Hard facing alloy material

A hard surface alloy and hardness technology, which is applied in the field of alloy materials, can solve the problems that hard surface alloy materials cannot meet the needs of various application surfaces and use environments, and achieve the effect of protecting functionality and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

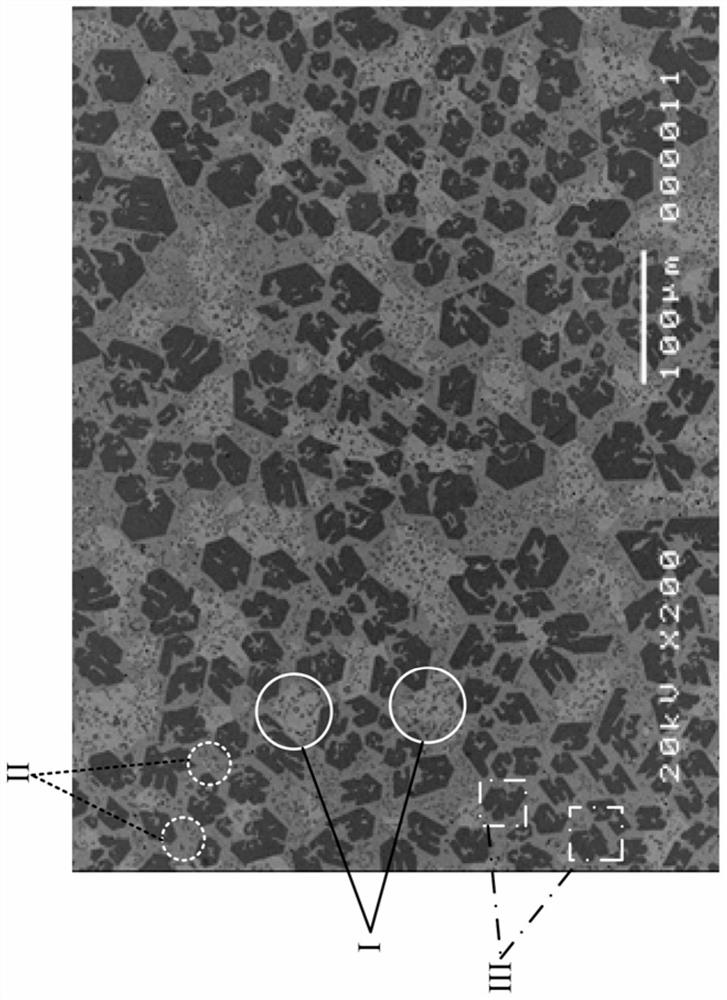

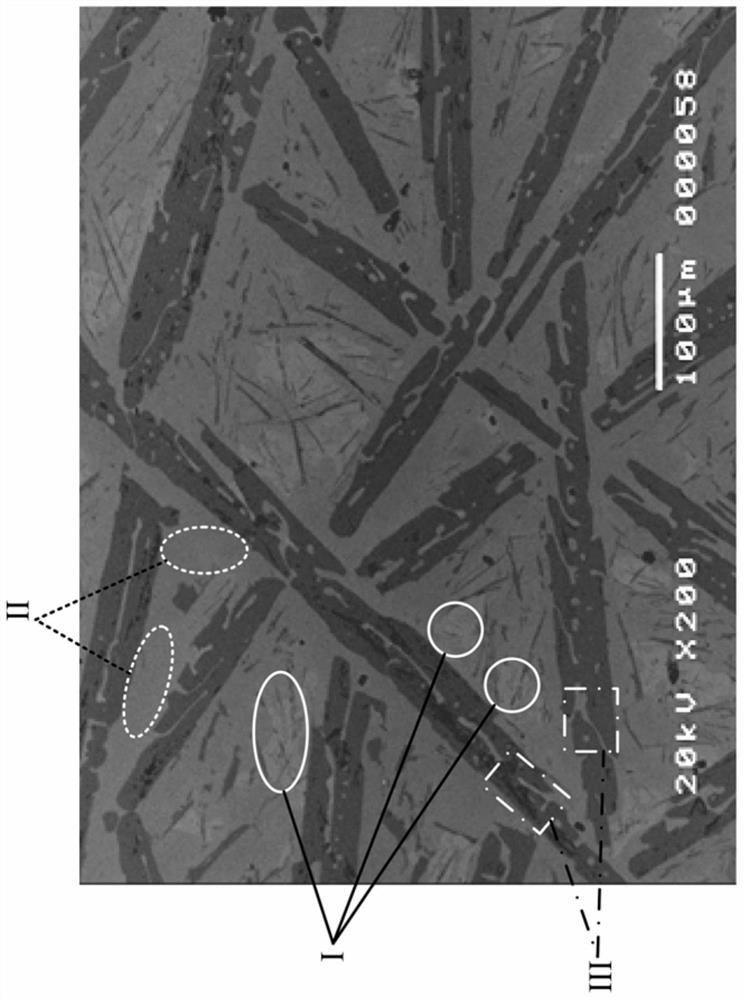

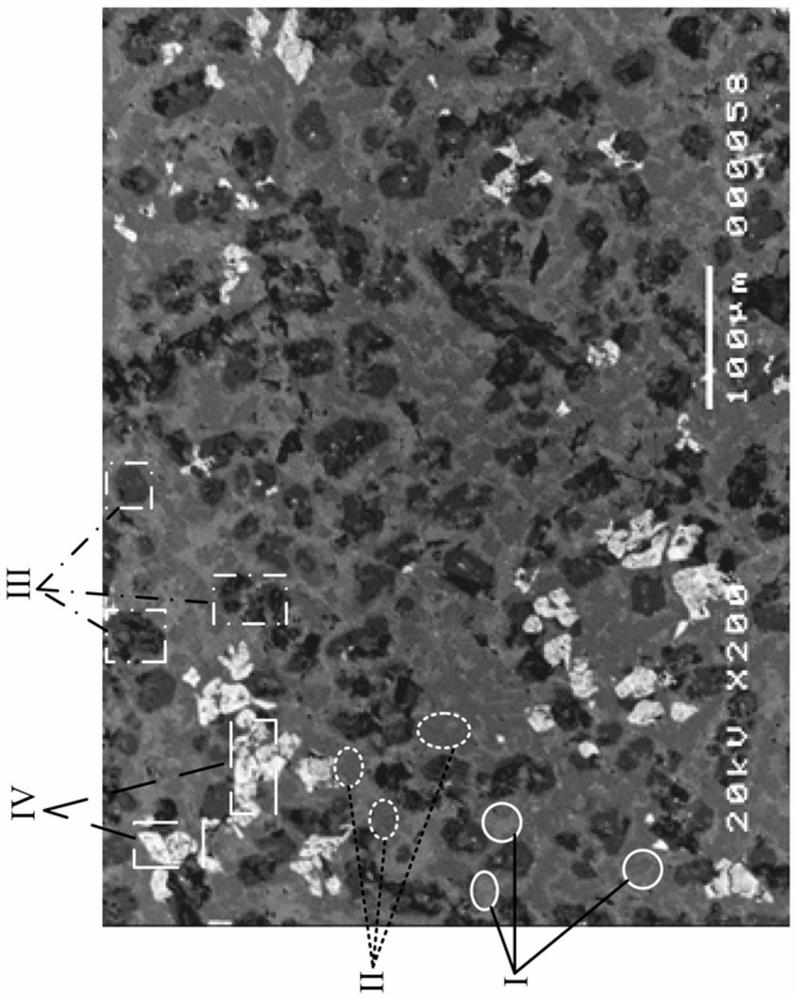

[0029] In order to more clearly describe a hard surface alloy material proposed by the present invention, the preferred embodiments of the present invention will be described in detail below with reference to the drawings.

[0030] The invention provide a hard-faced alloy material consisting of at least one base phase structure and at least one reinforce phase structure, and that hard-faced alloy material has a specific hardness which is greater than HV500. Particularly, the hard surface alloy material of the present invention must contain more than four main metal elements, and the main metal elements are selected from the following groups: aluminum (Al), cobalt (Co), chromium (Cr), copper (Cu), iron (Fe), manganese (Mn), molybdenum (Mo), nickel (Ni), niobium (Nb), and niobium (Nb). In addition, the hard surface alloy material further contains at least one nonmetallic element selected from the following groups: boron (b), carbon (c), nitrogen (n), oxygen (o) and Silicon (si).

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com