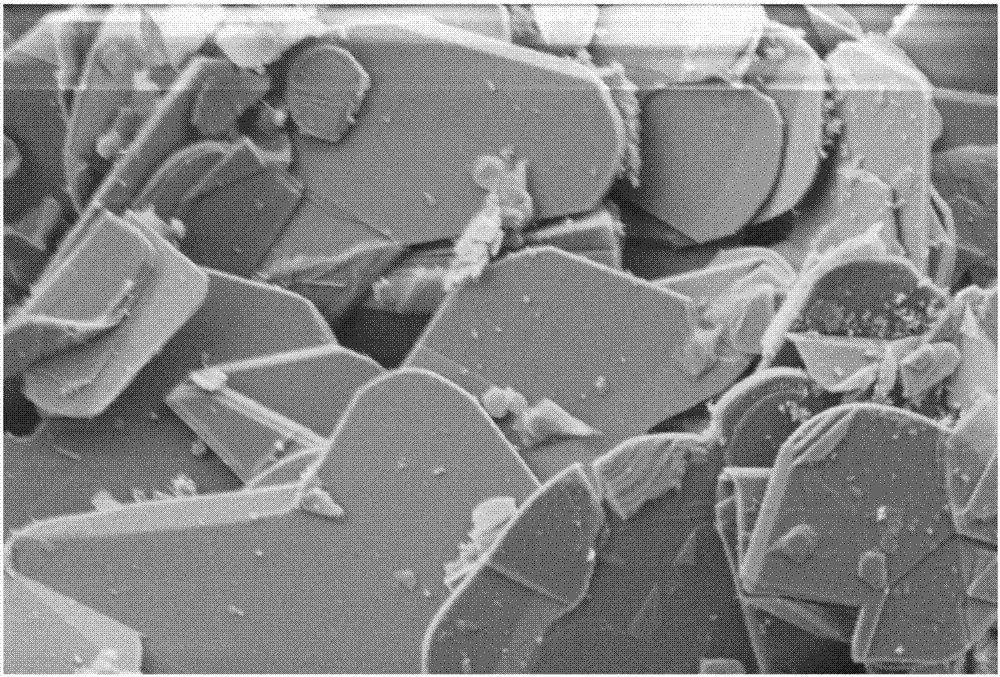

[0044] Mix silicone resin and nano-scale heat-conducting powder flake-shaped boron nitride in a mass ratio of 95:5 to form a surface coating raw material;

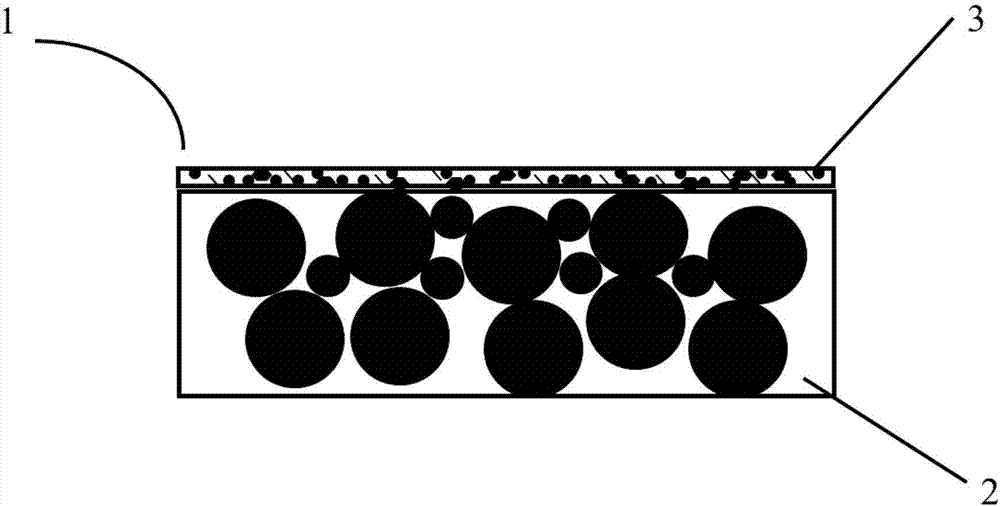

[0045] Coat the raw material glue of the surface coating on the surface of the thermal interface material body glue, and then form a film at room temperature, and then cure it at 120°C for 25 minutes to form a tightly bonded surface coating 3 and heat conduction body layer 2 , to obtain a thermally conductive interface material 1 with controllable viscosity, its structure is as follows figure 1 shown.

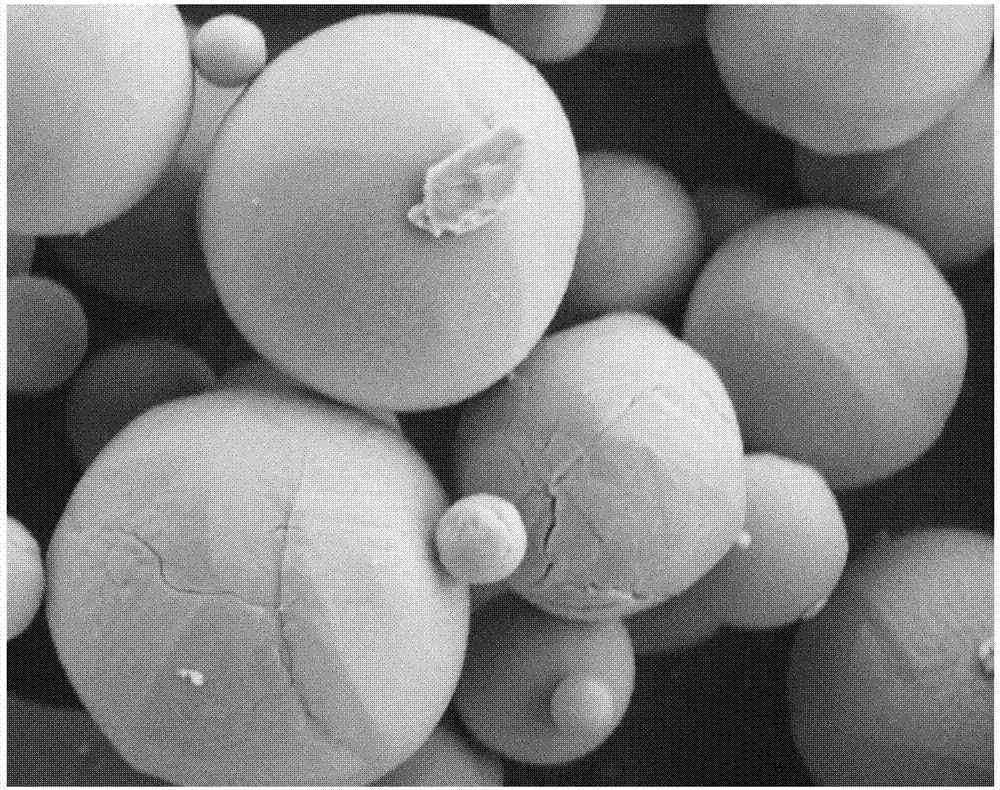

[0046] Among them, the scanning electron microscope image of spherical alumina is shown in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com